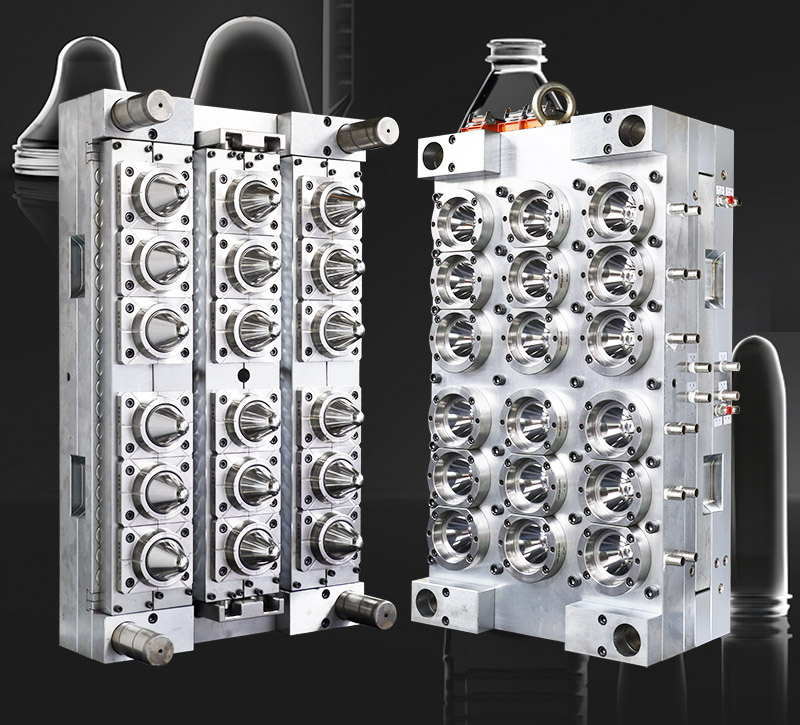

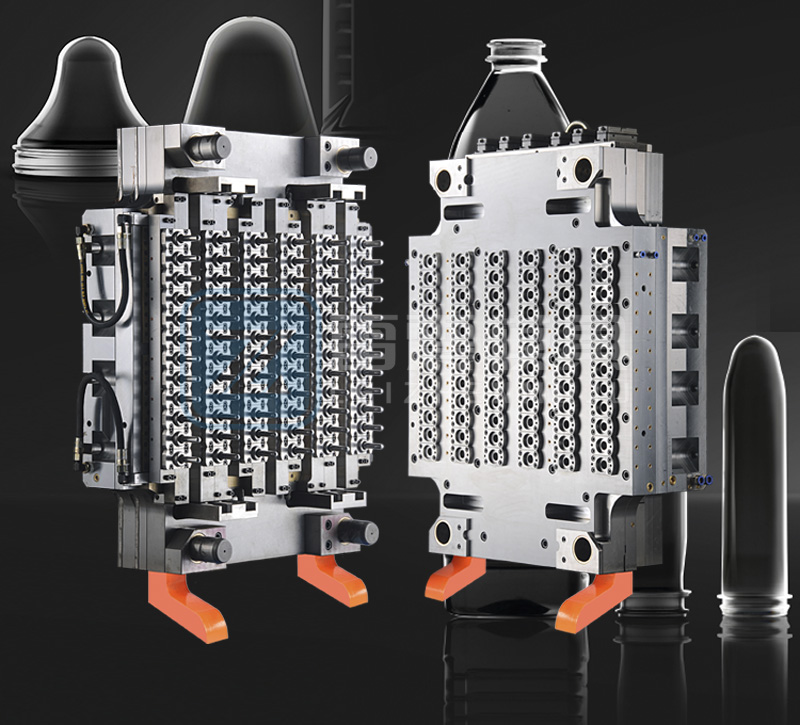

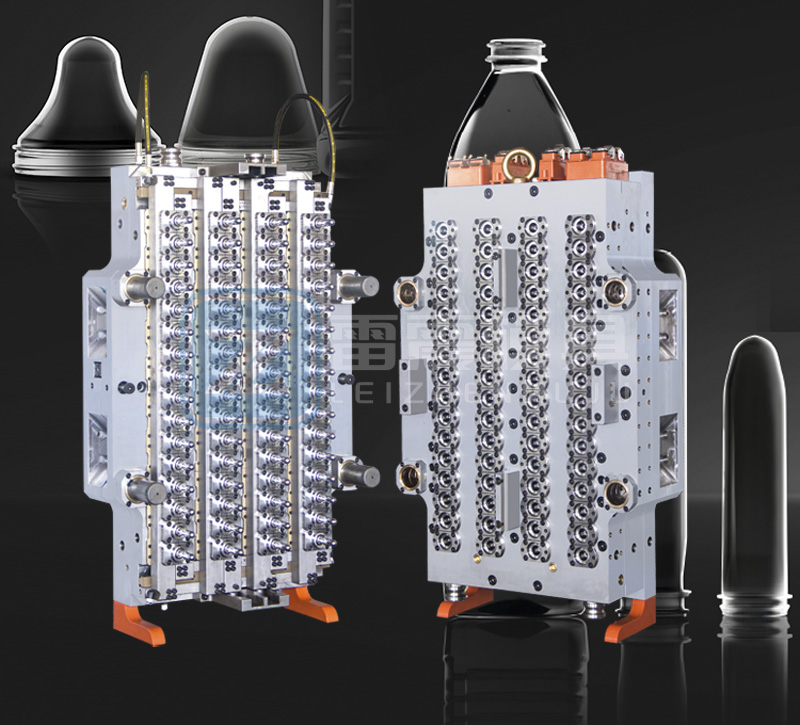

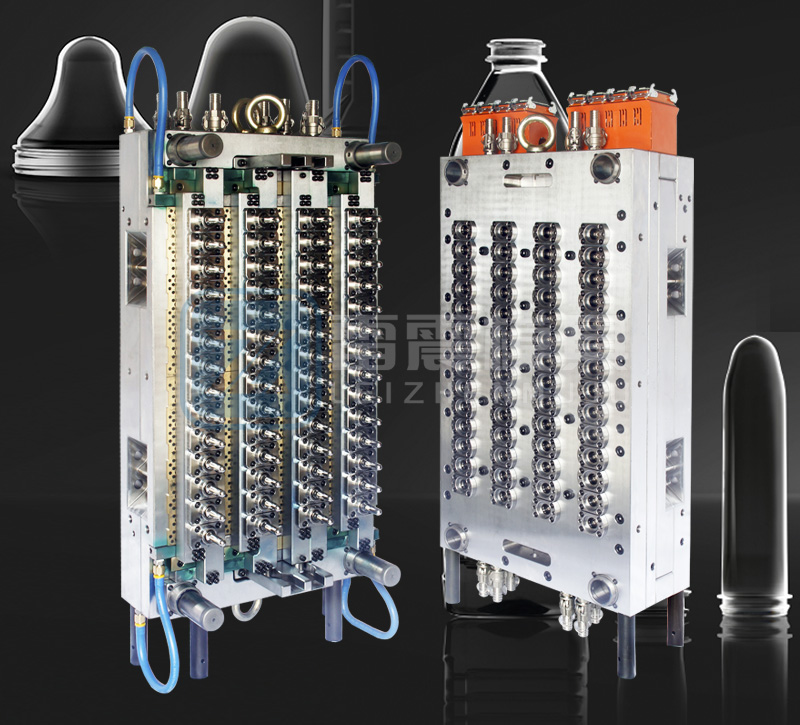

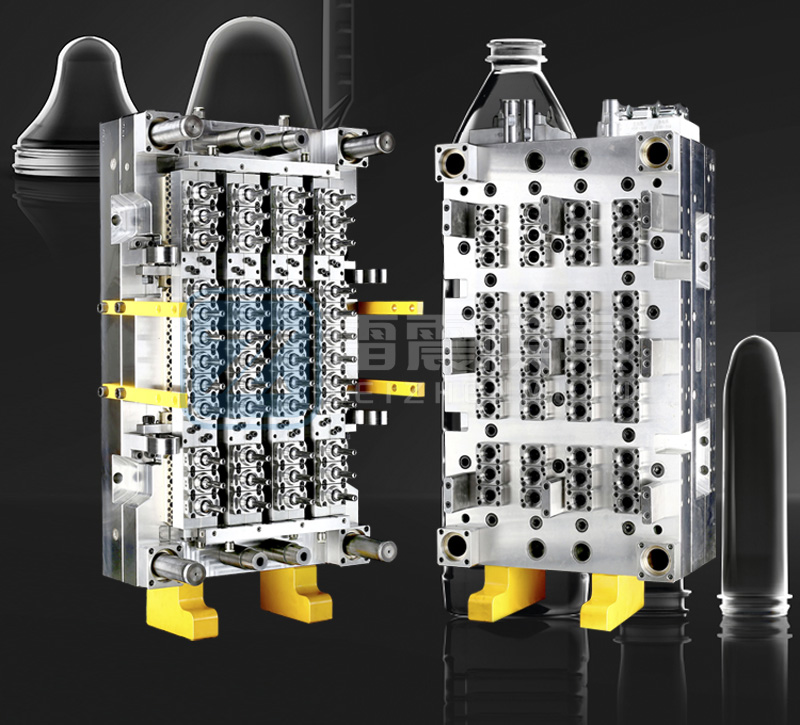

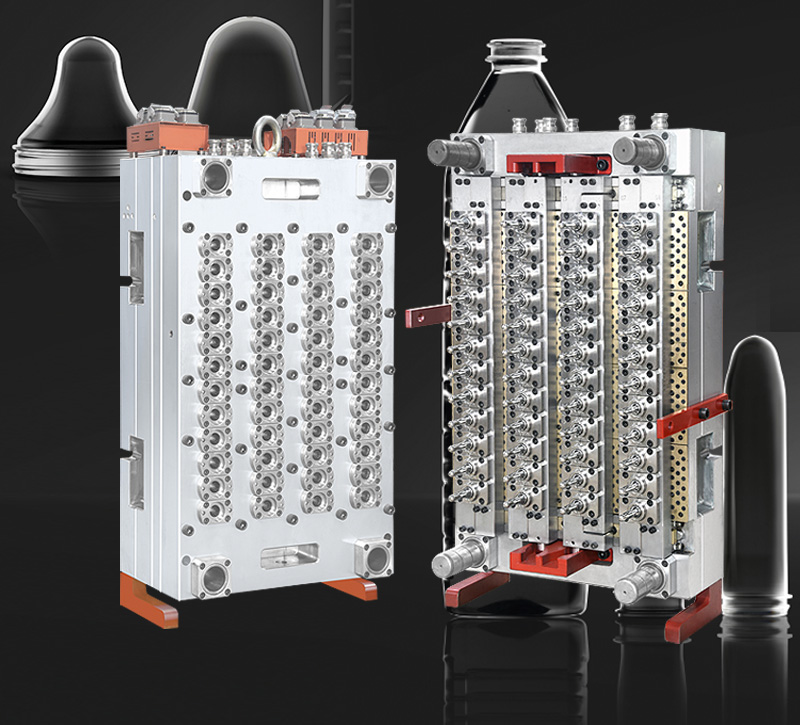

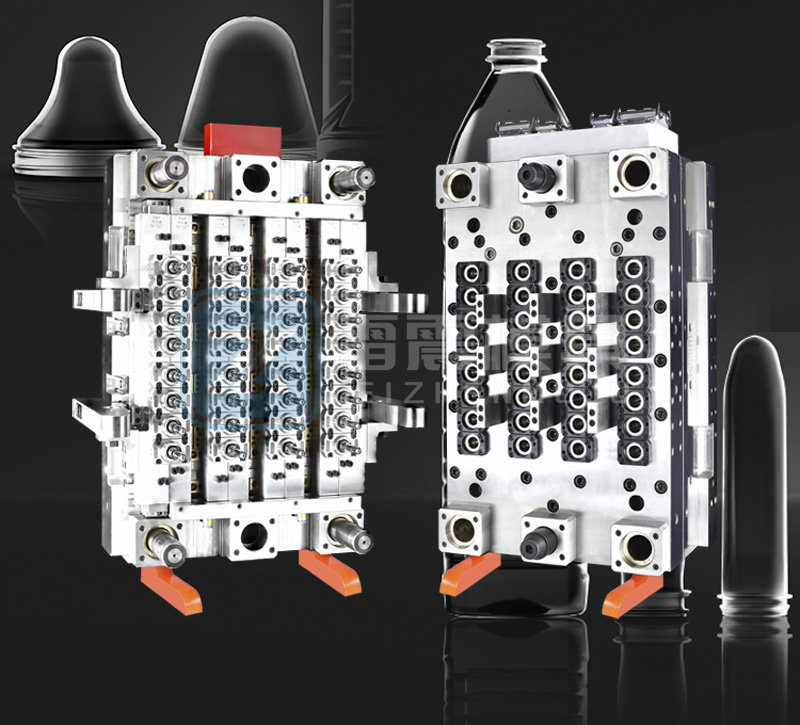

165 caliber 1900g ocean float bottle PET preform mould

Why Our Preform Molds Stand Out

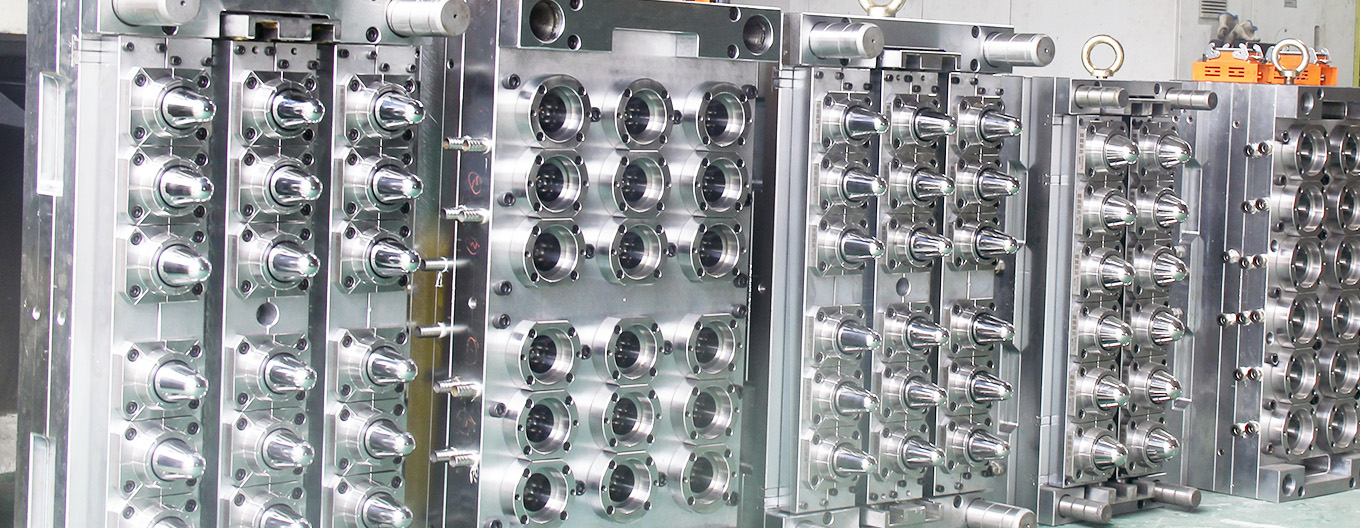

Our molds are meticulously designed, machined, and tested to eliminate defects and maximize efficiency. Key advantages include:

✅ Zero Defect Guarantee – Every mold undergoes rigorous testing before delivery, ensuring 100% molding rate with no rejects.

✅ Ultra-Durable Construction – Made from premium hardened steel with advanced heat treatment for extended service life.

✅ Optimized Cooling & Cycle Time – Precision-engineered cooling channels enable faster production without compromising quality.

✅ Customization Ready – Tailored to your specific preform design (neck finish, weight, wall thickness) for seamless integration into your production line.

Our Strict Mold Testing Process

Before any mold leaves our facility, it must pass three critical validation stages:

-

Trial Production Run – We mold sample preforms to verify dimensional accuracy and material distribution.

-

Performance Stress Test – The mold undergoes high-cycle testing to ensure stability under continuous operation.

-

Final Quality Inspection – Each preform is checked for:

-

Weight consistency

-

Wall thickness uniformity

-

Neck finish perfection

-

Only after 100% compliance do we approve the mold for delivery.

The LEIZHEN Advantage

-

Reduced Downtime – Our molds are built for longevity and easy maintenance, minimizing production interruptions.

-

Energy Efficiency – Optimized cooling systems lower energy consumption, cutting operational costs.

-

Global Reliability – Trusted by PET manufacturers worldwide for consistent, high-output performance.

Conclusion

When you choose LEIZHEN preform molds, you’re not just buying a tool—you’re investing in unmatched precision, reliability, and efficiency.

Ready to upgrade your production? Contact us today for a mold that delivers perfection, every time.

The 165 caliber 1900g ocean float bottle PET preform mold is engineered for manufacturing large, buoyant PET preforms used in marine floats, fishing gear, and industrial floating devices. Designed for durability and precision, this mold ensures consistent wall thickness, optimal material distribution, and high-performance blow molding compatibility.

Key Features

✔ Precision Engineering for Large Preforms

165mm caliber & 1900g weight – Ideal for heavy-duty ocean float bottles and industrial applications.

High-cavity consistency – Ensures uniform preforms for stable blow molding performance.

✔ Durable & Long-Lasting Construction

High-grade alloy steel (P20, H13, or S136) – Resists wear and corrosion in harsh marine environments.

Hardened & polished surfaces – Reduces friction and extends mold lifespan.

✔ Optimized for PET Blow Molding

Perfect stretch ratio – Ensures ideal material distribution for high buoyancy and impact resistance.

Compatible with high-capacity injection molding machines (1,500+ ton clamping force recommended).

✔ Efficient Cooling System

Conformal cooling channels – Accelerates cycle time for faster production.

Uniform cooling – Prevents defects like warping or sink marks.

✔ Customizable Design Options

Neck finishes (PCO, BPF, or custom threads) – Adaptable for different sealing requirements.

Multiple cavity configurations (1+1, 1+2, etc.) – Boosts production efficiency.

In the competitive world of PET packaging, quality begins at the mold. At LEIZHEN, we engineer high-precision preform molds that guarantee 100% molding success—ensuring every preform meets exact specifications for flawless bottle production.

Leizhen mould