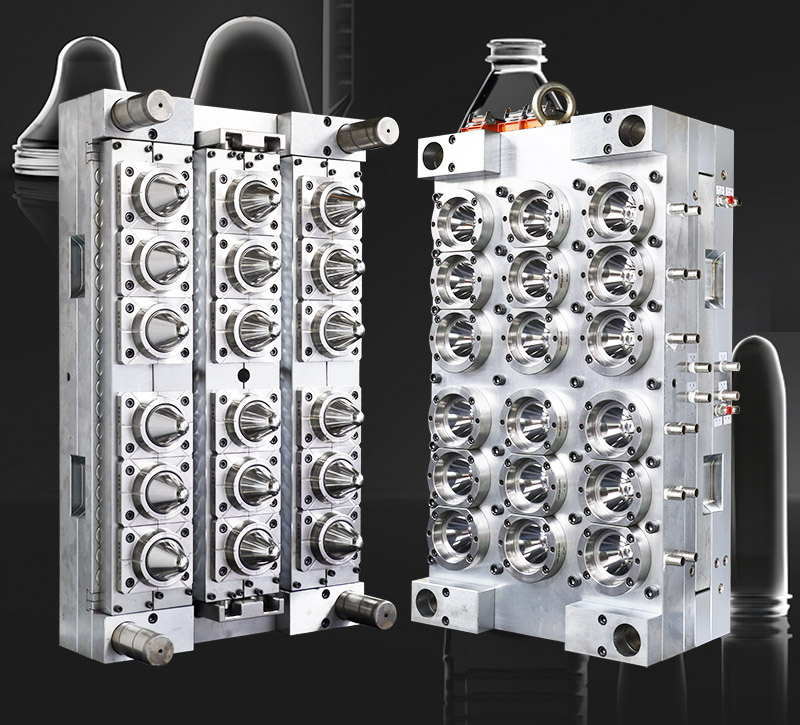

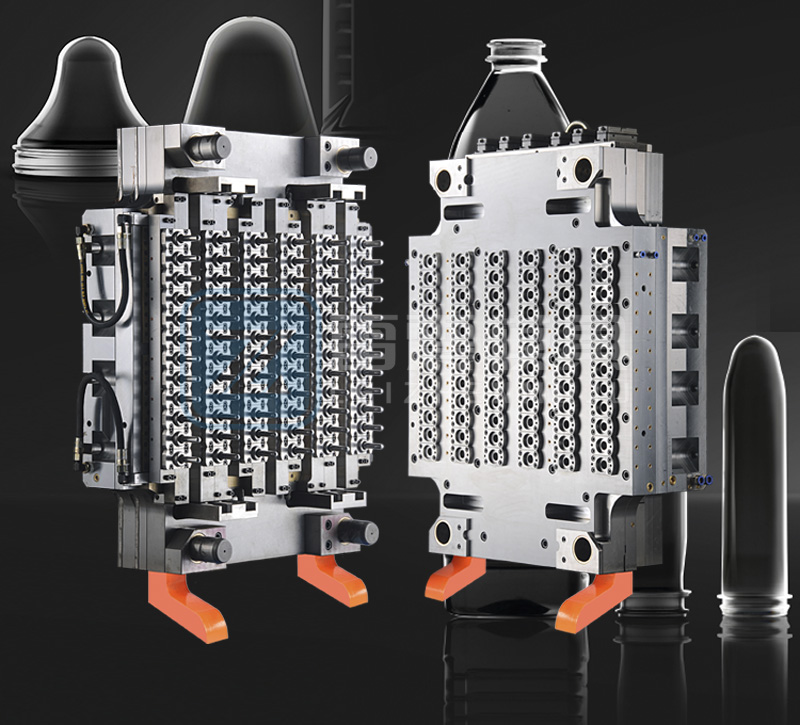

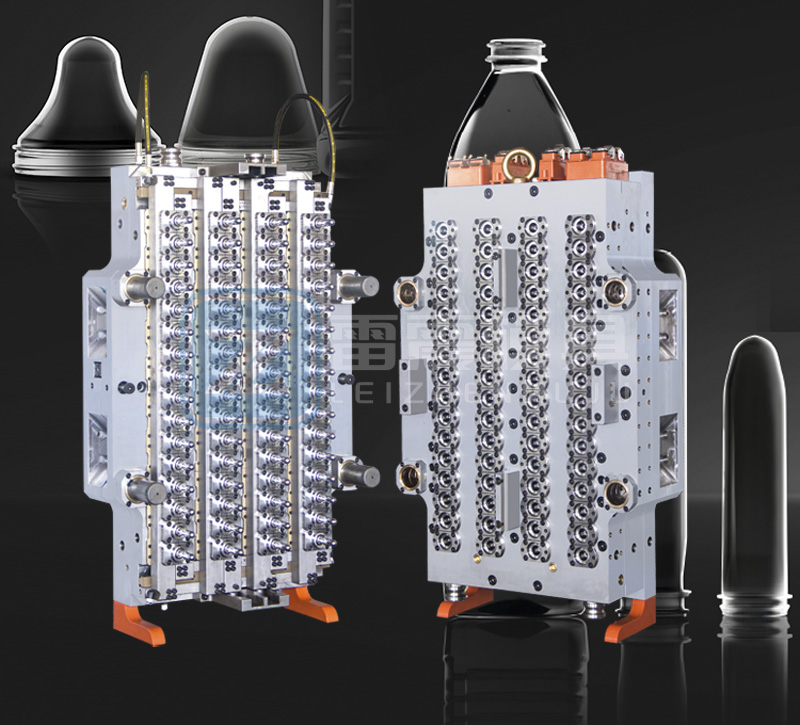

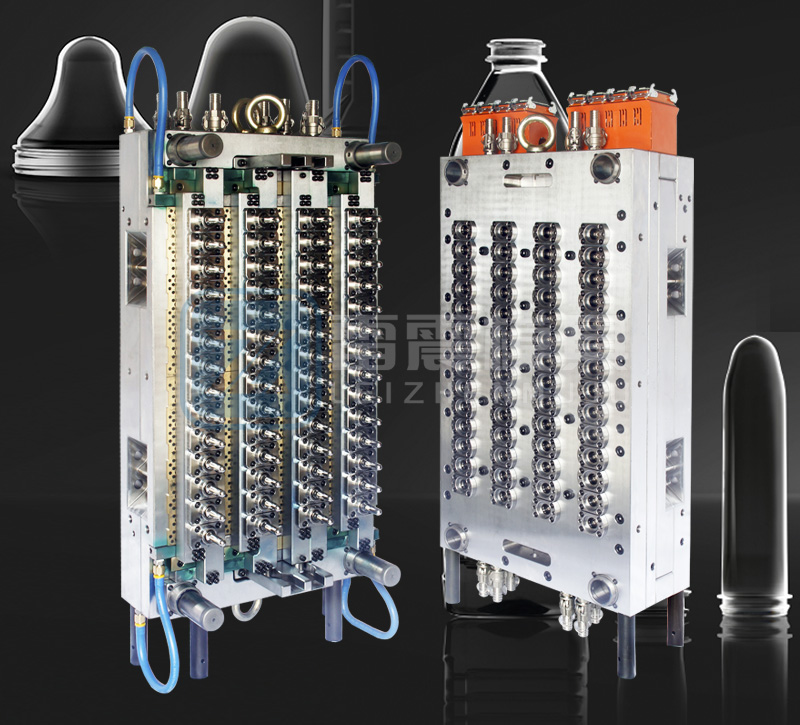

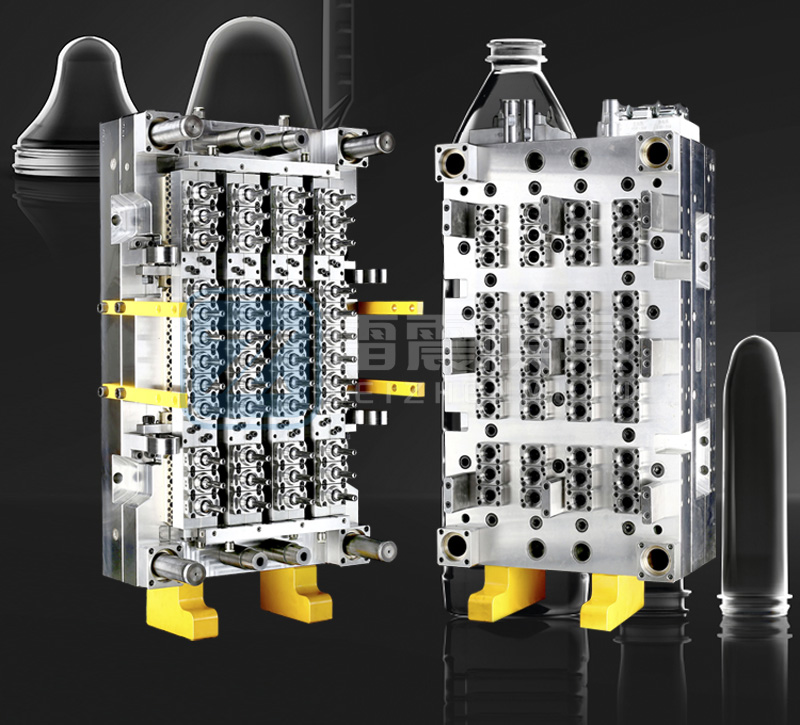

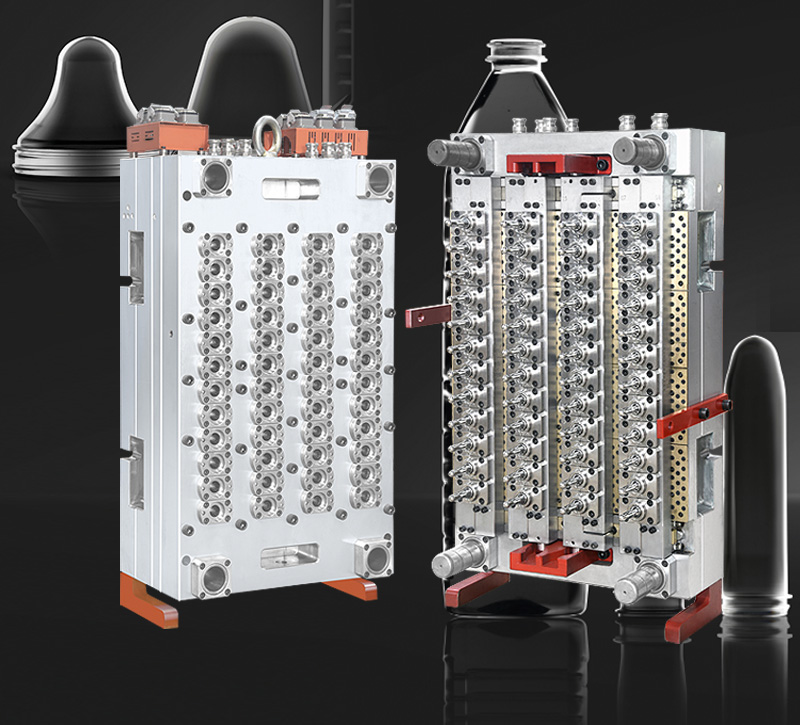

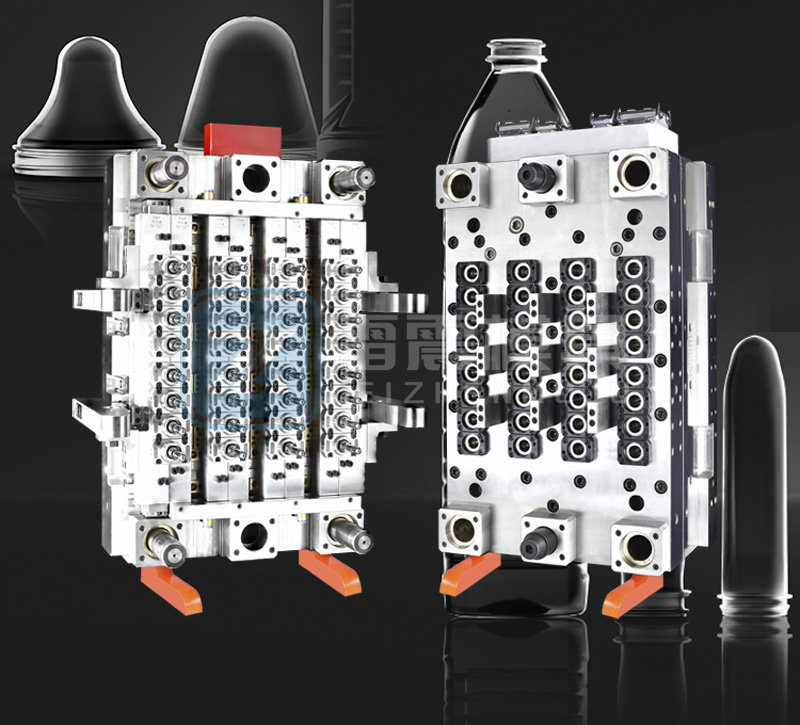

PET Bottle Preform Mold Manufacturing Process

The manufacturing of PET (Polyethylene Terephthalate) bottle preform molds involves a precise and highly skilled process that ensures the highest quality of molds for the production of PET bottles. PET bottle preforms are critical components in the bottle manufacturing process, serving as the initial shape before the bottles are blow-molded into their final form. Below is a detailed overview of the manufacturing process of PET bottle preform molds.

1. Mold Design and Engineering

The process begins with designing the mold, which requires extensive knowledge of the bottle's final specifications, such as size, thickness, and material. The mold design stage is crucial to ensure that the preforms will have the correct dimensions and strength for the blow molding process. Computer-aided design (CAD) software is used to create a detailed design, followed by the approval of the prototype before moving to the next step.

2. Material Selection

The materials used for the mold are of utmost importance in ensuring durability and precision. Typically, high-quality steel alloys are selected for their strength, wear resistance, and ability to withstand high temperatures during production. The choice of material directly impacts the lifespan and performance of the mold.

3. CNC Machining

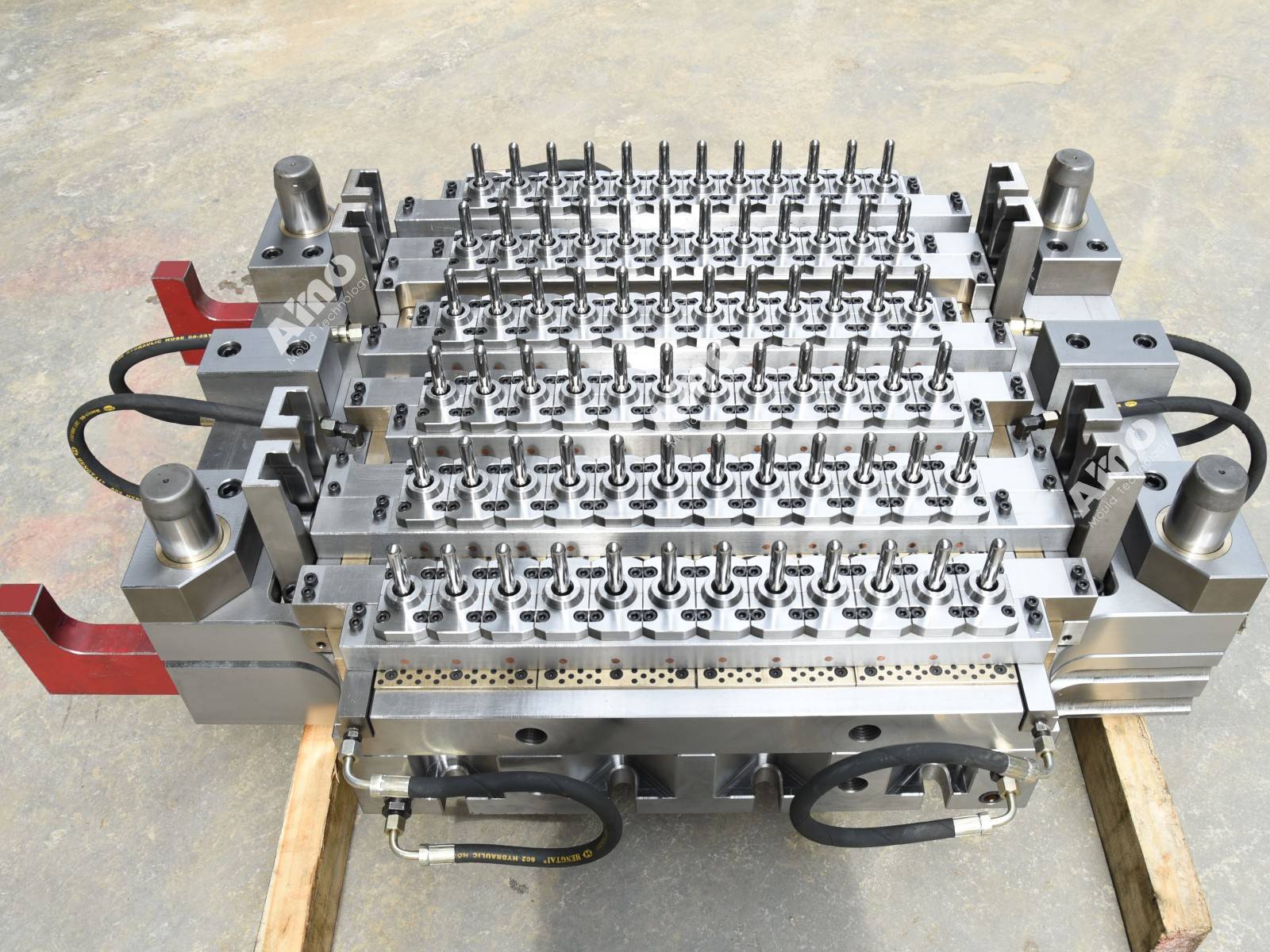

Once the design is finalized, the next step involves CNC (Computer Numerical Control) machining. This process uses precision machinery to cut, shape, and refine the mold's components, ensuring that every detail is perfect. CNC machines ensure the accuracy and consistency required for the preform mold.

4. Heat Treatment

Heat treatment is performed on the mold components to increase their hardness and durability. This step ensures that the mold can endure the high pressures and temperatures during the PET injection molding process. The mold is heated to a specific temperature and then cooled in a controlled manner to achieve the desired properties.

5. Assembly

After the individual components have been machined and treated, they are assembled into a complete preform mold. This step involves carefully aligning the mold cavity, cores, and other critical components to ensure perfect fit and functionality.

6. Quality Control

Each mold is rigorously inspected to ensure it meets the required quality standards. This includes checking for any defects, such as imperfections in the cavity, misalignment, or material flaws. After passing inspection, the mold is tested under real production conditions to confirm that it produces preforms of the highest quality.

7. Final Adjustment and Delivery

Once the mold passes all tests, any necessary final adjustments are made to ensure optimal performance in the injection molding process. Afterward, the mold is packaged and delivered to the client, ready for use in the production of PET bottle preforms.

LEIZHEN - Your Trusted PET Preform Mold Manufacturer

LEIZHEN is a professional manufacturer of PET bottle preform molds based in China. With over 15 years of experience in the mold manufacturing industry, LEIZHEN has established itself as a leader in providing high-quality molds for PET preforms. We specialize in designing and producing molds for a variety of bottle sizes and shapes, ensuring that our clients receive the most precise and durable molds for their production needs.

Our advanced manufacturing processes, combined with our extensive experience, allow us to create molds that meet the highest industry standards. Whether you're looking for custom molds or standard designs, LEIZHEN is committed to providing solutions that improve your production efficiency and product quality.

Contact Us Today!

For more information about our PET bottle preform molds or to inquire about our products and services, please contact us today. We look forward to helping you with all your mold manufacturing needs!