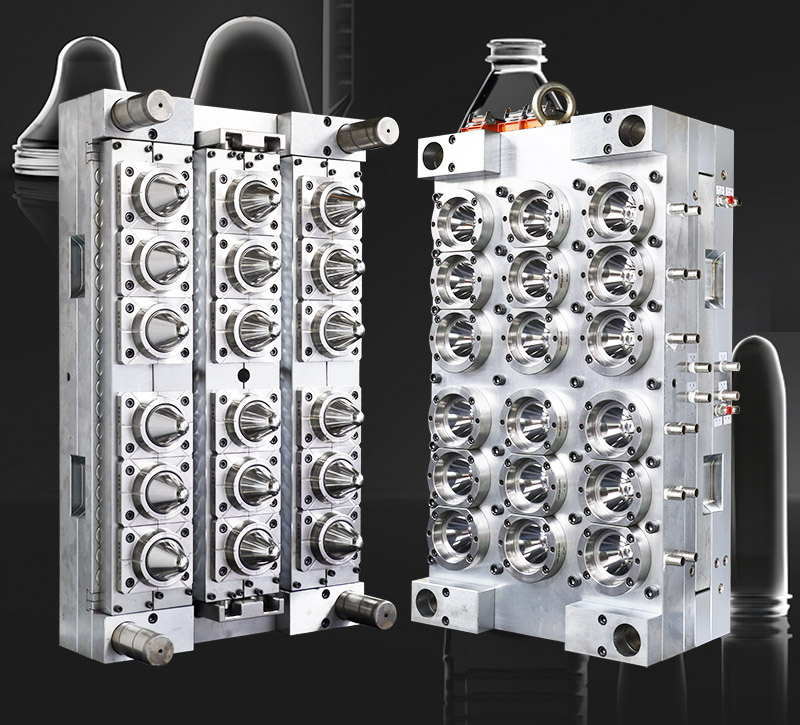

LEIZHEN Mold Company: Proper Maintenance Guide for PET Preform Molds

Extending the lifespan and ensuring peak performance of your PET preform molds requires consistent care and preventive maintenance. At LEIZHEN Mold Company, we provide expert guidance to help global clients maximize mold efficiency, reduce downtime, and avoid costly repairs. Follow these proven practices to keep your bottle molds in optimal condition.

1. Regular Cleaning & Debris Removal

Post-Production Cleaning: Use non-abrasive solvents to remove PET residue, oils, and contaminants from cavities, cores, and cooling channels.

Ultrasonic Cleaning: For deep cleaning, employ ultrasonic technology to eliminate microscopic particles that cause wear.

Avoid Harsh Chemicals: Prevent corrosion by using pH-neutral cleaners compatible with mold steel.

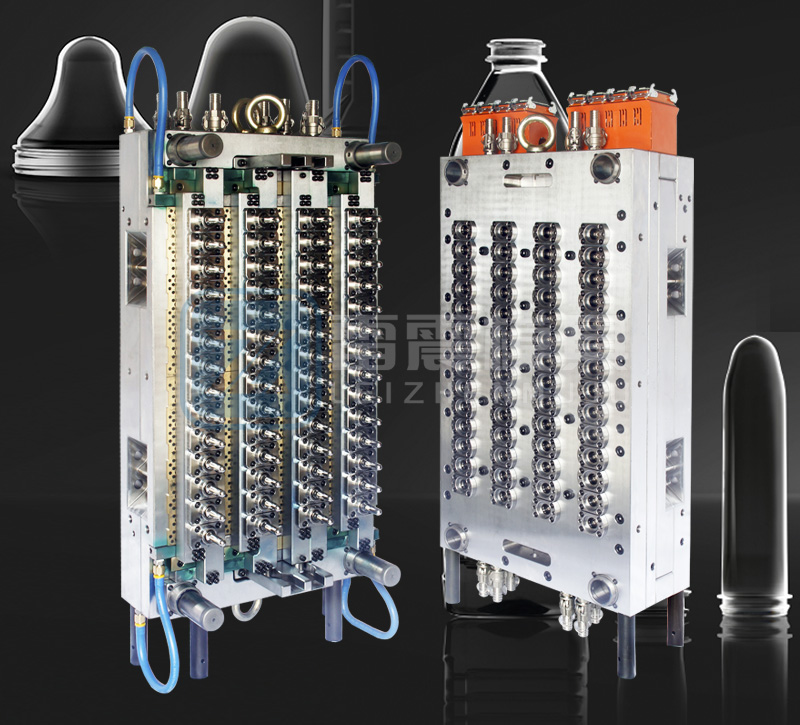

2. Lubrication of Moving Components

Ejector Pins & Slides: Apply high-temperature grease to reduce friction and prevent seizing during high-speed cycles.

Guide Rails & Bushings: Lubricate weekly with silicone-based oils to ensure smooth operation.

Avoid Over-Lubrication: Excess grease attracts dust and may clog cooling systems.

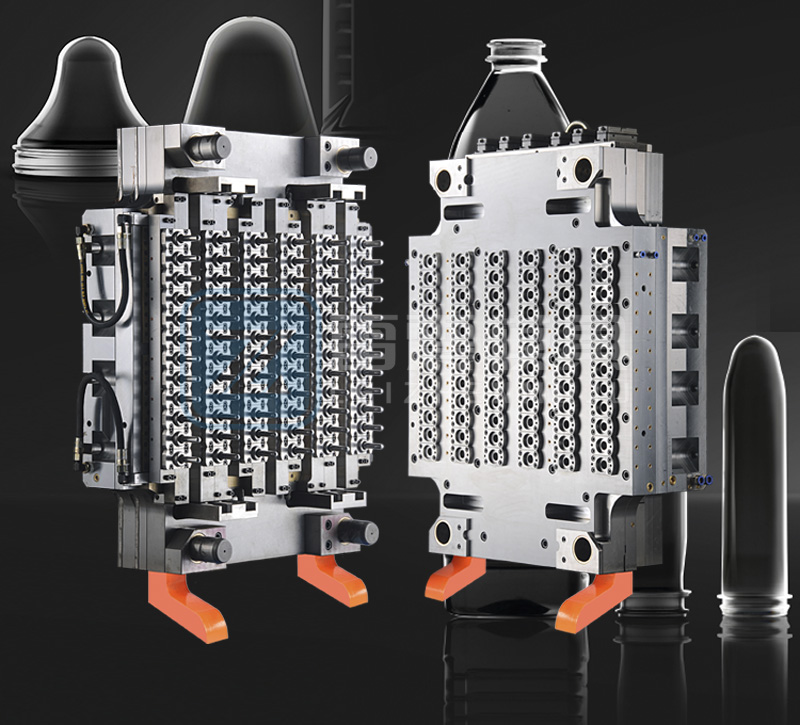

3. Cooling System Maintenance

Flush Cooling Channels: Regularly descale mineral deposits or biofilm buildup using citric acid or specialized solutions.

Check for Leaks: Inspect O-rings and connections to prevent water ingress, which can cause rust or electrical damage.

Monitor Temperature: Ensure stable cooling rates (±1°C) to prevent thermal stress cracks.

4. Rust Prevention & Surface Protection

Anti-Corrosion Coatings: Apply rust inhibitors like VCI (Vapor Corrosion Inhibitor) films during storage.

Climate-Controlled Storage: Keep molds in dry environments (humidity <50%) with silica gel desiccants.

Chrome Plating: For long-term protection, opt for surface treatments to enhance wear resistance.

5. Routine Inspection & Wear Detection

Check Cavity Surfaces: Use magnifying tools to identify scratches, pitting, or micro-cracks.

Measure Dimensional Accuracy: Verify critical tolerances (e.g., neck finish) with CMM or laser scanners.

Monitor Cycle Counts: Track production cycles to schedule preventive maintenance (e.g., after 100,000 cycles).

6. Proper Handling & Storage

Use Protective Covers: Shield molds with foam or padded wraps during transport to avoid impact damage.

Vertical Storage: Store molds upright to prevent warping of cores and cavities.

Documentation: Label molds with maintenance history, cycle counts, and repair logs.

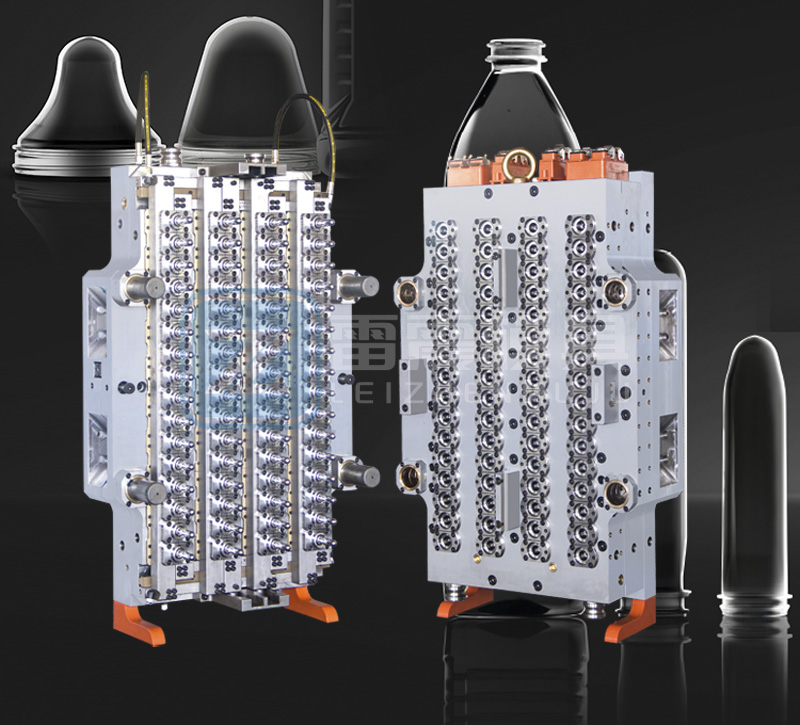

7. Professional Repair & Refurbishment

Address Minor Damage Early: Repair worn ejector pins or damaged threads promptly to avoid escalation.

Re-Polishing Services: Restore surface finish to eliminate defects affecting preform aesthetics.

Hot Runner System Checks: Test heaters and nozzles for electrical faults or blockages.

Why Trust LEIZHEN for Mold Care?

✅ Expert Maintenance Kits: Customized toolkits for cleaning, lubrication, and inspection.

✅ Global Technical Support: 24/7 assistance for troubleshooting and emergency repairs.

✅ Replacement Parts: OEM-standard components for seamless compatibility.

✅ Training Programs: On-site or virtual workshops for your maintenance team.

Maximize Your Mold’s Lifespan Today!

Partner with LEIZHEN Mold Company for durable PET preform molds backed by world-class maintenance support. Contact us to schedule a service or download our free maintenance checklist!