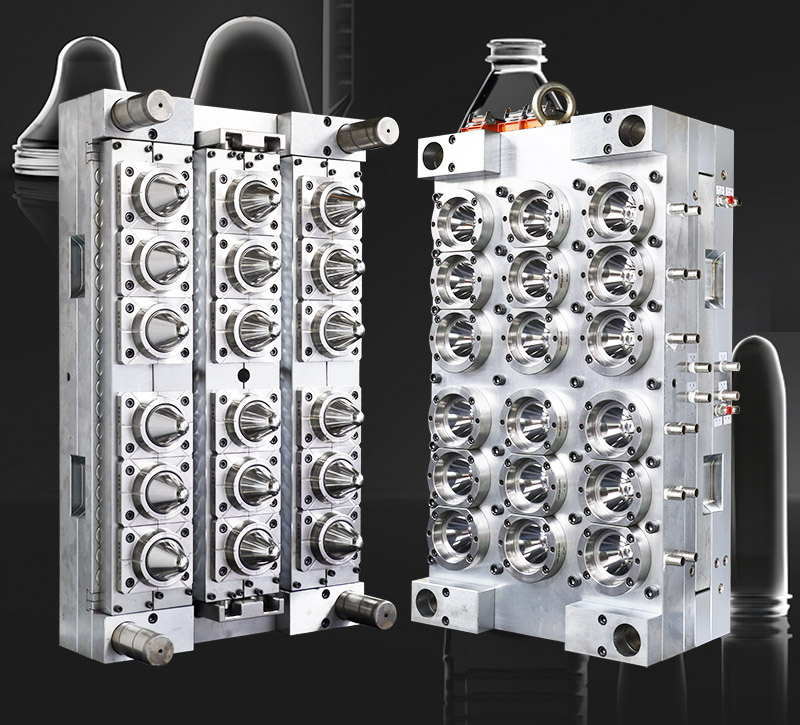

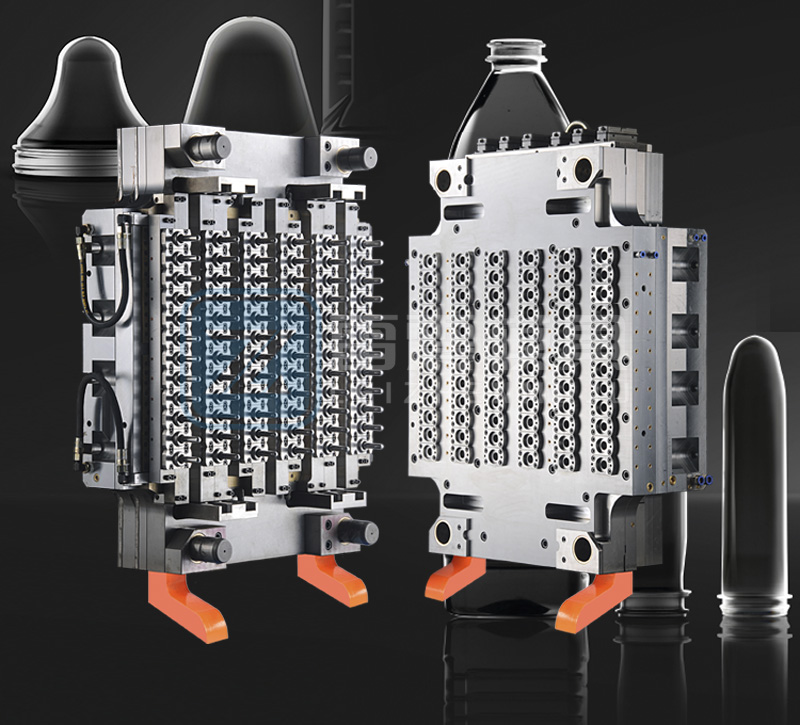

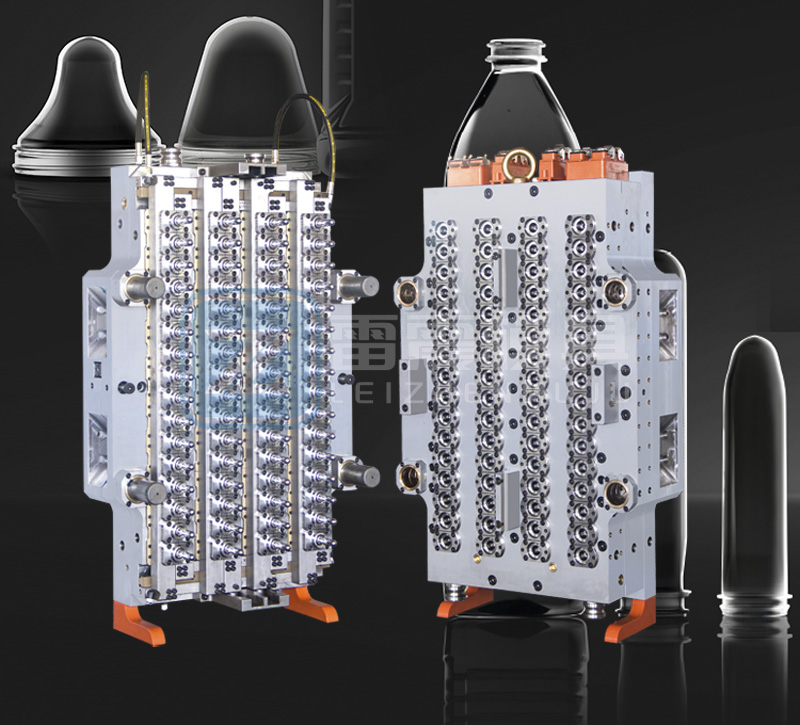

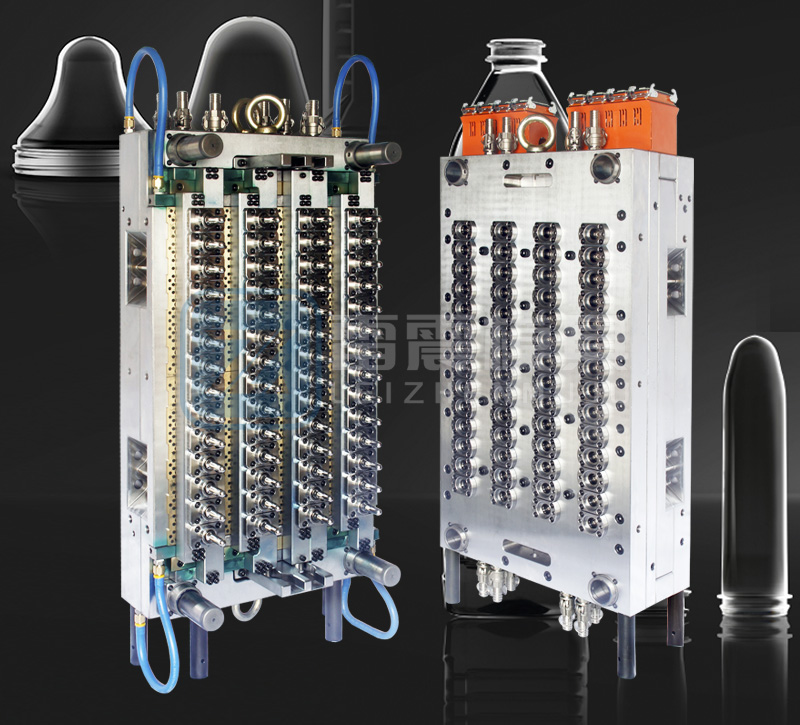

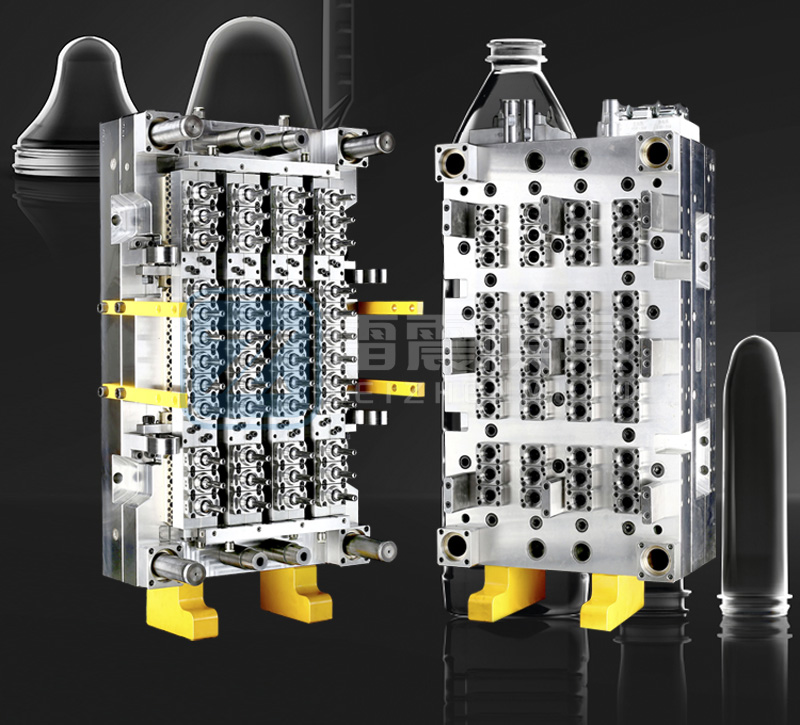

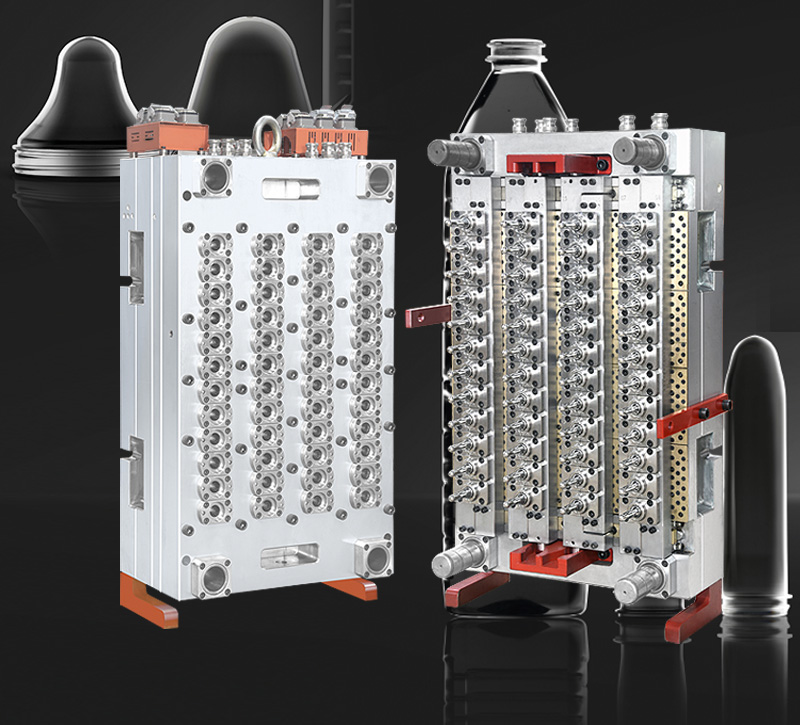

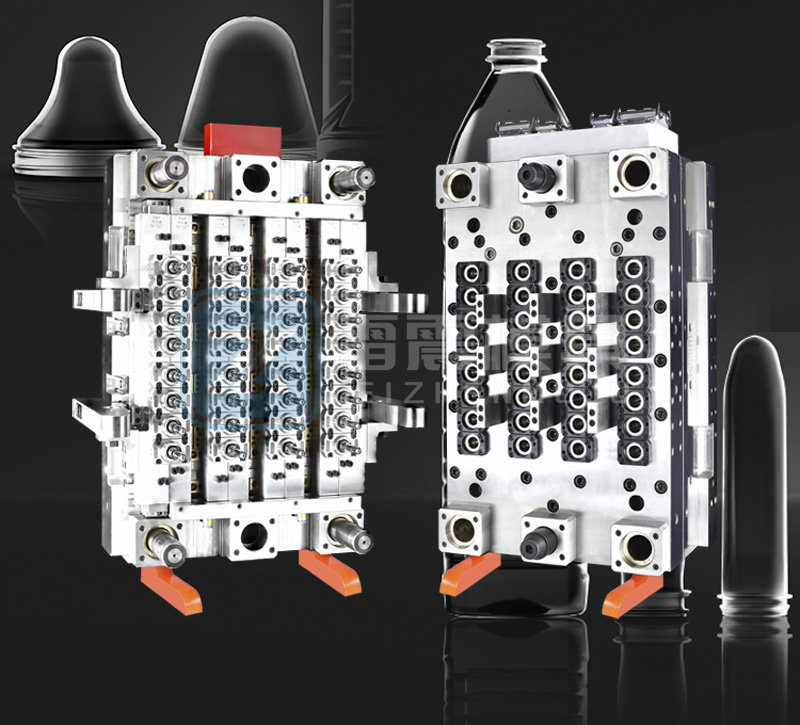

Complete Guide to PET Preform Mold Manufacturing, Maintenance & Production

Key Considerations in PET Preform Mold Manufacturing

Manufacturing high-quality PET preform molds requires precision engineering and meticulous attention to detail. Here are the critical aspects to consider:

Material Selection

Use premium mold steels such as H13, S136, or 420 stainless steel for superior corrosion resistance and durability. Critical components like injection nozzles and gate inserts should utilize hardened steels or carbide materials to withstand abrasive PET materials.

Cooling System Design

An efficient cooling system is paramount for consistent preform quality. Implement conformal cooling channels that follow the contour of the cavity to ensure uniform temperature distribution. Proper cooling reduces cycle time by up to 30% and minimizes residual stresses in preforms.

Venting Design

Adequate venting prevents gas traps and burn marks. Vent depths should be carefully calculated (typically 0.015-0.02mm for PET) and placed strategically along parting lines and ejector pins.

Surface Finish

Cavity surfaces require high-polish finishes (typically SPI A1 or better) to ensure easy ejection and excellent preform surface quality. Textured surfaces should be avoided in the main body to prevent sticking.

Dimensional Accuracy

Maintain tight tolerances (±0.005mm) for critical dimensions like neck finishes and gate areas. Implement proper shrinkage compensation (PET typically shrinks 1.5-2.0%) in mold design.

Gate Design

Hot runner systems with needle-valve gates provide precise control over injection. Gate geometry must be optimized to prevent visual defects and ensure proper sealing.

Essential Mold Maintenance Procedures

Daily Maintenance

Clean mold surfaces with specialized mold cleaners before and after production runs

Lubricate moving components with high-temperature mold lubricants

Inspect for wear on guide pins, bushings, and ejector systems

Verify proper function of thermal control systems

Weekly Maintenance

Disassemble and thoroughly clean venting channels

Inspect and polish any minor surface imperfections

Check hot runner system for proper heating and electrical continuity

Verify cooling channel flow rates and temperatures

Monthly Maintenance

Complete disassembly for deep cleaning and inspection

Measure critical dimensions against original specifications

Replace worn components (ejector pins, seals, heaters)

Re-calibrate temperature controllers and sensors

Seasonal/Annual Maintenance

Perform non-destructive testing for stress cracks

Re-polish cavity surfaces if needed

Upgrade obsolete components

Update maintenance documentation

Producing High-Quality PET Preforms: Process Parameters

Material Preparation

Dry PET resin properly to moisture content below 50 ppm. Use dehumidifying dryers with -40°C dew point for 4-6 hours at 150-160°C.

Injection Molding Parameters

Temperature Settings:

Barrel zones: 260-285°C (gradual increase toward nozzle)

Nozzle temperature: 280-285°C

Mold temperature: 8-12°C (cavity), 8-15°C (core)

Hot runner: 285-295°C

Injection Parameters:

Injection speed: High initial speed (90-95% of maximum)

Switchover point: 95-98% of cavity filled (switch to packing phase)

Holding pressure: 40-60% of injection pressure

Cooling time: 8-12 seconds (depending on wall thickness)

Critical Quality Control Points

Visual Inspection: Check for bubbles, black spots, cloudiness, or gate defects

Dimensional Verification: Measure neck finish dimensions, overall length, and wall thickness distribution

Weight Control: Maintain consistent preform weight within ±0.1g tolerance

Intrinsic Viscosity (IV): Monitor IV drop to ensure proper molecular weight

Crystallinity: Ensure amorphous structure (typically <5% crystallinity)

Troubleshooting Common Defects

Stretching Lines: Increase mold temperature, optimize injection speed

Cloudiness: Improve drying, check for contamination

Gate Defects: Adjust gate temperature, optimize holding pressure

Short Shots: Increase injection pressure, check venting

Yellowing: Reduce barrel temperatures, check thermal degradation