Advantages of Leizhen as Your Trusted PET Preform Mold Manufacturer

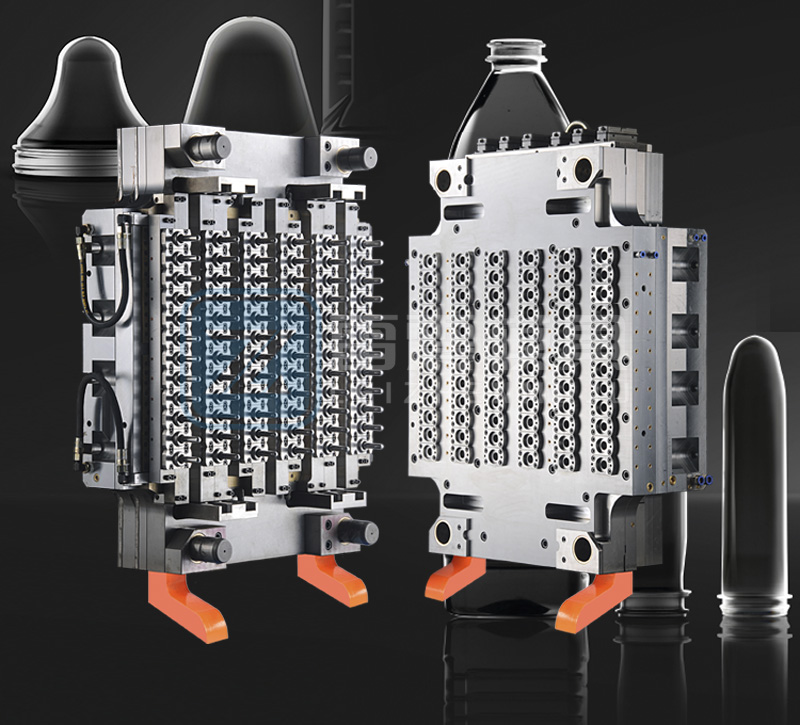

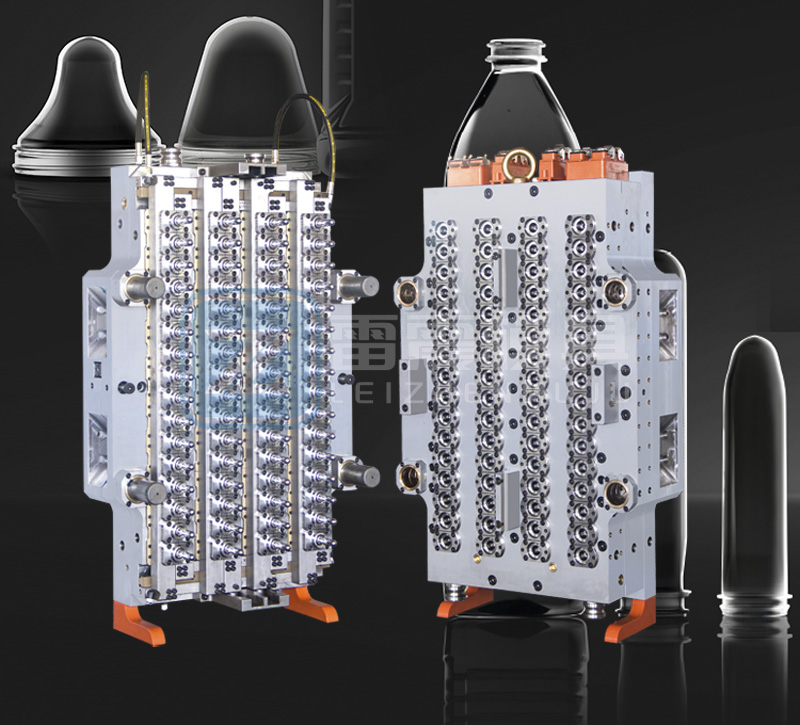

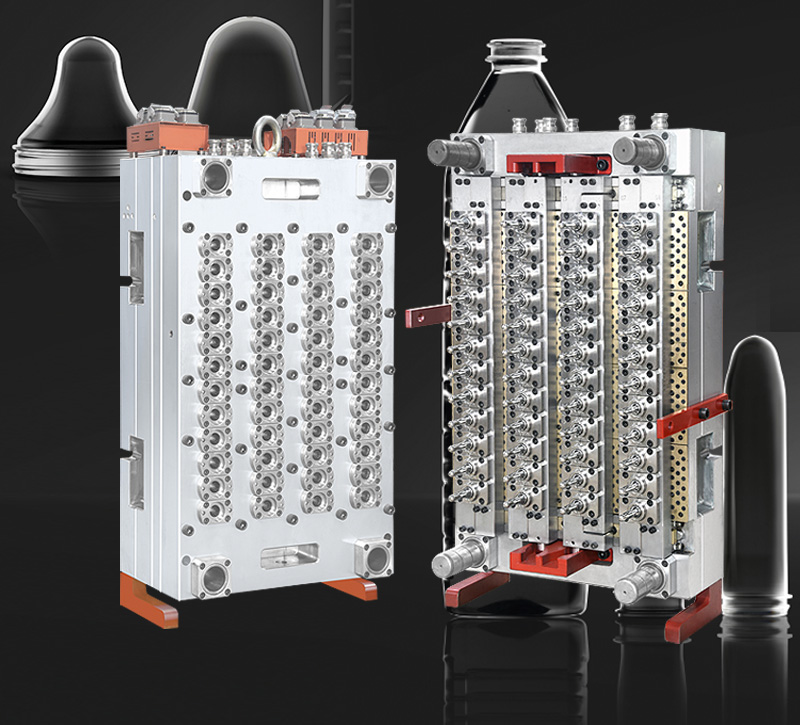

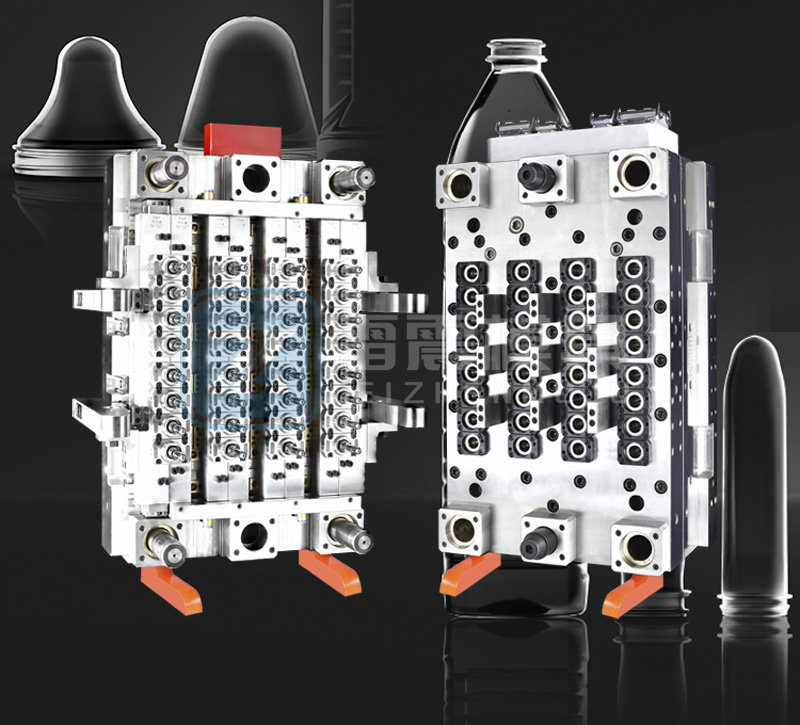

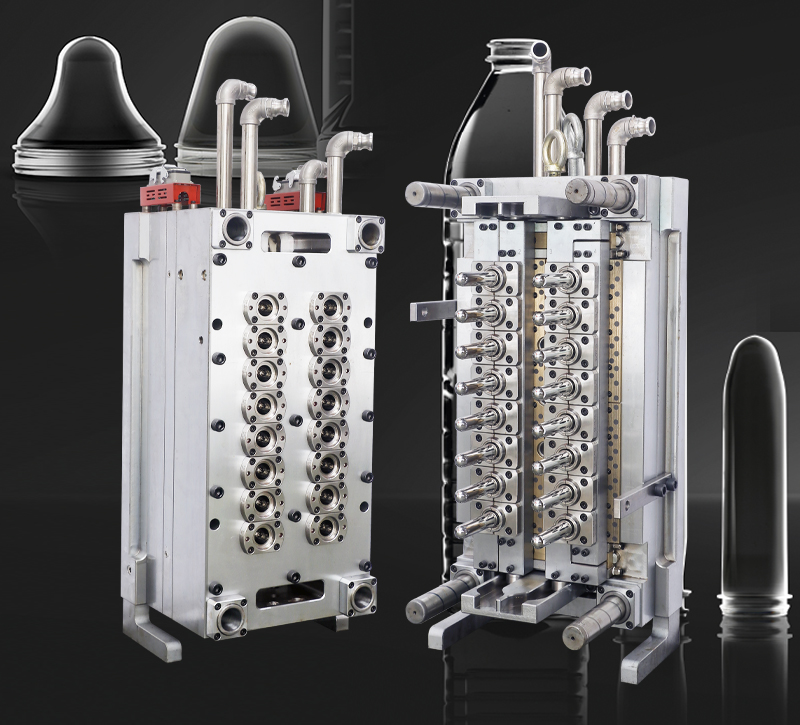

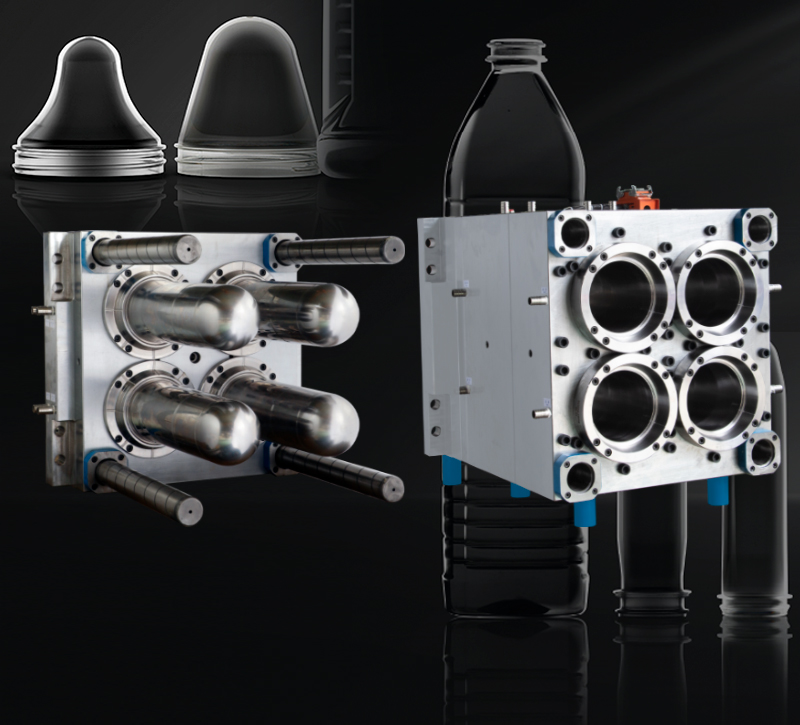

Leizhen Mould stands out as a leading PET preform mold manufacturer, offering unmatched expertise, innovation, and reliability in injection mold production. With years of industry experience, we specialize in high-precision, durable molds designed to optimize efficiency and reduce production costs. Our customizable solutions cater to diverse industries, including beverages, pharmaceuticals, and cosmetics, ensuring perfect compatibility with your specific bottle designs and closure systems.

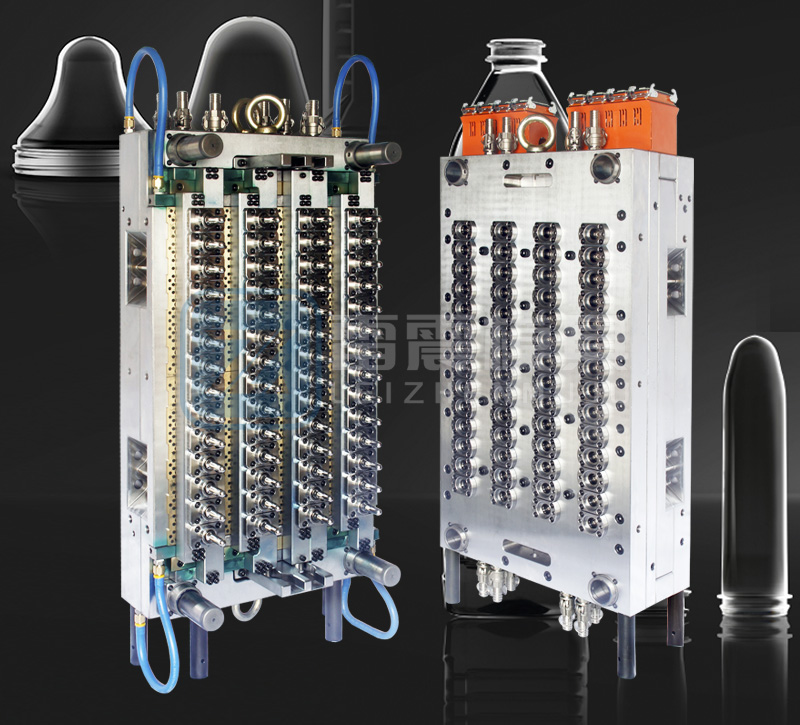

We utilize premium steel alloys and advanced hot runner technology to enhance mold longevity, minimize material waste, and improve energy efficiency. Every mold undergoes rigorous testing to guarantee flawless performance in high-volume production environments. As an ISO-certified manufacturer, we adhere to strict quality control measures, delivering consistent, defect-free molds that meet global standards.

Beyond superior craftsmanship, we provide comprehensive support, from initial design consultation to after-sales service, ensuring seamless integration into your production line. Our commitment to sustainability means we develop molds that support recyclable PET materials, helping you meet eco-friendly packaging demands.

Choosing Leizhen means investing in precision, durability, and innovation—partner with us to elevate your PET packaging production with world-class molds.

Contact us today to discuss your project and experience the Leizhen advantage!

Leizhen Mould

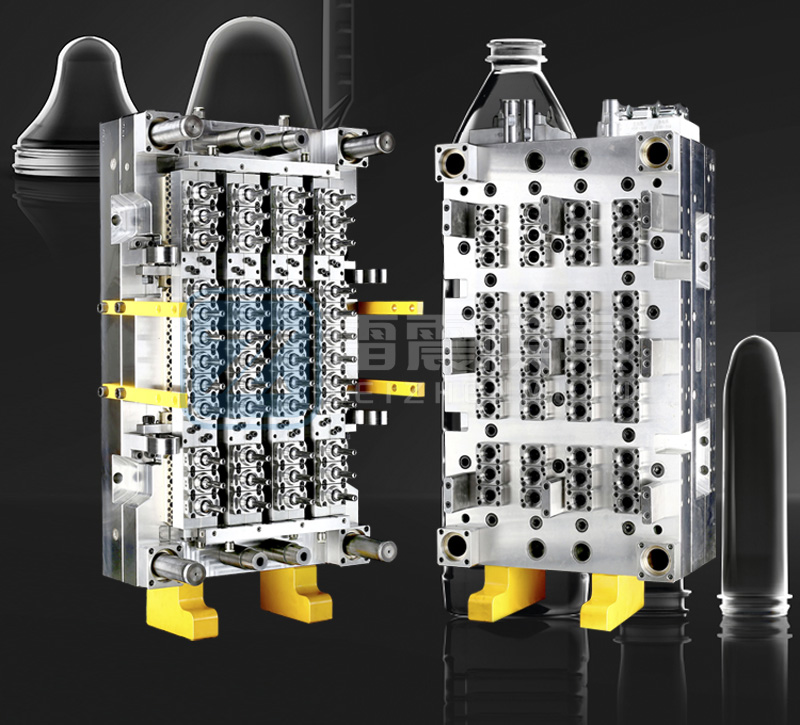

Strict mold trial process - ensure that 100% of preform molds are qualified before leaving the factory

Raw material matching test

Use customer-specified raw materials (such as PET, PP, etc.) for injection molding tests to verify the compatibility of molds and materials. Record parameters such as melt fluidity and shrinkage to ensure uniformity of preform wall thickness (±0.02mm accuracy).

Molding parameter optimization

Adjust injection pressure (800-1500bar), temperature (260-300℃), cooling time, etc. to eliminate defects such as flash and bubbles. Use mold flow analysis software (Moldflow) to simulate the filling process, optimize gate design, and reduce stress concentration.

Mold trial report delivery

Provide a complete report including pressure curve chart, defect analysis, and process parameter table to support customers' rapid introduction to mass production.