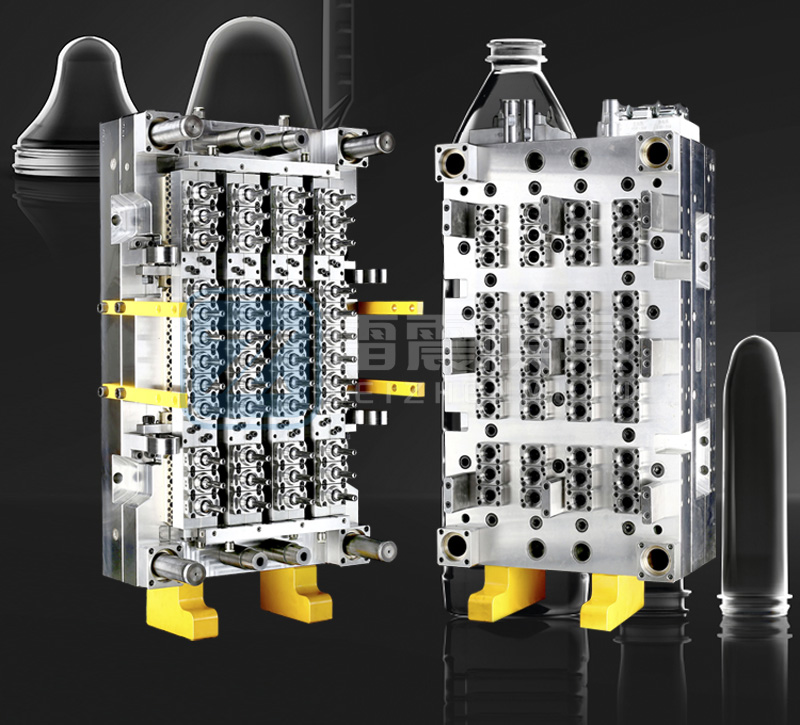

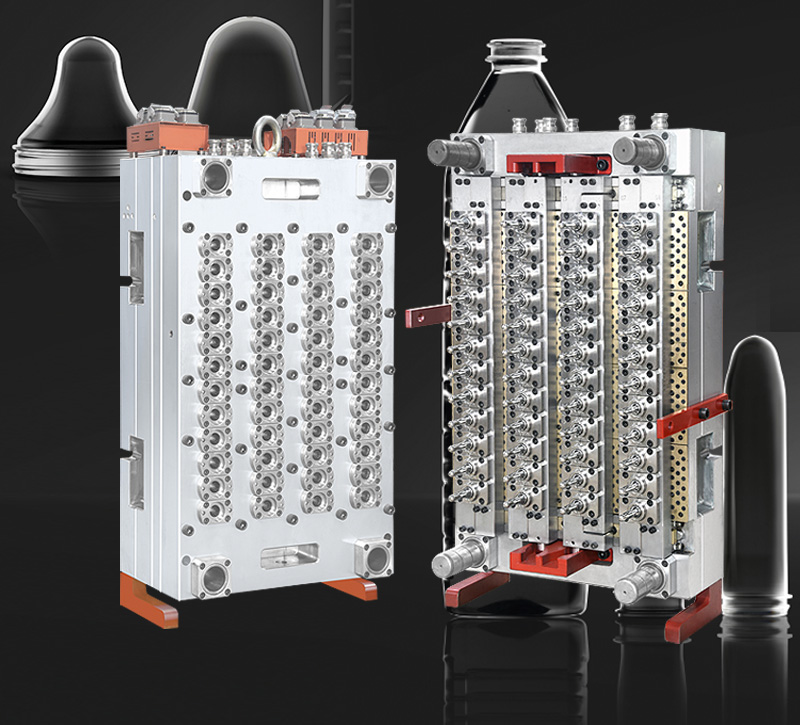

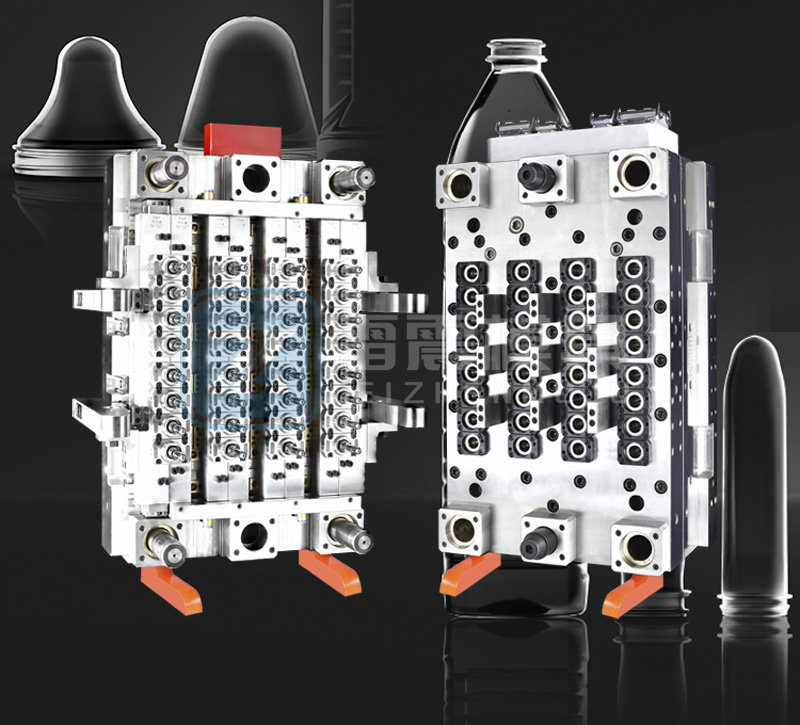

The Precision Process Behind LEIZHEN's PET Preform Molds

At LEIZHEN, we believe that excellence in manufacturing is not an accident—it's a meticulously engineered process. As specialists in wide-mouth PET preform molds, we have refined a manufacturing workflow that guarantees precision, durability, and performance. This article unveils the key stages of our mold-making process and explains how each step contributes to our superior end product.

Our Step-by-Step Manufacturing Workflow

1. Collaborative Design & DFM Analysis

The

journey begins with your concept. Our engineers work alongside your

team to translate packaging requirements into a functional mold design.

Using advanced 3D CAD software, we create detailed models. Crucially, we

perform a thorough Design for Manufacturability (DFM) analysis specific to wide-mouth applications. This stage focuses on

optimizing gate design, cooling channels, and venting to prevent defects

and ensure efficient material flow for thicker preform walls, setting

the foundation for a high-yield production mold.

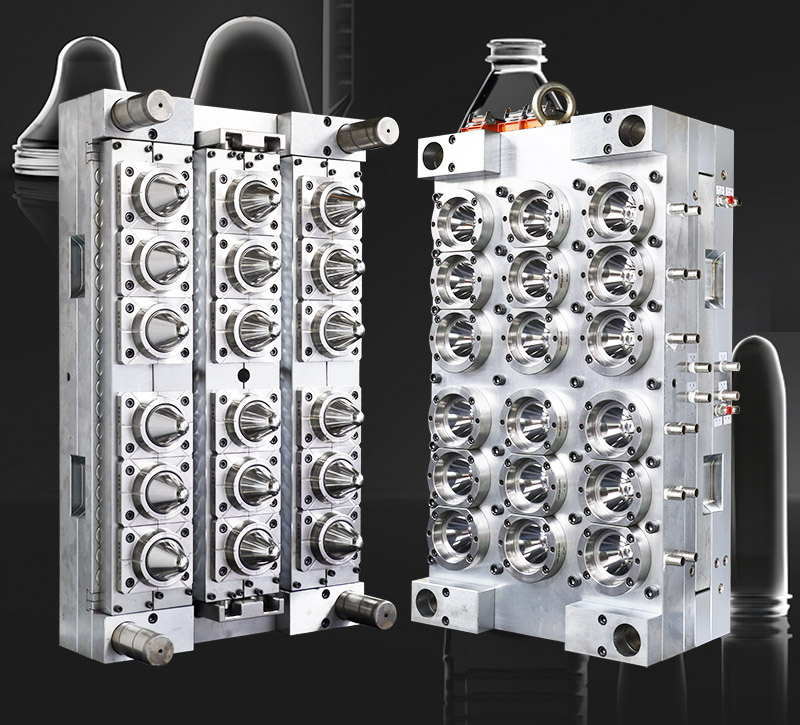

2. Precision Machining of Core & Cavity

This

is where our craftsmanship shines. The mold design is transferred to

our state-of-the-art CNC machining centers. We use premium hardened

steels (like H13) to mill the core and cavity blocks with micron-level

accuracy. For complex geometries and critical neck finish details of

wide-mouth preforms, we employ precision EDM (Electrical Discharge

Machining) processes. This ensures perfect thread forms and sealing

surfaces that are crucial for jar closures.

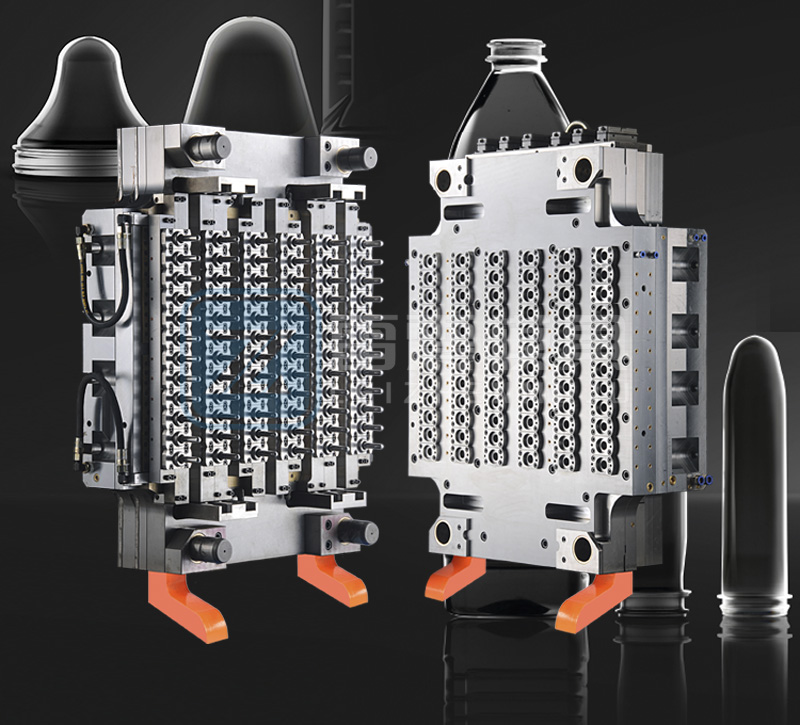

3. Advanced Cooling Channel Implementation

Cycle

time is king in injection molding. For wide-mouth preforms, which have

more material, efficient cooling is paramount. We drill and manufacture

conformal cooling channels that follow the contour of the preform shape

as closely as possible. This proprietary approach ensures rapid and

uniform heat extraction, dramatically reducing cycle times and improving

preform crystallinity and consistency.

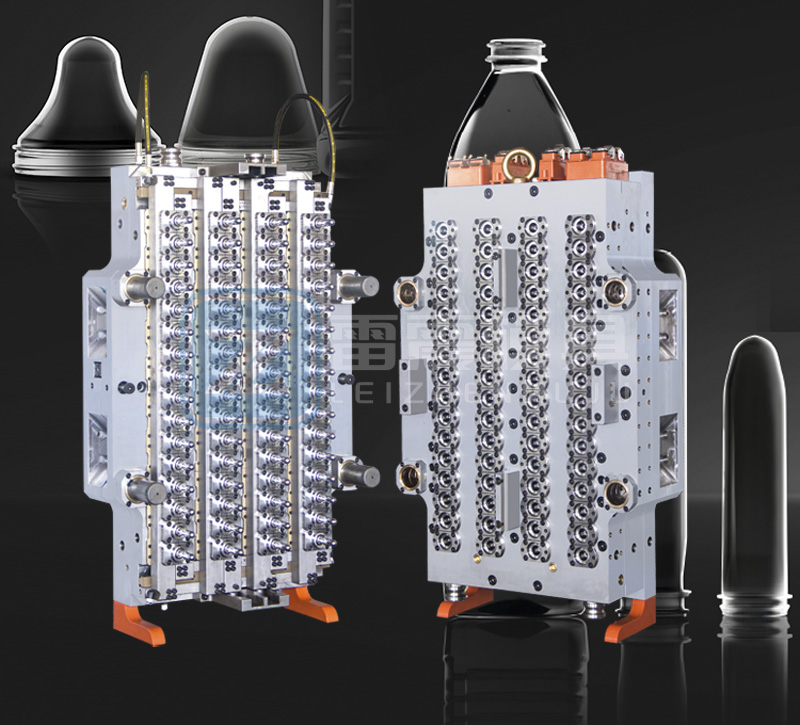

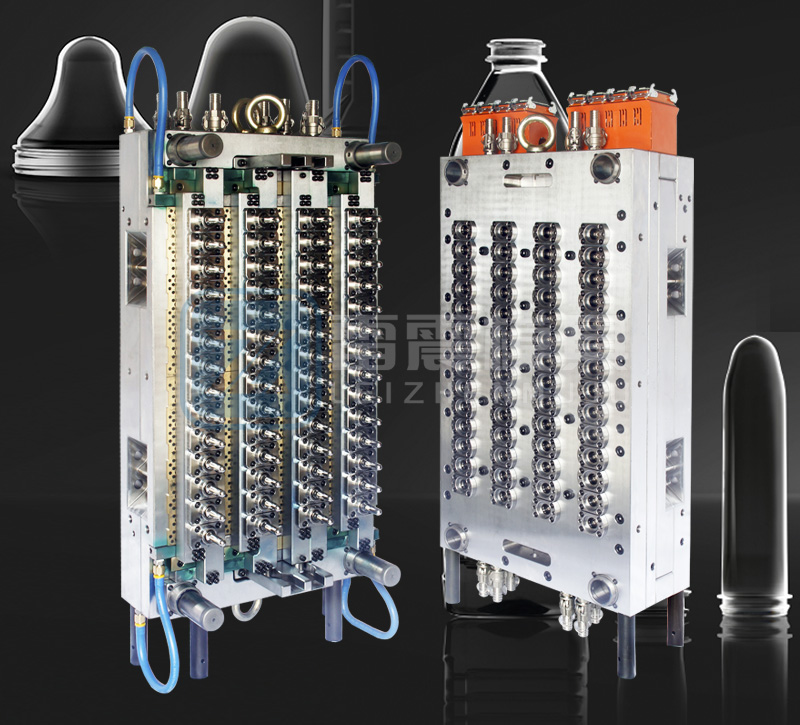

4. Meticulous Assembly & Integration

Every

component—from hot runner systems (selected from top brands like Yudo

or Mold Masters) to ejector pins and alignment guides—is assembled by

our master technicians. Each part is fitted, checked, and lubricated to

ensure flawless interaction. The integration of the hot runner system is

particularly critical for maintaining consistent melt temperature and

preventing material degradation in the larger gate areas of wide-mouth

designs.

5. Rigorous Testing & Validation

Before

shipment, every LEIZHEN mold undergoes a rigorous validation process.

We perform trial runs in our facility using production-equivalent

injection molding machines. We produce sample preforms, which are then

measured with CMMs, checked for weight consistency, and tested for

dimensions and wall thickness distribution. This allows us to fine-tune

the process and ensure the mold performs perfectly, meeting all

specifications before it reaches your production floor.

6. Comprehensive Documentation & Support

We

deliver more than a mold; we deliver a complete package. This includes

detailed technical drawings, maintenance manuals, and optimal process

parameters. Our support continues after delivery with troubleshooting

assistance and readily available spare parts, ensuring your production

longevity.

Why LEIZHEN's Process Delivers Superior Wide-Mouth Molds

Our entire manufacturing process is optimized for the unique challenges of wide-mouth jar preform molds:

Expertise in Thick-Wall Design: Our process prioritizes uniform filling and cooling for the heavier sections of wide-mouth preforms, preventing sinks and voids.

Focus on Critical Closure Features: The machining and polishing of thread and sealing surfaces are given extreme attention, ensuring leak-proof jars and easy capping.

Built for Durability: Using premium materials and precise heat treatment in our process results in molds that withstand the high injection pressures and abrasive nature of PET over millions of cycles.

Partner with LEIZHEN to benefit from a transparent, precise, and reliable mold manufacturing process designed for high-performance results.

Contact us today to start your project with a trusted leader in precision mold making.