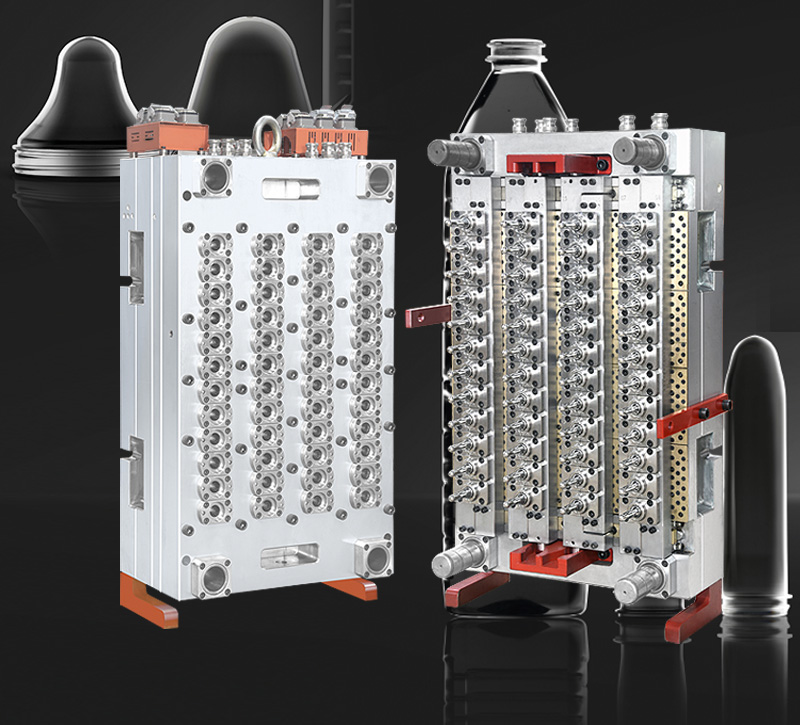

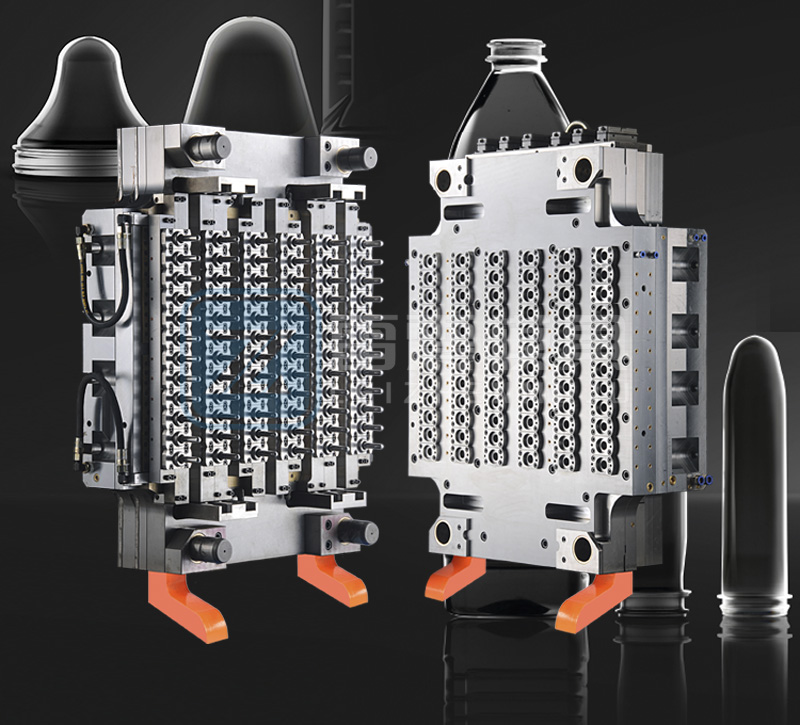

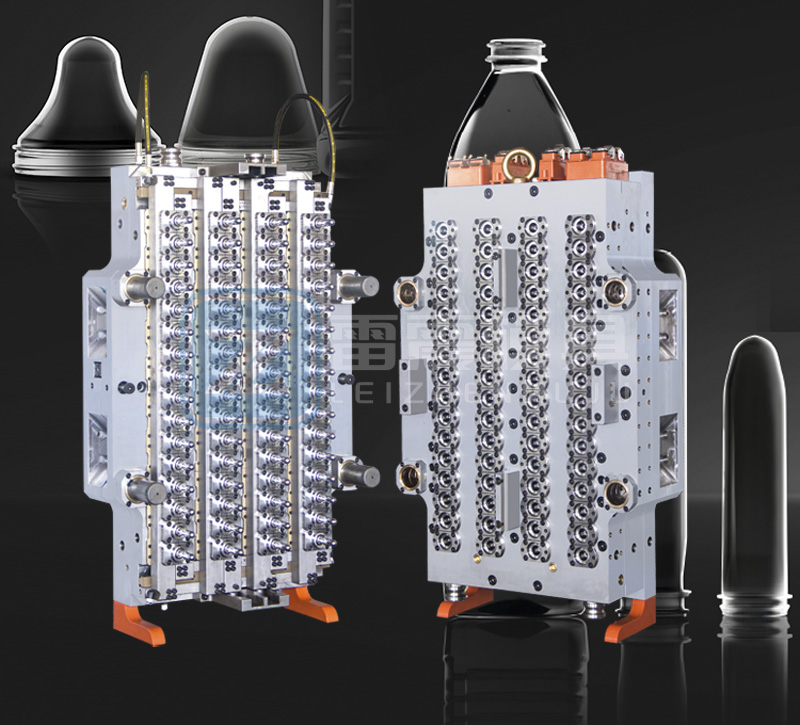

28mm Water Preform Mold 48 Cavity PET Mould

Is a professional mould manufacturer PET preform, is located in Taizhou, China.with more than ten years experience on making kinds of bottle cap mould and PET preform mould.

Product Name:28 mm 1810 PET Preform Mould | ||||

Neck Size: | 28mm 1810 | |||

Weight: | 18g | |||

Cavities Numbers: | 48 cavities | |||

Runner : | Hot runner(with following famous parts)

Heating ring : Gamany HOTSET Insulated pad : U.S. Dupont Needle : SKD-61 Japan Punch Copper Nozzle: U.S. bete(Copper with chroming coated) Nozzle holder : Japan SKD-61 (for hold the nozzle) | |||

Injection Gate : | Pin Vavle Gate | |||

Ejection Way: | Slider and Push plate | |||

Cycle time: | 23-25s | |||

Shot life: | 3-5 millions (at least) | |||

Material of Core/Cavity/Thread: | S136 | |||

Material of Holder/Base: | P20 | |||

Used for: | PET 500ml water bottle,cartonated drinking bottle

See follow bottle samples | |||

High-Quality Construction: This 28mm PCO 1810 18g Water PET preform mould is crafted from durable S136 steel and P20 holder/base material, ensuring a long-lasting and reliable performance.

Efficient Production: With 48 cavities, this mould enables mass production of 48 water bottles in a single cycle, significantly increasing production efficiency and meeting the demands of high-volume manufacturing.

Customized Design: This mould is designed for the production of 28mm water bottle preforms, suitable for use in various industries, including the manufacture of carbonated drinking PET bottles.

Long Service Life: The mould is expected to last for at least 5 million cycles, minimizing downtime and maintenance, and reducing overall production costs.

User-Friendly Design: The mould features a hot runner system and a slider and push tube ejection mechanism, making it easy to operate and maintain, reducing the risk of user error and ensuring smooth production processes.

Place of origin | TAIZHOU, CHINA |

Brand name | LEIZHEN MOULD |

Model | Plastic injection mould |

Product | OEM customized Preform |

Product material | PET |

Runner | Hot runner, Air seal, Needle valve |

Cavity number | 4,8,12,16,24,32 etc... |

Surface Treatment | Hardening treatment, Nitriding treatment, electroplating treatment |

Steel material | core and cavity is S136/FS636, mould base is P20 |

Spare parts | 1set core/cavity for 8cavity, 2sets of core/cavity for 16cavity |

Mould lifetime | 1-5 million shots |

Delivery time | 45-60days |

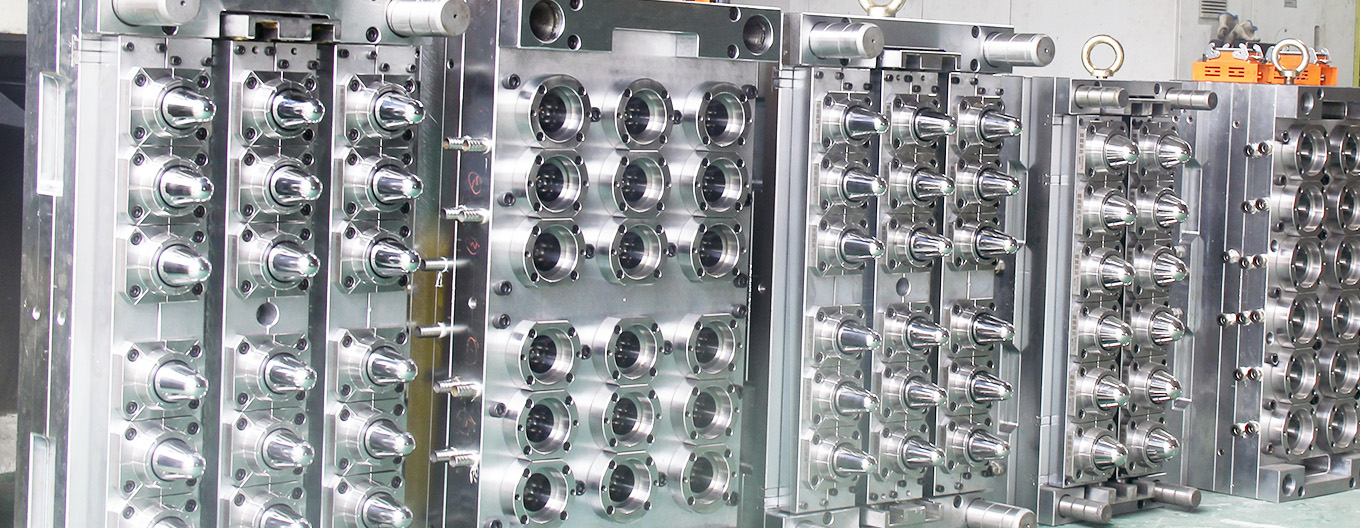

Leizhen’s Advantages in the Preform Mold Process: Precision, Innovation, and Reliability

In the competitive world of PET preform mold manufacturing, Leizhen has emerged as a trusted partner for brands and bottlers worldwide. Renowned for its engineering expertise, cutting-edge technology, and customer-centric approach, Leizhen delivers molds that optimize production efficiency, quality, and cost-effectiveness. Here’s an in-depth look at the advantages that set Leizhen apart in the preform mold industry:

Professional PET preform mold manufacturer | Helping efficient production and achieving perfect bottle shape

As an industry-leading PET preform mold manufacturer, we focus on providing high-precision, long-life, customized preform mold solutions for global beverage, food, daily chemical and pharmaceutical companies. From design to mass production, we use innovative technology and excellent quality to help you achieve a double breakthrough in production efficiency and product quality!

(Mold Cav Qty) | Neck Size) | Application |

18 cav | 48mm, 38mm,30/25,20/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, edible oil, medicine |

24 cav | 48mm,38mm,30/25,29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical, products, edible oil, medicine |

32 cav | 48mm,38mm,30/25,29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, edible oil, medicine |

48 cav | 48mm,38mm,30/25,29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, edible oil, medicine |

56 cav | 48mm, 38mm, 30/25, 29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, edible oil, medicine |

72 cav | 38mm, 30/25,29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, medicine |

96 cav | 38mm, 30/25, 29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, medicine |

112 cav | 30/25, 29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, edible oil, medicine |

128 cav | 30/25, 29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, edible oil, medicine |

144 cav | 30/25, 29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, edible oil, medicine |

176 cav | 30/25, 29/25, PCO1881, PCO1810 | Water, Juice, CSD, Daily chemical products, edible oil, medicine |

Uniform Preform Quality: Advanced flow simulation software balances the runner system, guaranteeing consistent filling and wall thickness across all cavities.

Tight Tolerances: Precision machining (±0.005mm) ensures compliance with international standards (e.g., PCO 1881, BPF) for neck finishes and thread designs.

Durability: Molds are crafted from premium steel (H13, S136, or 420 stainless steel) with heat treatment (HRC 48–52) to withstand millions of cycles.

Conformal Cooling Channels: 3D-printed or machined cooling channels follow the contour of the preform, reducing cycle times by up to 30% and minimizing warpage.

Hot Runner Systems: Partnerships with top brands like Yudo or INCOE ensure leak-free, energy-efficient melt delivery. Valve-gated systems enable clean gate cuts for lightweight preforms.

High-Speed Compatibility: Molds are optimized for machines with clamping forces up to 1,500 tons, achieving cycle times as low as 8–12 seconds for 20g preforms.

In-House Testing: Every mold undergoes trial runs on injection molding machines to validate cycle times, cooling efficiency, and preform dimensions.

ISO Certification: Compliance with ISO 9001 standards ensures traceability and accountability at every production stage.

Third-Party Inspections: Collaborations with global certification bodies verify compliance with FDA, EU, and other regional regulations for food-grade PET.

Competitive Pricing: Direct manufacturing in China reduces overhead costs, offering savings of 20–40% compared to Western suppliers.

Long Mold Lifespan: Durable materials and coatings (e.g., nitriding, DLC) extend mold life to 3+ million shots, lowering cost-per-preform.

| How to place an order for moulds? | |

| 1.R&D | We support customer R&D. Make the files or improve the design if you needed. |

| 2. Quotation Making | Mould Quotation will be finished in 1 day according to the information we get. |

| 3. Negotiation | The quality, price, material, delivery time, payment item, etc. |

| 4. Mould Design | 1-2days for product 3D/2D drawing design as per customer's design. Then in further make the mould 2D/3D design. |

| 5. Mould | 1. confirm the products and the mold design |

| 2. Mould material prepare | |

| 3. Rough machining(heat treatment on mold base and pre-harden on mold) | |

| 4. CNC/ Vacuum Hardening on mold main spare parts | |

| 5. finishing machining( JDPAINT, DEM.etc) | |

| 6. Dimension inspection | |

| 7. Ejector& runner& cooling & other device processes | |

| 8. Assemble mold | |

| 6. Mould Testing | When moulds are finished, we will test the mould and we will send samples to client. |

| 7. Sample confirmation | If the first sample is not satisfied by the customer when it is come out. We modify the mould until meet the customer’s satisfaction. |

| 8. Delivery | Delivery goods by sea or by air, according to customer’s requirement. |