The PET Preform Production Process: Essential Equipment & The Critical Role of Precision Molds

Producing high-quality PET preforms is a sophisticated process that transforms raw PET resin into the precise precursors of bottles and jars. The efficiency, consistency, and cost-effectiveness of this production line hinge on two core elements: advanced machinery and, fundamentally, a high-performance injection mold. At LEIZHEN, we specialize in crafting the molds that are the heart of this process. This article outlines the essential equipment for PET preform production and explains why the mold is the most critical investment for success.

The PET Preform Production Line: Key Equipment

A modern preform injection molding system is an integrated setup of several key components:

PET Resin Drying System: PET is highly hygroscopic. A dedicated dehumidifying dryer is essential to remove moisture from the resin before processing, preventing hydrolytic degradation that weakens the final preform.

Injection Molding Machine: A robust, high-precision injection machine is the core of the line. For preforms, machines require:

High Clamping Force: To withstand injection pressure into multi-cavity molds.

Reciprocating Screw: For consistent melting, mixing, and metering of PET.

Accurate Shot Control: To ensure identical preform weight and wall distribution.

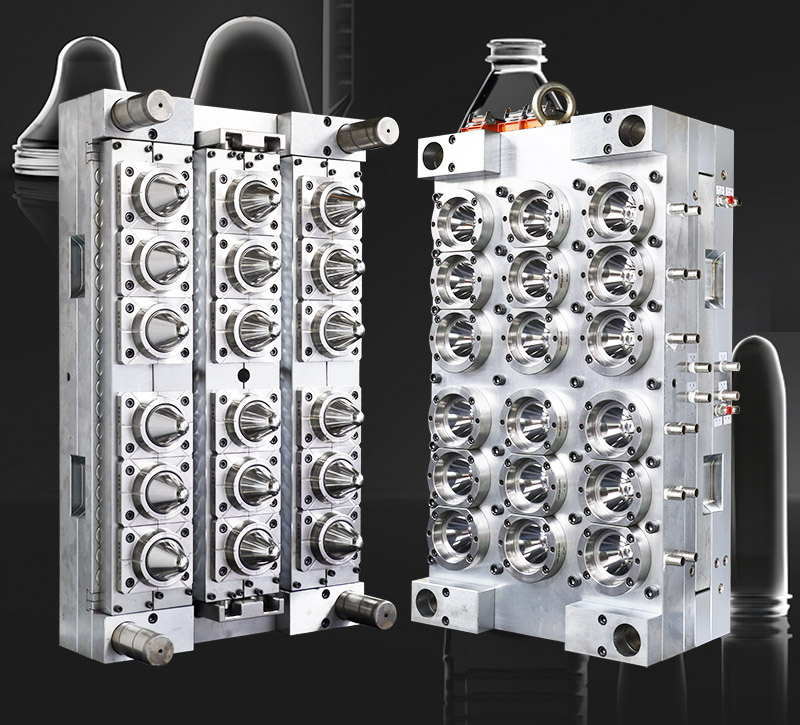

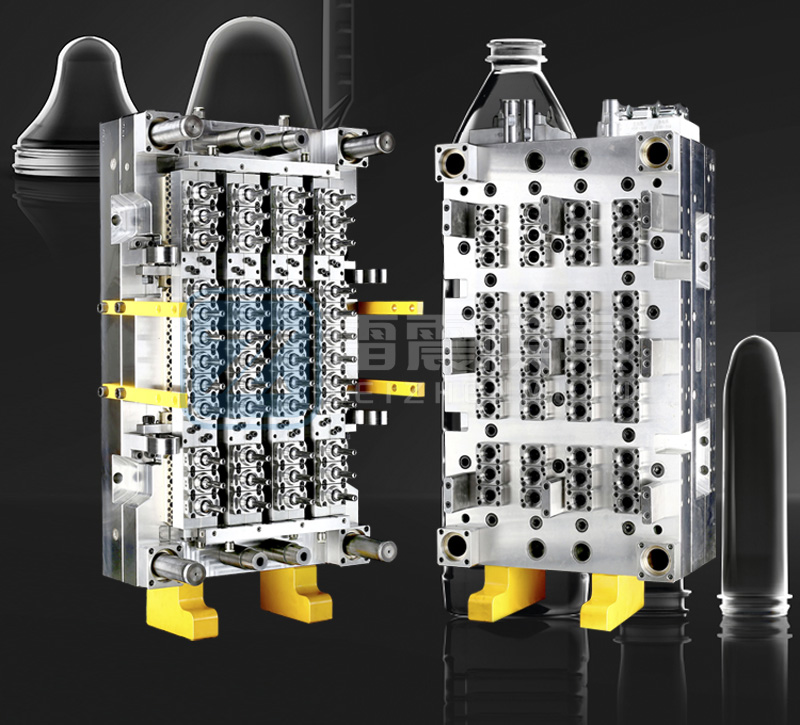

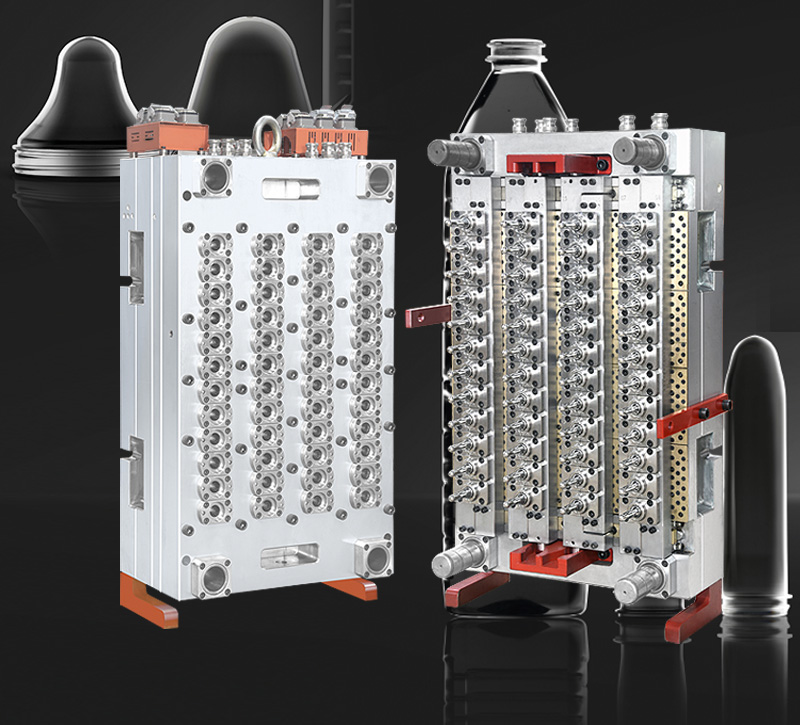

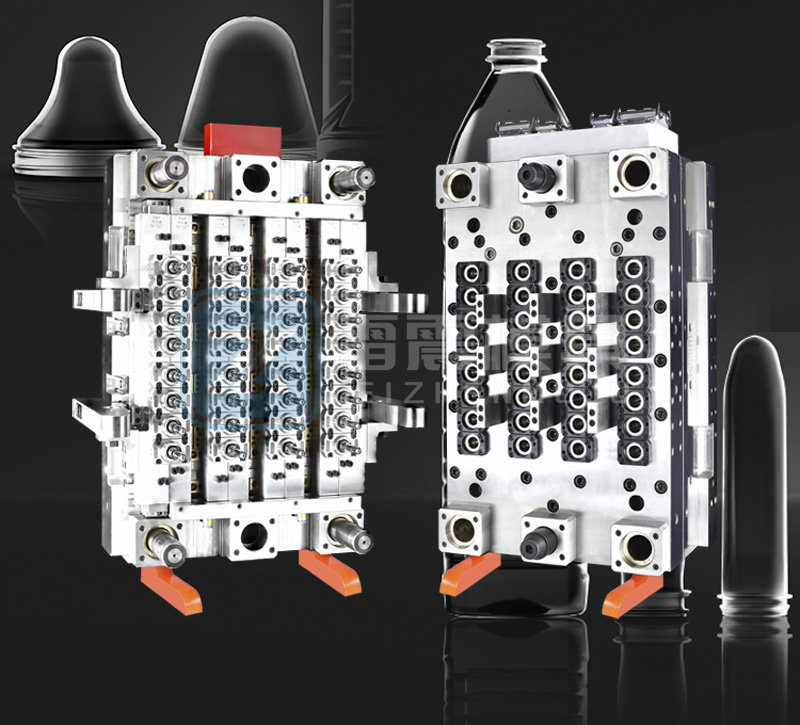

The Hot Runner Mold System: This is not just "equipment" but the custom-engineered centerpiece. It includes:

The Mold (Core & Cavity): The precision tool that defines the preform's shape, threads, and finish.

Hot Runner Manifold: Distributes molten PET to each cavity without cold sprues, reducing waste.

Temperature Controllers: Precisely manage the heat for both the hot runner and mold cooling circuits.

Take-Out & Handling Robotics: Automated robots gently remove preforms from the mold and transfer them to the cooling conveyor, ensuring consistency and preventing damage.

Cooling & Conveying System: A controlled cooling conveyor allows the preforms to anneal and stabilize their internal structure before packaging or downstream blowing.

Why Your Choice of Mold Manufacturer Defines Production Success

While all equipment is important, the mold is the defining factor for quality, efficiency, and profitability. Here is how LEIZHEN’s mold manufacturing expertise translates directly to your production advantage:

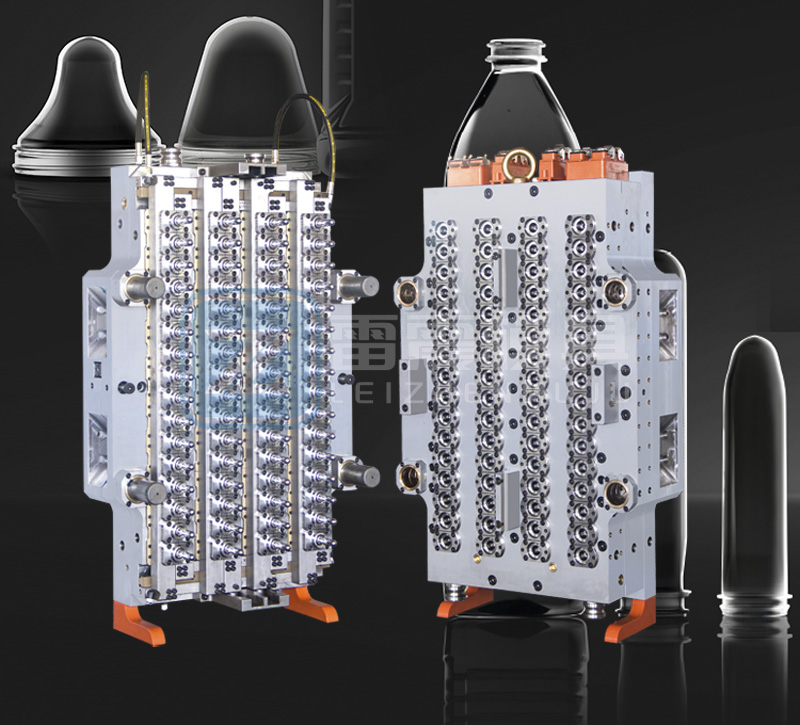

1. Unmatched Precision for Superior Preform Quality

Our

molds are engineered and machined to micron-level tolerances. This

precision ensures every preform cavity produces an identical part with

perfect neck finish (critical for capping), consistent wall thickness,

and optimal material distribution. This results in bottles with

excellent clarity, top-load strength, and barrier properties.

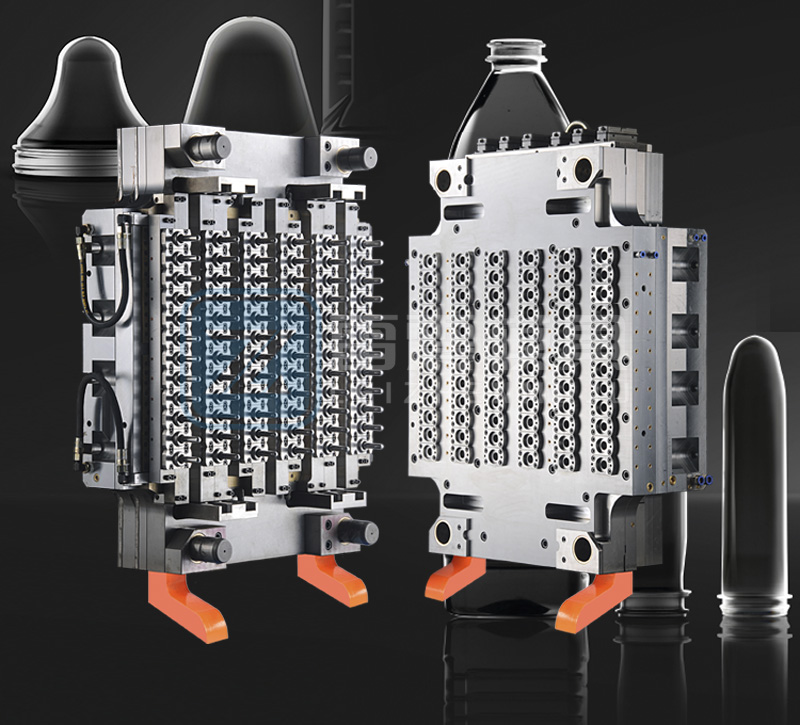

2. Advanced Cooling Technology for Maximum Output

Cycle time is the primary driver of production capacity. LEIZHEN designs and manufactures molds with optimized conformal cooling channels.

These channels follow the contour of the preform shape, enabling rapid

and uniform heat extraction. This proprietary approach significantly

reduces cycle times, directly increasing your output and ROI.

3. Uncompromising Durability for Lower Cost-Per-Part

We

construct our molds from premium, through-hardened steels (like H13)

and apply specialized surface treatments for critical components. This

combat wear, corrosion, and the abrasive nature of PET, extending mold

life for tens of millions of cycles. Our durable molds minimize

maintenance downtime and spare part costs, giving you the lowest

possible cost-per-preform.

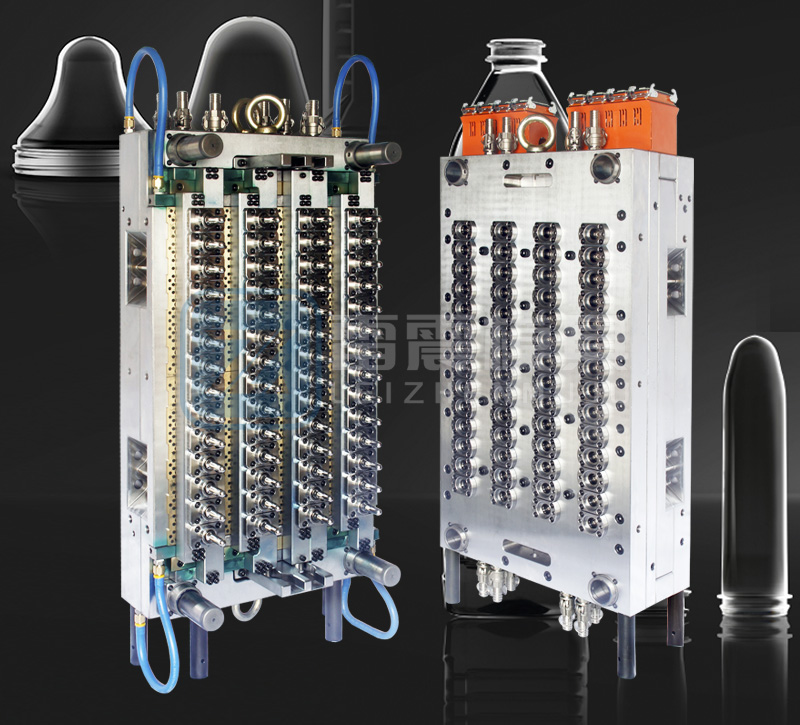

4. Expertise in Complex Designs, Especially Wide-Mouth

Producing

flawless preforms for jars and wide-mouth containers presents unique

challenges in material flow and cooling. LEIZHEN has deep expertise in

designing for these applications. We engineer solutions for uniform

filling of thicker sections and perfect sealing surfaces, ensuring your

jars perform flawlessly on filling and capping lines.

5. Seamless Integration & Total Support

A

LEIZHEN mold is designed for reliable performance within your entire

system. We ensure seamless integration with leading hot runner brands

and provide comprehensive process parameters. Our partnership includes

ongoing technical support, ensuring your production runs smoothly and

efficiently for years to come.

Conclusion: Partner with the Heart of Your Process

Investing in a LEIZHEN mold is an investment in the foundation of your preform production. We don't just build a tool; we deliver a precision-engineered system for quality, speed, and long-term reliability.

Optimize your PET preform production from the core. Contact LEIZHEN today to discuss how our superior mold technology can elevate your output and product quality.