Expert Manufacturing of Wide-Mouth/ Jar PET Preform Molds

LEIZHEN Mold Company specializes in designing and producing high-performance wide-mouth PET preform molds for jars, containers, and packaging solutions requiring easy filling, scooping, or pouring. Our molds are engineered to meet the demands of food, cosmetics, household chemicals, and industrial sectors, combining durability, precision, and user-friendly functionality. Discover how we deliver innovative wide-opening jar molds that drive efficiency and brand appeal.

Applications of Wide-Mouth PET Preform Molds

Food Packaging: Jars for sauces, spreads, nuts, and snacks (40mm+ neck diameters).

Cosmetics & Personal Care: Creams, lotions, and balms with smooth, wide-access designs.

Household Products: Detergents, cleaning agents, and bulk storage containers.

Industrial Packaging: Chemical-resistant wide-neck containers for safe handling.

Key Features of LEIZHEN’s Wide-Mouth Mold Designs

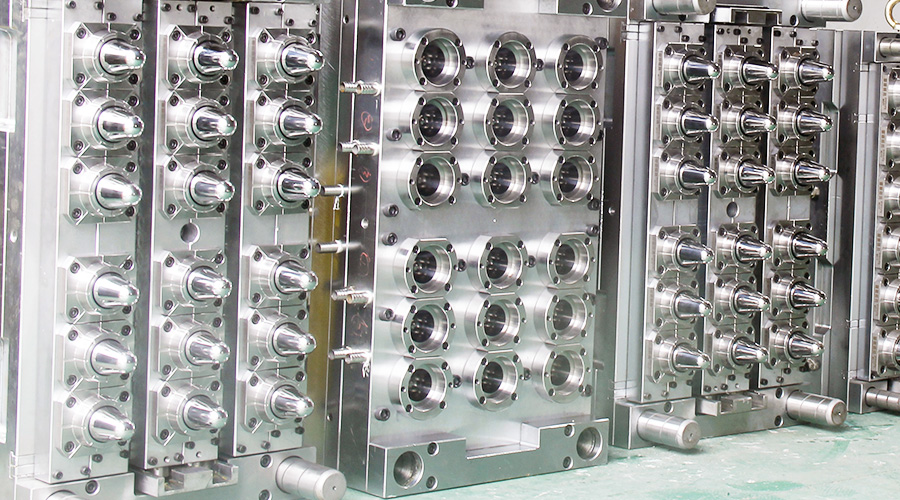

Reinforced Thread & Seal Systems

Robust thread designs for secure closures, preventing leaks in viscous products.

Optimized sealing surfaces compatible with induction liners or tamper-evident caps.

Uniform Wall Thickness Distribution

Advanced mold flow simulation ensures even material distribution, reducing warpage and enhancing jar stability.

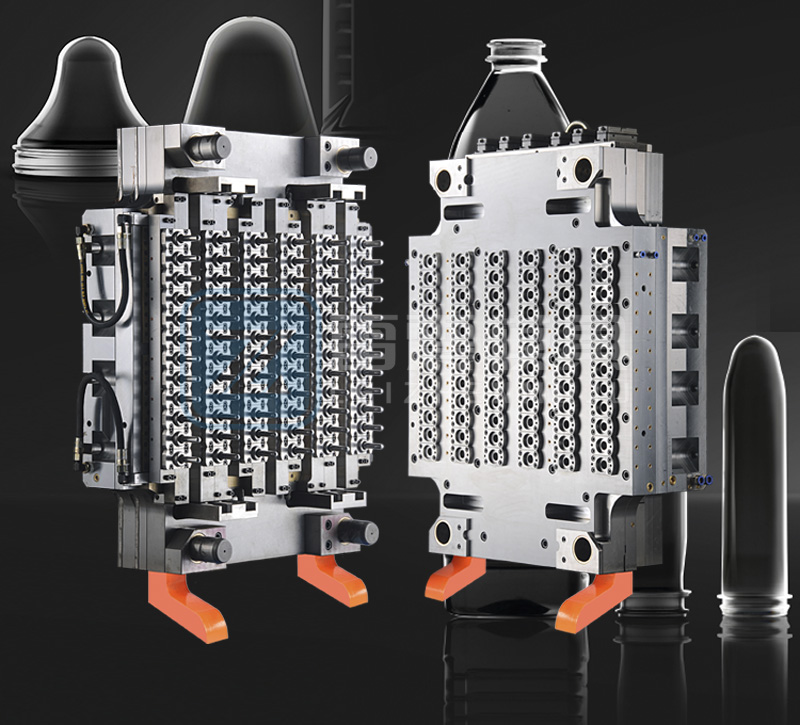

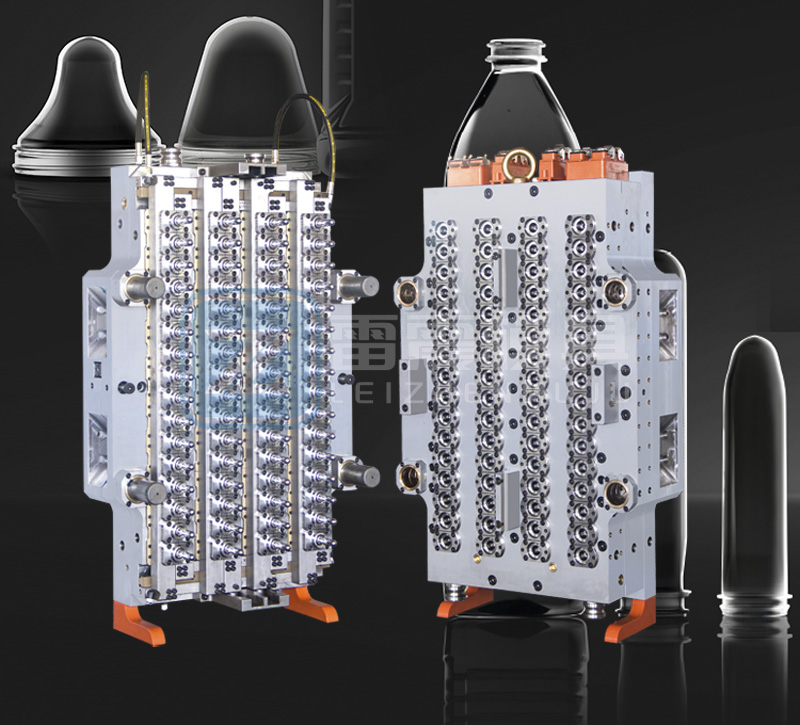

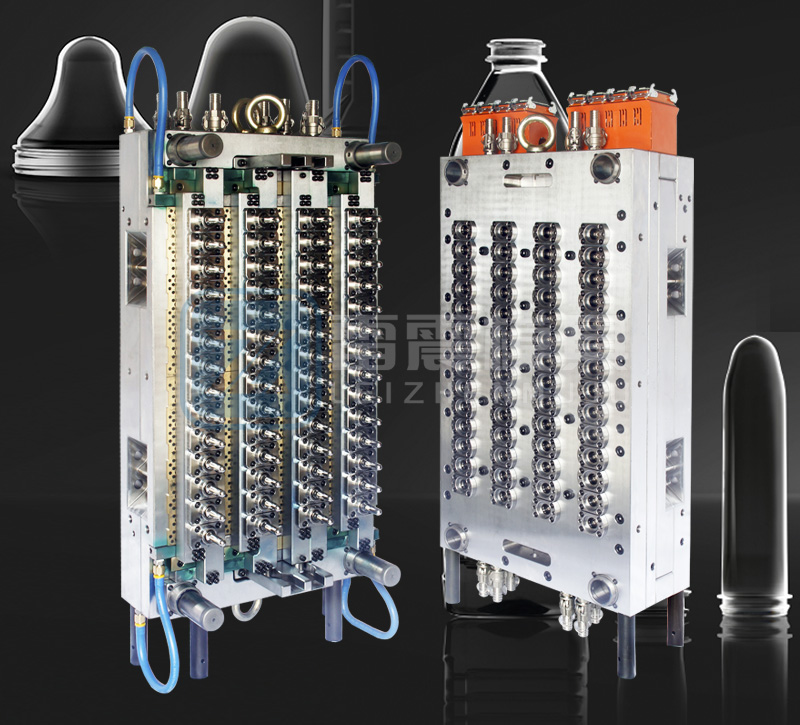

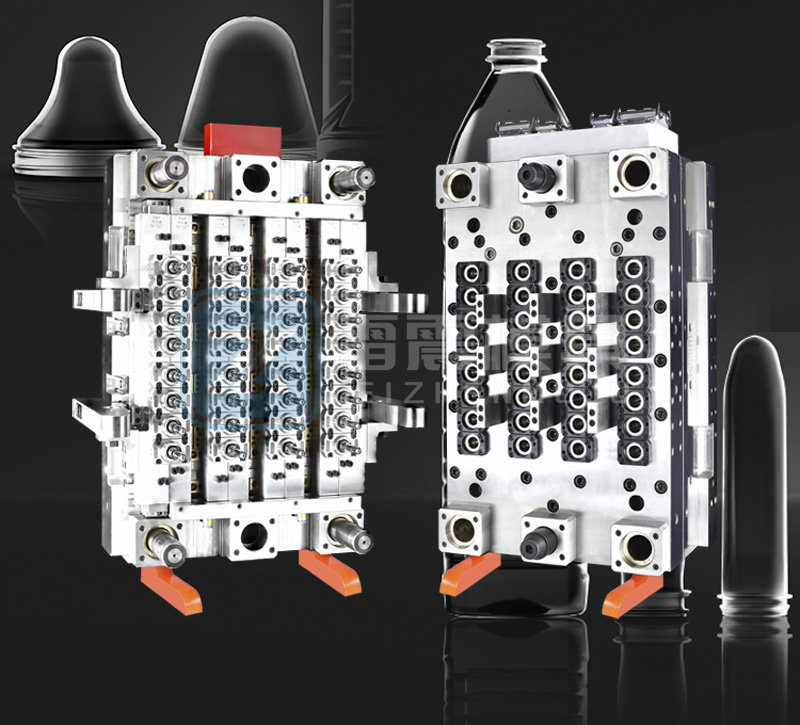

Enhanced Cooling Channel Layout

Strategically designed cooling systems minimize cycle times for thick-walled jars.

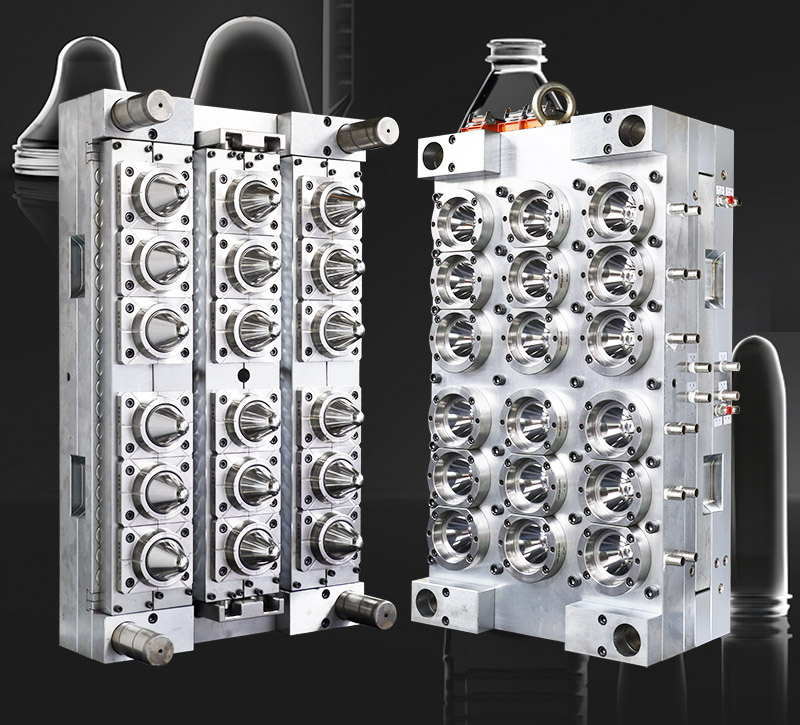

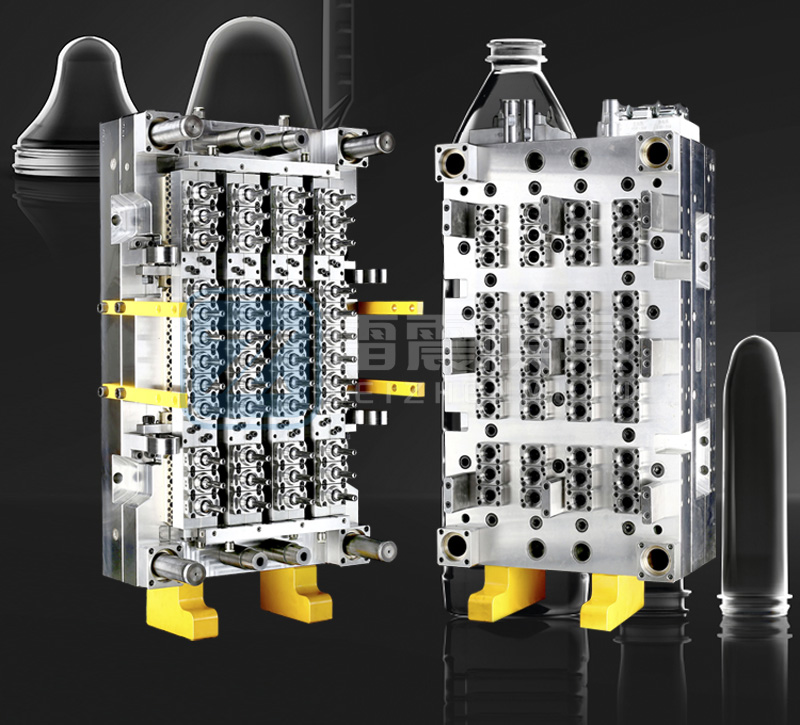

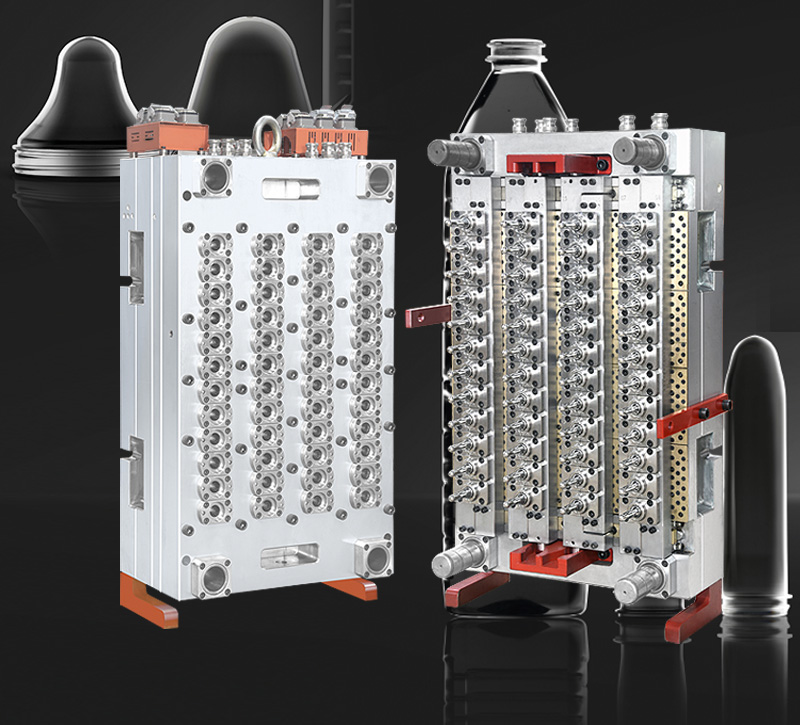

Multi-Cavity Configurations

Molds with 4 to 96 cavities for high-volume production, tailored to jar sizes (100ml to 5L+).

Technical Advantages in Wide-Mouth Mold Manufacturing

Material Expertise: Use of hardened steel (H13, Stainless Steel 420) and coatings (chrome, nitriding) for wear resistance and extended lifespan.

Precision CNC Machining: 5-axis CNC technology achieves micron-level accuracy (±0.02mm) for seamless cap compatibility.

Hot Runner Systems: Integrated hot runners reduce material waste and ensure consistent fill rates for wide necks.

SEO Focus: High-precision wide-neck molds, CNC-machined jar preform molds.

Customization Options

Neck Diameters: Standard sizes (38mm, 40mm, 45mm, 48mm) or fully custom specifications.

Thread Profiles: ISO, PCO, or bespoke threading for unique cap requirements.

Surface Finishes: Glossy, matte, or textured finishes for brand-specific aesthetics.

Quality Assurance & Compliance

Rigorous Testing: Cycle testing (500,000+ cycles) and CMM inspections for dimensional accuracy.

Certifications: Compliant with FDA, EU, and ISO standards for food safety and recyclability.

Durability Guarantee: Molds withstand high-viscosity materials (e.g., peanut butter, hair masks) without degradation.

Why Choose LEIZHEN for Wide-Mouth Jar Molds?

✅ End-to-End Solutions: From CAD design to mass production support.

✅ Fast Turnaround: Prototype delivery in 15-20 days.

✅ Global Logistics: Doorstep delivery with anti-corrosion packaging.

✅ 24/7 Technical Support: Expert assistance for mold optimization and troubleshooting.

Elevate Your Packaging with LEIZHEN’s Expertise!

Whether you need high-volume wide-mouth molds or niche designs, we deliver precision, reliability, and cost-efficiency. Contact us today for a free consultation!