PET Preform Mold & Pet Preform Hot Runner Molds In China

16-Cavity Preform Mold in Stable Production | High-Efficiency PET Mold

Our 16-cavity preform mold is operating under normal, stable production, ensuring high-volume output ...

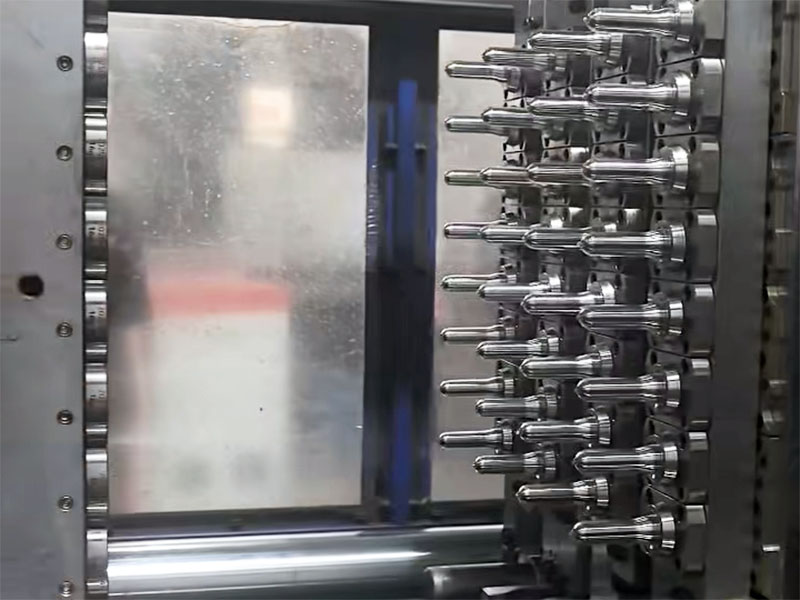

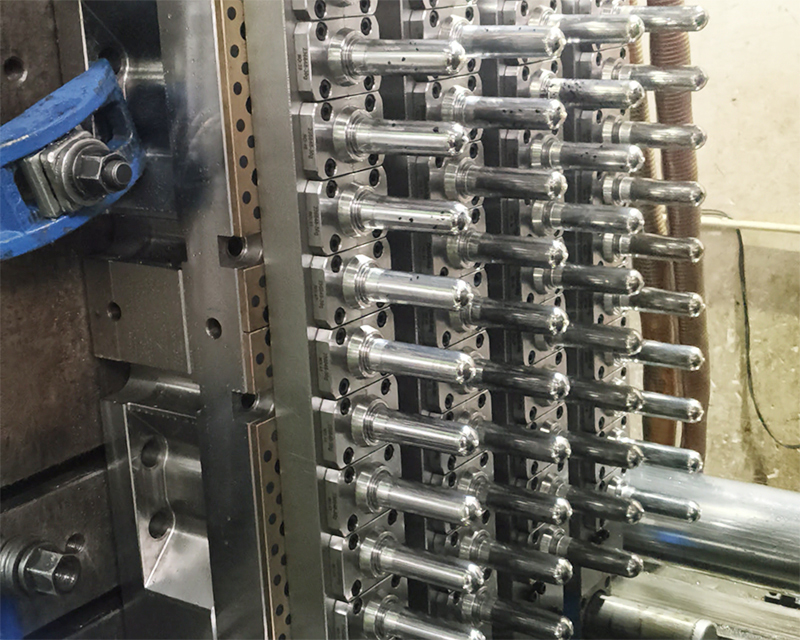

Precision-Engineered 32-Cavity PET Preform Injection Mold

This 32-cavity mold is a benchmark in high-cavitation mold technology, built for unmatched productivi...

Jar Preform Injection Mould Manufacturers, Wholesale Factory

A PET preform mould manufacturer. With 10years of technology and manufacturing experience of PET pref...

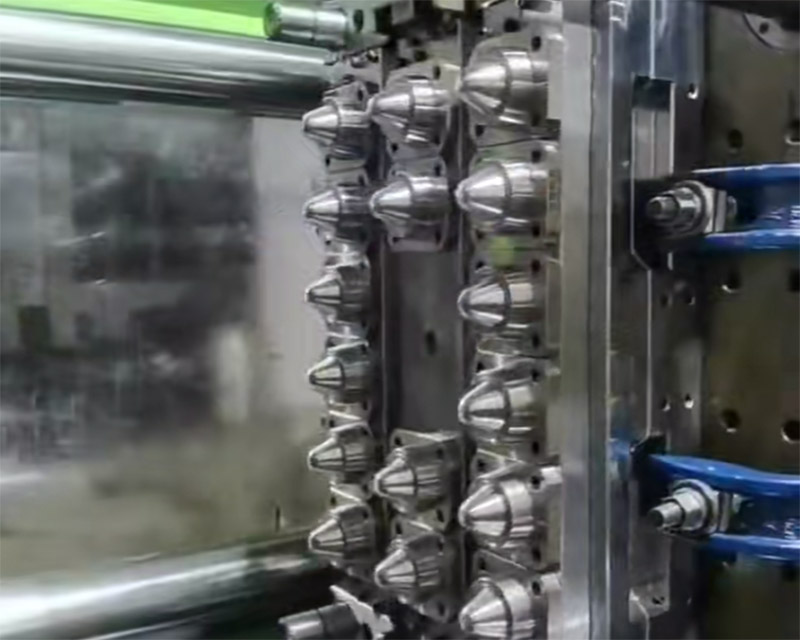

Mold Manufacturing Completed: Testing Now In Progress for 48g Wide-Mouth Preform

Lei Zhen Mold, a leading manufacturer of high-precision injection molds for the packaging industry, i...

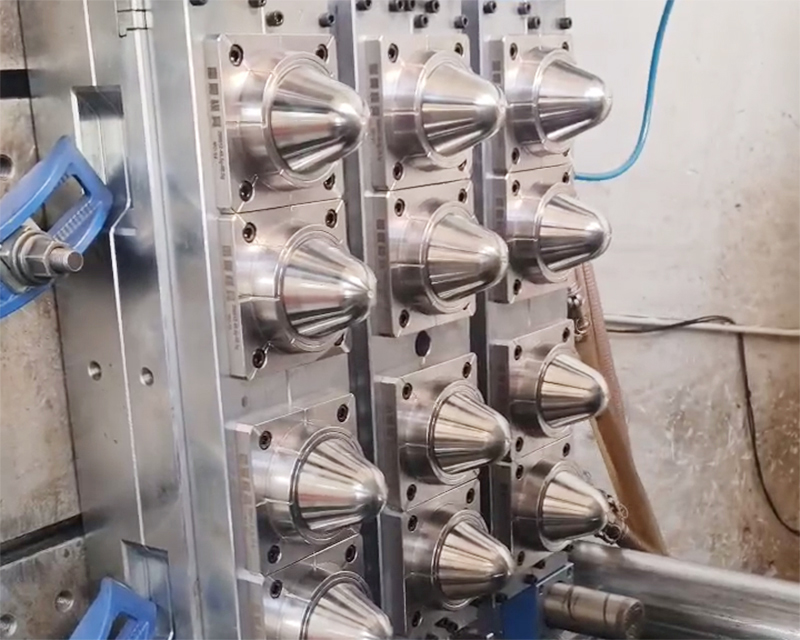

16-cavity wide-mouth preform mold

16 cavity pet preform mold for plastic packing. Shop our injection molding machines and PET preform m...

165 caliber 1900g ocean float bottle PET preform mould

The 165 caliber 1900g ocean float bottle PET preform mold is engineered for manufacturing large, buoy...

High Quality 720g 5 Gallon Pet Plastic Preform for Water Bottles

19 Liter 5 Gallon Plastic Water Bottle Making Machine 608g 720g Pet Preform Stretch Blow Molding Mach...

16 Cavity Customised PET Preform Mould For Jar Bottles

Our capabilities is offering the cavity number of PET molds ranges between 4 to 72. To provide custom...

Hot Runner Pet Jar Preform Mould Manufacturer

wide neck jar preform mold manufacturers, designed for precision and efficiency in bottle production...

48 cavity 85gm 45mm Husky Preform Mould

48 cavity preform mould, year 2010. Built for: HyPET. Used on: Husky HyPET 400. Shots used: 67,869. P...

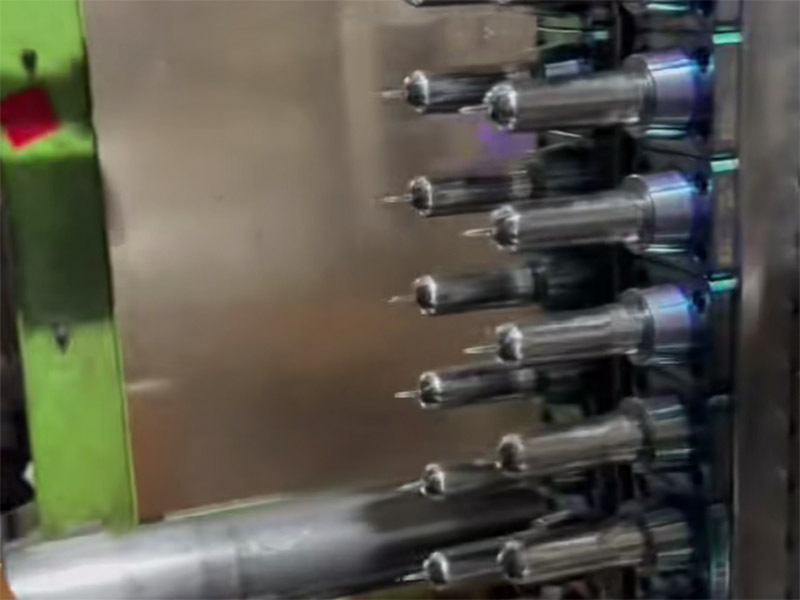

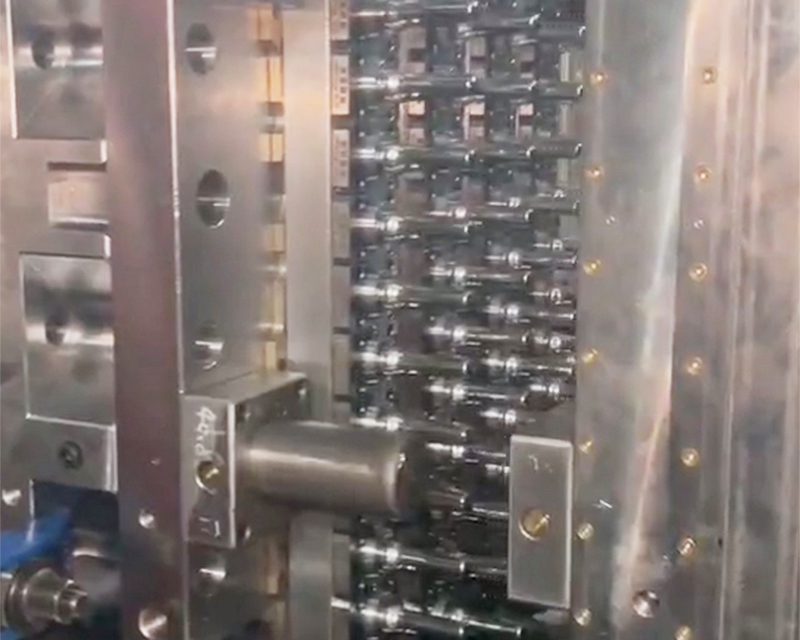

48 Cavities PET Preform Molds with Shut-Off Nozzle

Get high-quality and durable 48 Cavity PET Preform Moulds from our factory. We specialize in manufact...

PET Preform 48 Cavity Mould - Customizable & Durable

PET preform molds are an essential component in the manufacturing of PET preforms, which serve as the...

Wide Mouth Bottle Mold Manufacturing – Three Major Advantages

Our molds are CNC-machined with micron-level accuracy, ensuring consistent bottle dimensions, smooth finishes, and perfect sealing every time.

- Quality Control System

- Building Quality Industrial

Made from high-grade steel and advanced alloys, LEIZHEN molds withstand high-volume production without wear, reducing downtime and maintenance costs.

- Quality Control System

- Building Quality Industrial

Innovative cooling systems and streamlined designs enable faster cycle times, boosting output while maintaining top-tier quality.

- Quality Control System

- Building Quality Industrial

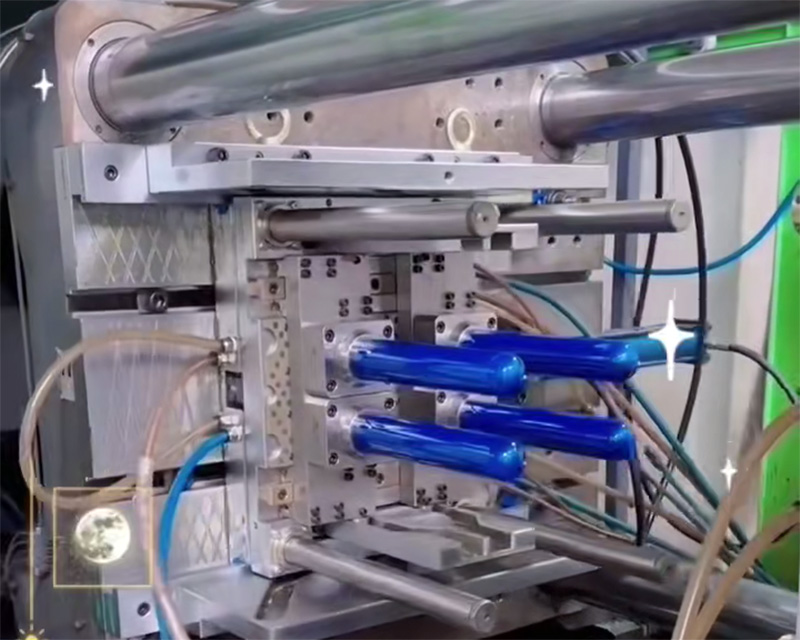

4 Major Processes of Preform Mold Manufacturing

Design & Engineering

CAD Modeling – Advanced 3D software designs the mold with exact dimensions, cooling channels, and ejection systems. Simulation Testing – Finite Element Analysis (FEA) ensures optimal material flow, cooling efficiency, and structural durability.

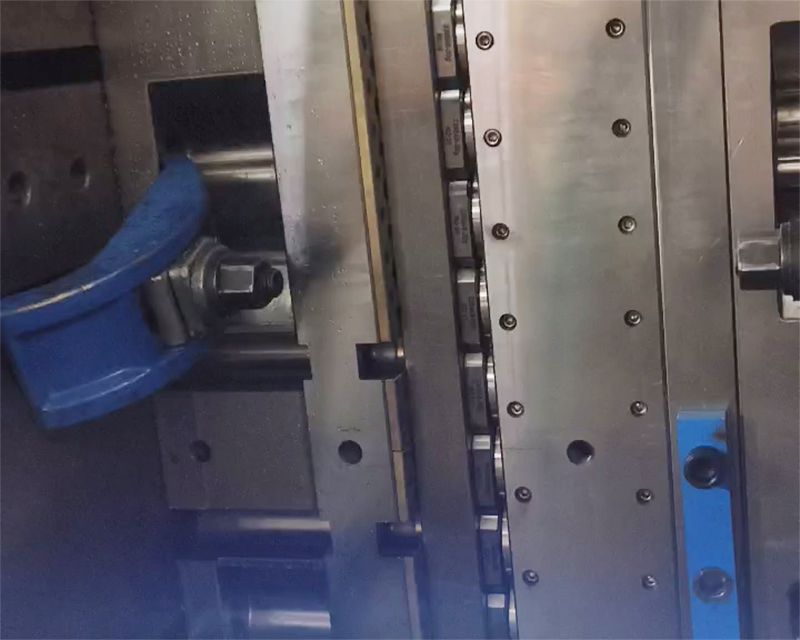

Precision Machining

CNMilling & Turning – High-speed CNC machines shape the mold cavities and cores with micron-level accuracy. EDM (Electrical Discharge Machining) – Used for intricate details and hardened steel components.

Heat Treatment & Surface Finishing

Hardening (Nitriding/Tempering) – Enhances wear resistance for long-lasting performance. Polishing & Texture Application – Ensures smooth preform ejection and desired surface finish (glossy/matte).

Assembly & Quality Testing

Component Fitting – Core inserts, cooling lines, and ejection systems are meticulously assembled. Trial Production & Inspection – Test runs verify dimensional accuracy, cycle efficiency, and defect-free preforms.

Have any Question?

If you are interested in our products, please leave your information and we will contact you.