PET Preform Mold & Pet Preform Hot Runner Molds In China

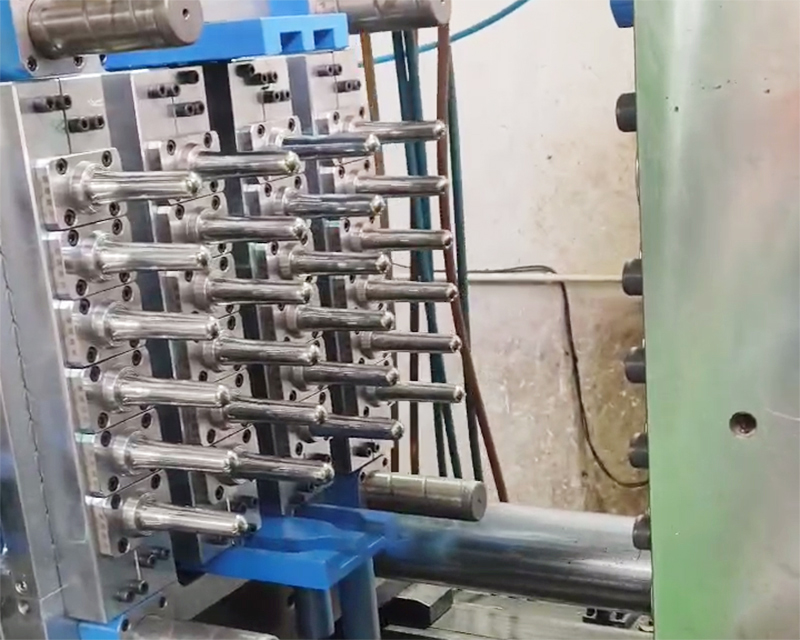

24 cavity 12 5g PET preform mold in P24 R65 13 2seconds

12.5g, 1881, 24-cavity, in P24-R65 PET preform injection molding system, 13.2seconds. For more soluti...

Wide Mouth Bottle Mold Manufacturing – Three Major Advantages

Our molds are CNC-machined with micron-level accuracy, ensuring consistent bottle dimensions, smooth finishes, and perfect sealing every time.

- Quality Control System

- Building Quality Industrial

Made from high-grade steel and advanced alloys, LEIZHEN molds withstand high-volume production without wear, reducing downtime and maintenance costs.

- Quality Control System

- Building Quality Industrial

Innovative cooling systems and streamlined designs enable faster cycle times, boosting output while maintaining top-tier quality.

- Quality Control System

- Building Quality Industrial

4 Major Processes of Preform Mold Manufacturing

Design & Engineering

CAD Modeling – Advanced 3D software designs the mold with exact dimensions, cooling channels, and ejection systems. Simulation Testing – Finite Element Analysis (FEA) ensures optimal material flow, cooling efficiency, and structural durability.

Precision Machining

CNMilling & Turning – High-speed CNC machines shape the mold cavities and cores with micron-level accuracy. EDM (Electrical Discharge Machining) – Used for intricate details and hardened steel components.

Heat Treatment & Surface Finishing

Hardening (Nitriding/Tempering) – Enhances wear resistance for long-lasting performance. Polishing & Texture Application – Ensures smooth preform ejection and desired surface finish (glossy/matte).

Assembly & Quality Testing

Component Fitting – Core inserts, cooling lines, and ejection systems are meticulously assembled. Trial Production & Inspection – Test runs verify dimensional accuracy, cycle efficiency, and defect-free preforms.

Have any Question?

If you are interested in our products, please leave your information and we will contact you.