Jar Preform Injection Mould Manufacturers – High-Quality Wholesale Factory Solutions

Introduction

When it comes to producing high-quality plastic jar preforms, choosing the right jar preform injection mould manufacturers is crucial. These preforms are essential for creating durable and reliable plastic jars used in packaging industries such as food, beverages, cosmetics, and pharmaceuticals. A trusted wholesale factory ensures precision engineering, cost-efficiency, and superior performance in every mould produced.

In this article, we will explore the importance of jar preform injection moulds, key features to look for in a manufacturer, and why selecting a professional wholesale factory can benefit your business.

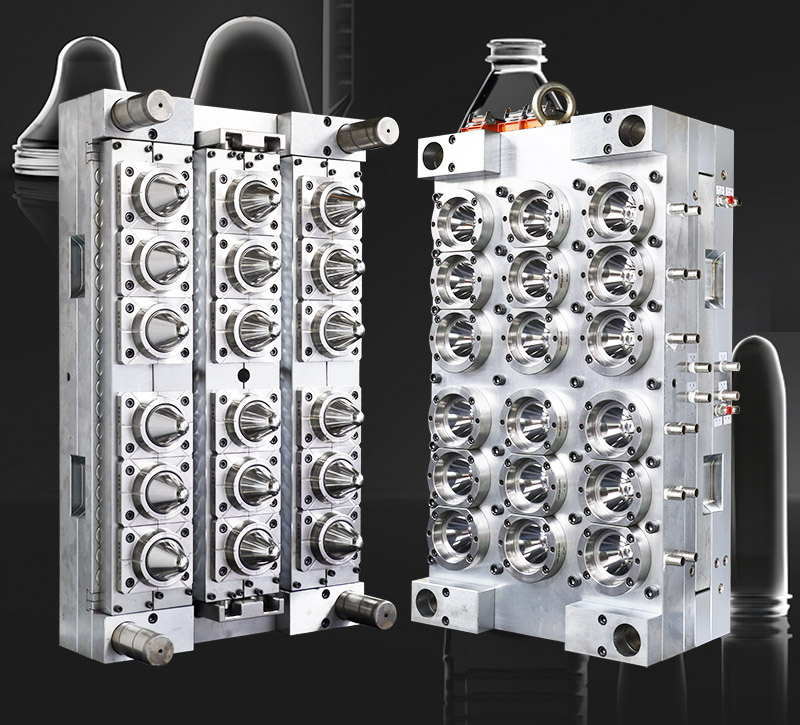

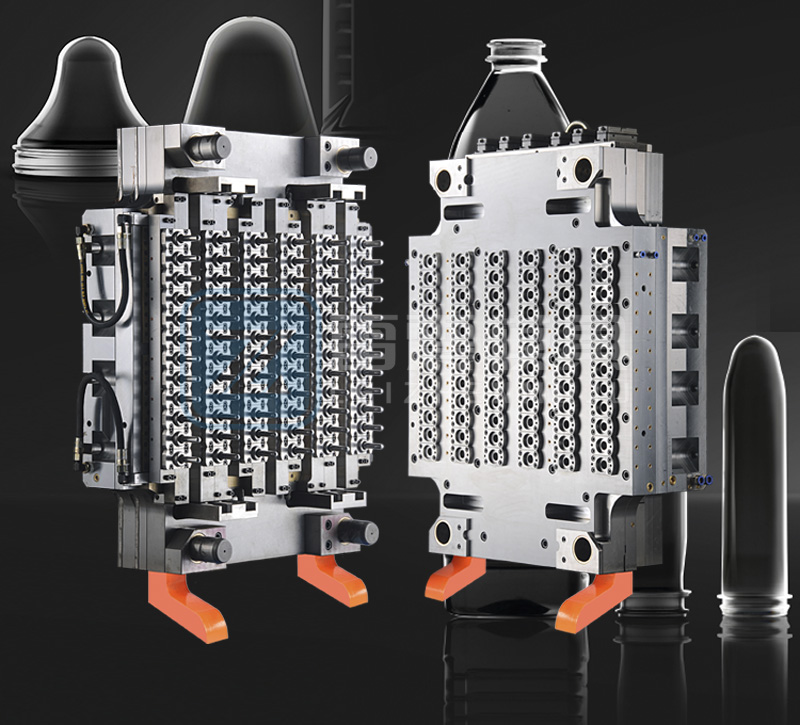

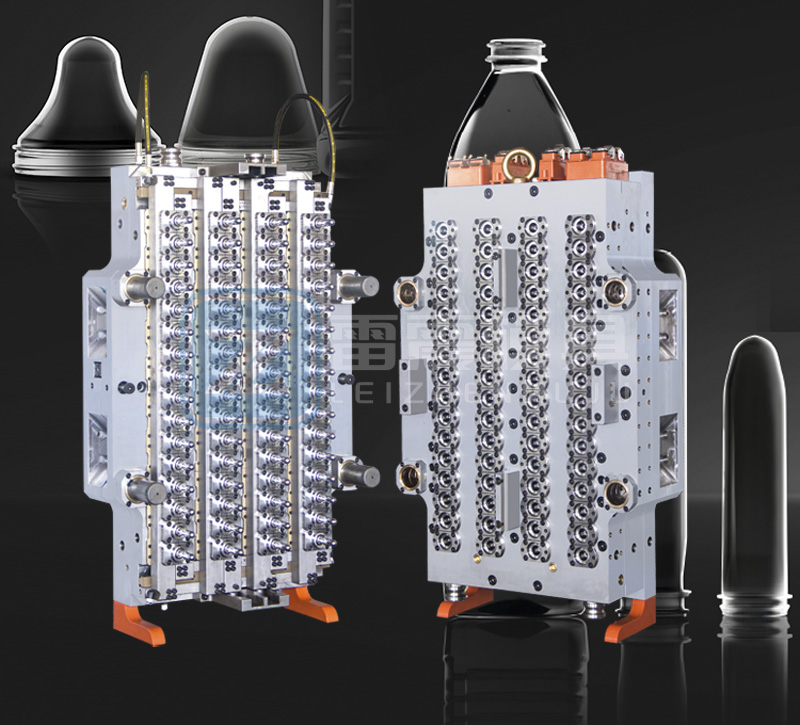

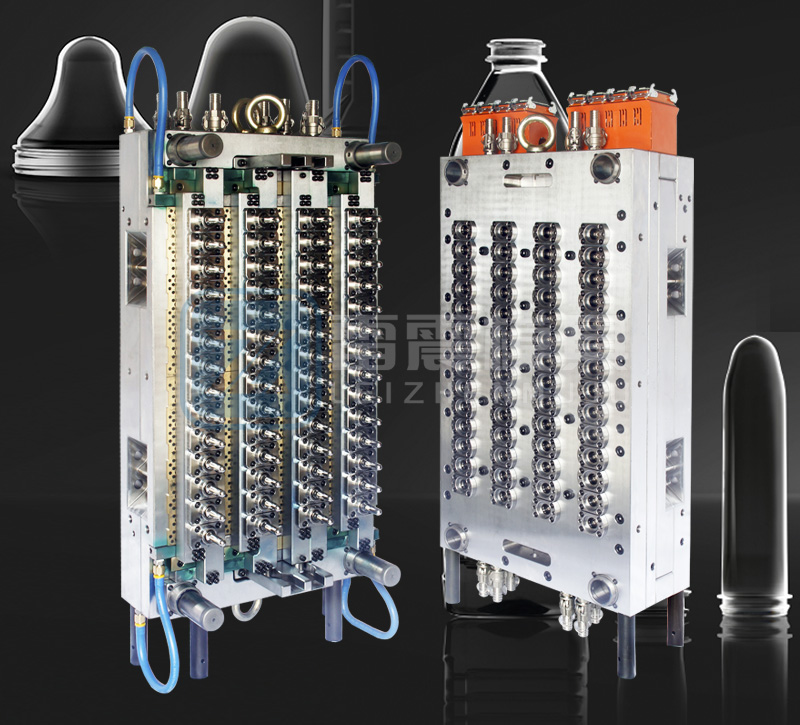

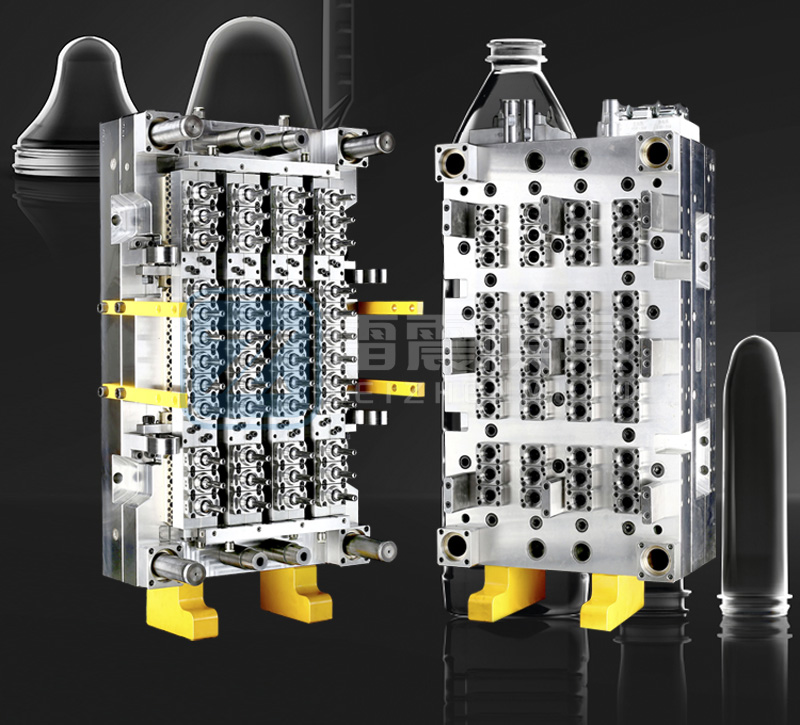

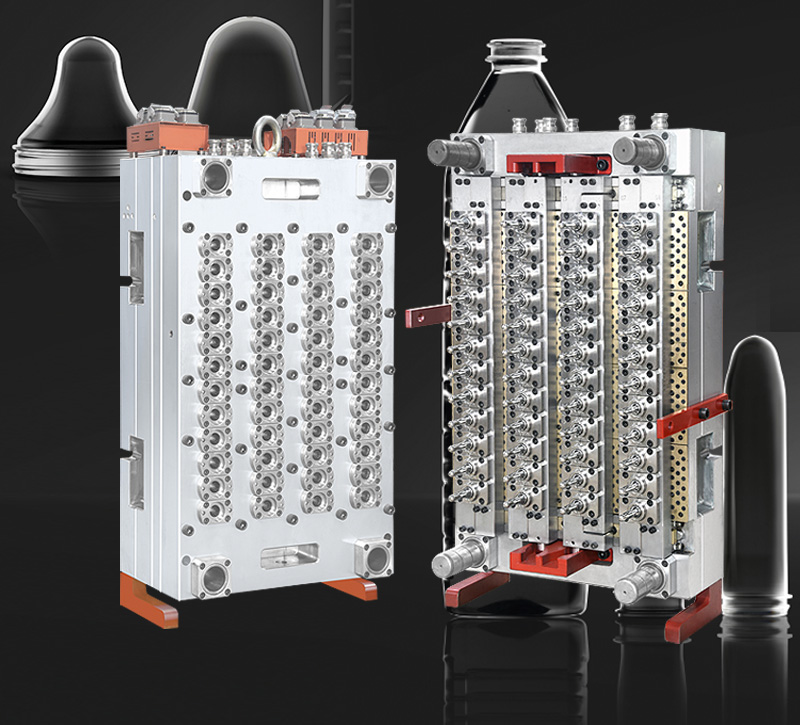

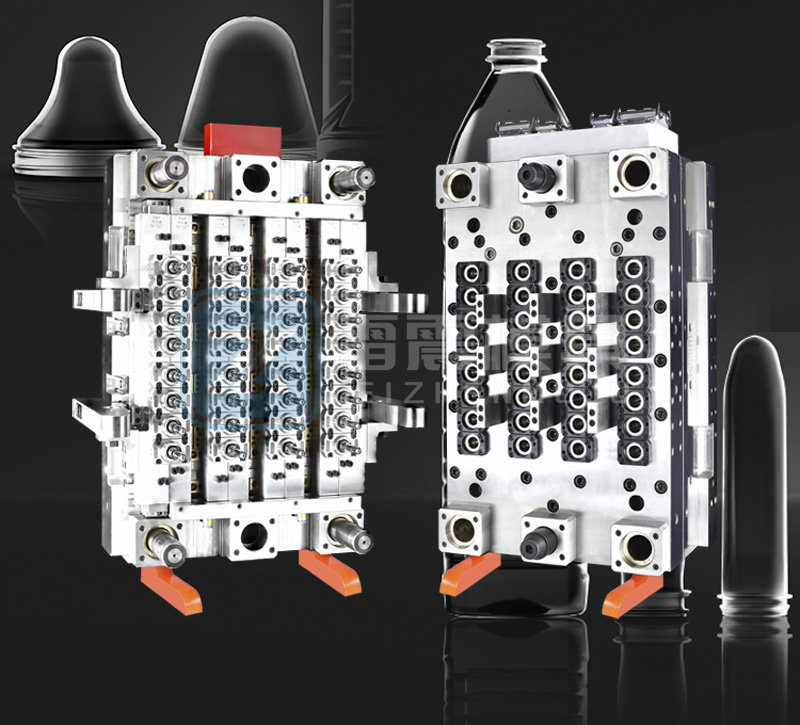

What is a Jar Preform Injection Mould?

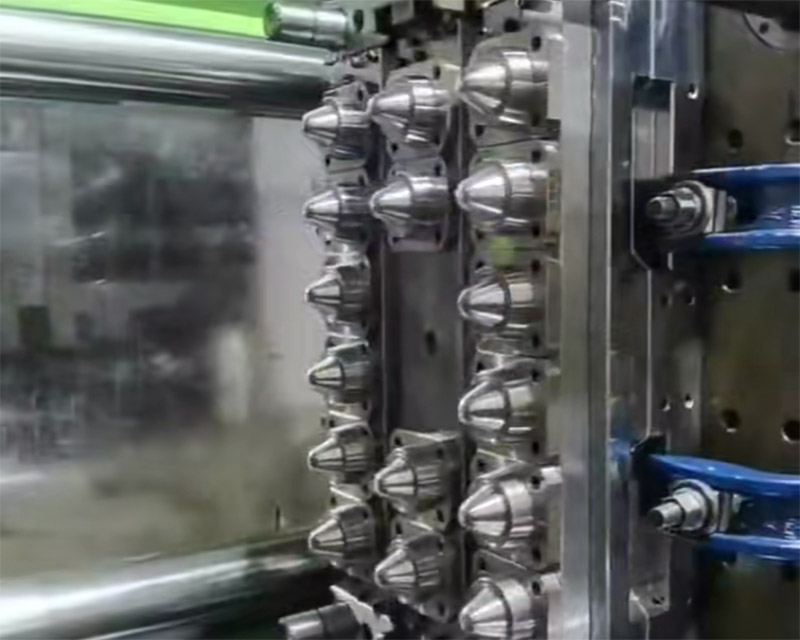

A jar preform injection mould is a specialized tool used in the plastic injection moulding process to create preforms—small, tube-like plastic blanks that are later blown into full-sized jars. These preforms must meet strict quality standards to ensure durability, consistency, and compatibility with blow moulding machines.

Key Applications of Jar Preforms:

✔ Food & Beverage Packaging (Jams, sauces, condiments)

✔ Cosmetics & Personal Care (Creams, lotions, jars)

✔ Pharmaceuticals (Medicine containers)

✔ Industrial Packaging (Chemicals, adhesives)

Why Choose Professional Jar Preform Injection Mould Manufacturers?

Selecting an experienced jar preform injection mould manufacturer ensures high precision, durability, and cost-effective production. Here’s what to look for:

1. High-Quality Materials & Durability

Top manufacturers use premium-grade steel (such as H13, P20, or S136) to ensure long-lasting moulds that withstand high-pressure injection cycles.

2. Precision Engineering & Customization

A reliable wholesale factory offers custom designs tailored to your specific jar dimensions, thread types, and capacity requirements.

3. Advanced Manufacturing Technology

Modern CNC machining, EDM, and high-speed milling ensure tight tolerances and smooth finishes for defect-free preforms.

4. Competitive Pricing & Bulk Supply

Partnering with a wholesale factory allows for cost savings, especially for large-volume orders, without compromising quality.

5. Fast Turnaround & After-Sales Support

Leading manufacturers provide quick production cycles,模具 testing, and technical support to minimize downtime.

How to Identify the Best Wholesale Factory for Jar Preform Moulds

When sourcing jar preform injection moulds, consider the following factors:

✅ Industry Experience – Look for manufacturers with a proven track record in plastic injection moulds.

✅ Certifications & Standards – Ensure compliance with ISO, FDA, or other industry certifications.

✅ Customer Reviews & Case Studies – Check testimonials and past projects for reliability.

✅ Sample Testing – Request mould samples to verify quality before bulk production.

✅ Global Export Capabilities – If importing, confirm the supplier’s experience in international shipping.

Conclusion

Choosing the right jar preform injection mould manufacturers is essential for producing high-quality, consistent plastic jars. A professional wholesale factory with advanced technology, customization options, and competitive pricing can significantly enhance your packaging efficiency and product quality.

For businesses seeking reliable jar preform moulds, partnering with an experienced manufacturer ensures long-term success in the competitive packaging industry.