PET Preform Molding Solutions: A Detailed Guide to Manufacturing

In the world of packaging, the humble PET preform is the unsung hero. It is the foundational, test-tube-shaped piece of plastic that, when heated and blown, becomes the ubiquitous PET bottle containing everything from water and soda to sauces and cosmetics. The quality of the final bottle is directly dependent on the quality of the preform.

This guide provides a comprehensive look into PET preform manufacturing, covering the process, key technologies, critical parameters, and solutions for common challenges.

What is a PET Preform?

A PET preform is a injection-molded tube of Polyethylene Terephthalate (PET) polymer with a finished neck thread (the same threads that the bottle cap screws onto). The body of the preform is thick-walled and will be stretched and expanded during the blow molding stage to form the thin-walled, transparent bottle.

The PET Preform Manufacturing Process: A Step-by-Step Breakdown

The manufacturing of PET preforms is primarily done through Injection Molding. Here’s a detailed breakdown of the process:

1. Material Preparation: Drying

Why: PET is highly hygroscopic, meaning it absorbs moisture from the atmosphere.

Process: PET resin must be dried to a very low moisture content (typically below 50 ppm or 0.005%) using a dehumidifying dryer. Inadequate drying causes a hydrolysis reaction during melting, leading to a significant loss of Intrinsic Viscosity (IV), which weakens the material and causes brittleness and hazing.

2. Injection Molding: The Heart of the Process

Melting: The dried PET pellets are fed into the injection molding machine's barrel, where they are heated to a precise melt temperature (typically between 265°C and 285°C).

Injection: The molten PET is injected at high pressure into a multi-cavity mold. This mold is cooled by a precise water temperature control system to rapidly solidify the plastic.

Critical Elements:

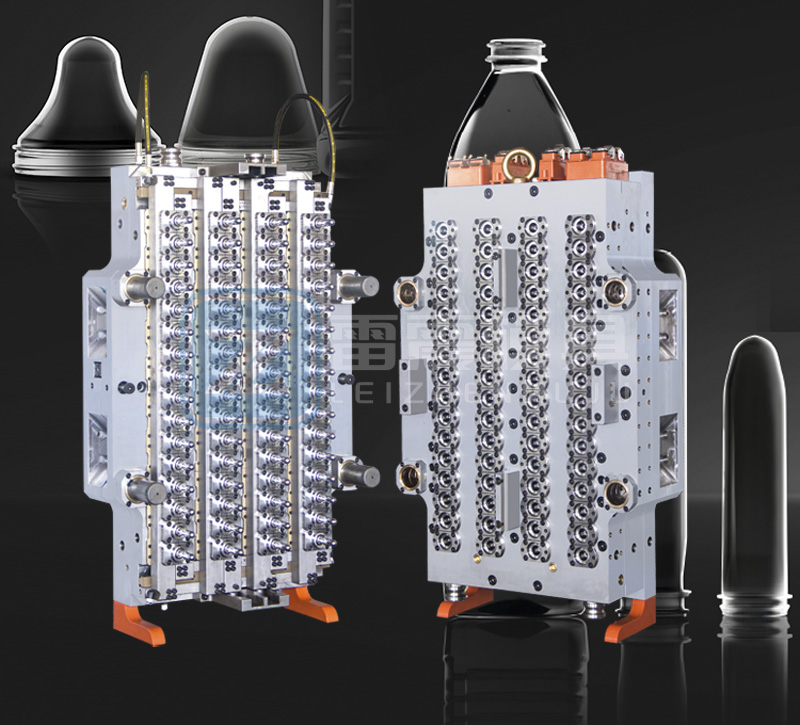

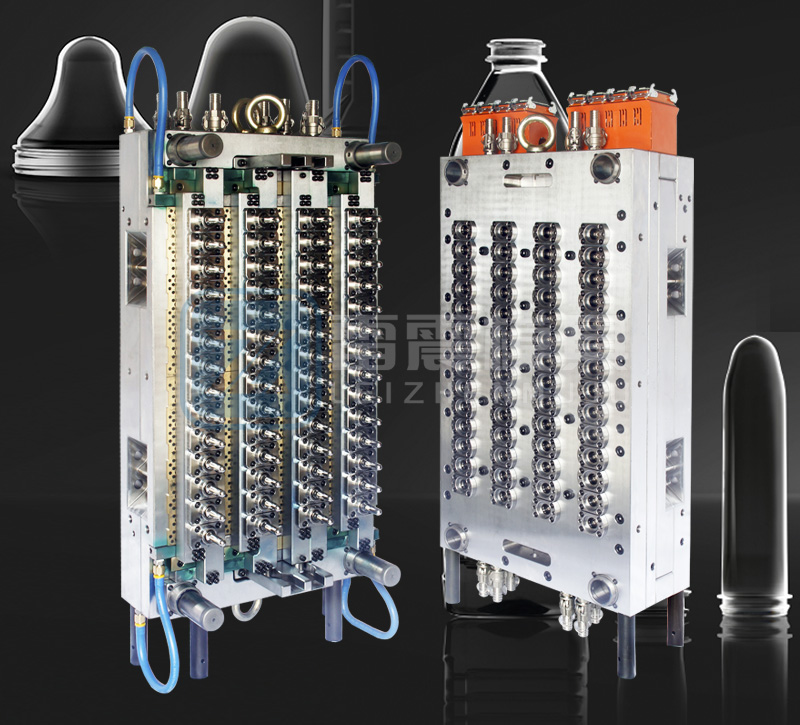

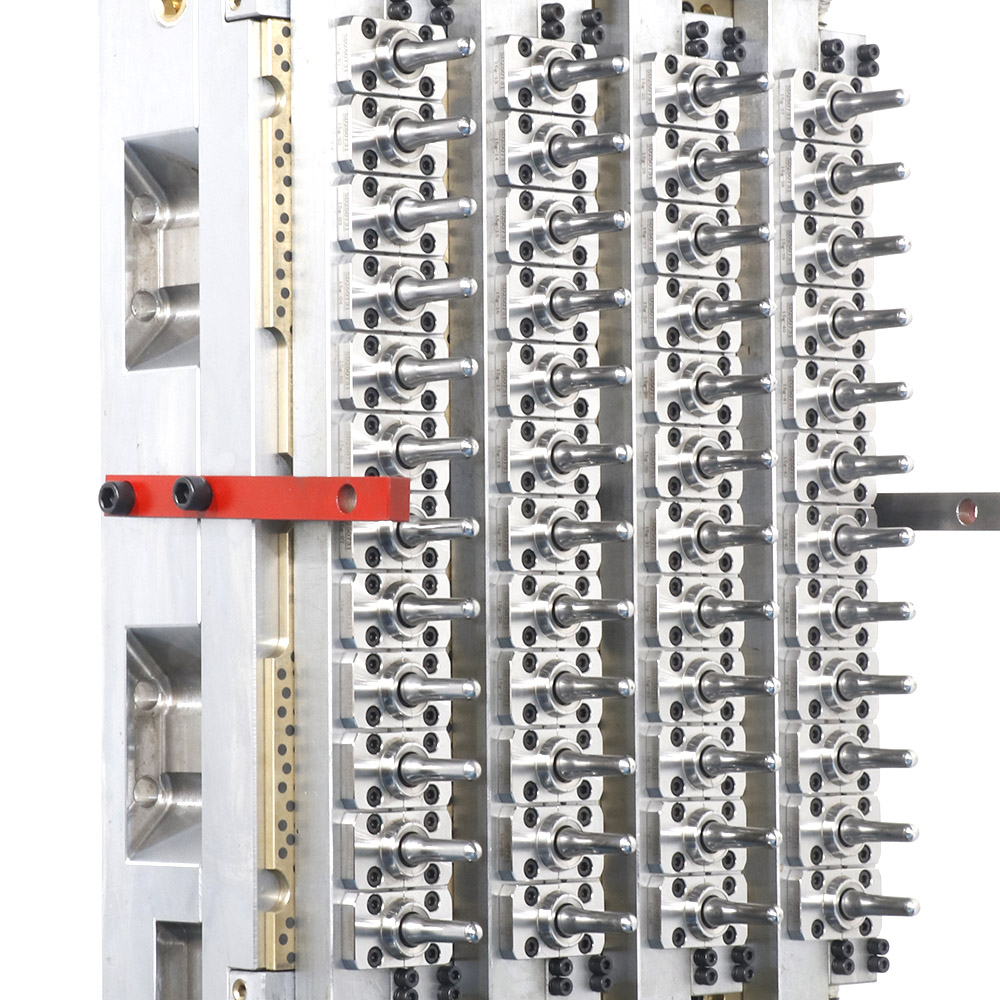

Hot Runner System: A temperature-controlled manifold that delivers the molten PET to the mold cavities without cold sprues or runners, ensuring no material waste and consistent heating.

Cooling Circuit: The most time-consuming part of the cycle. Efficient cooling is essential for achieving high production rates and preventing crystallinity (whitening) in the preform body.

3. Ejection and Handling

Once cooled and solidified, the preforms are automatically ejected from the mold.

They are often handled by robots to prevent scratches, marks, or contamination.

They are typically placed on a cooling conveyor to stabilize before packaging or are directly transported to a blow molding machine for immediate bottling (in a one-step ISBM process).

Key Technologies for a High-Quality PET Preform Molding Solution

A successful PET preform operation relies on integrating several advanced technologies.

High-Performance Injection Molding Machines: Machines with robust clamping force, precise injection control (e.g., servo-electric drives for energy efficiency and accuracy), and a plasticizing unit designed for PET's specific melt characteristics.

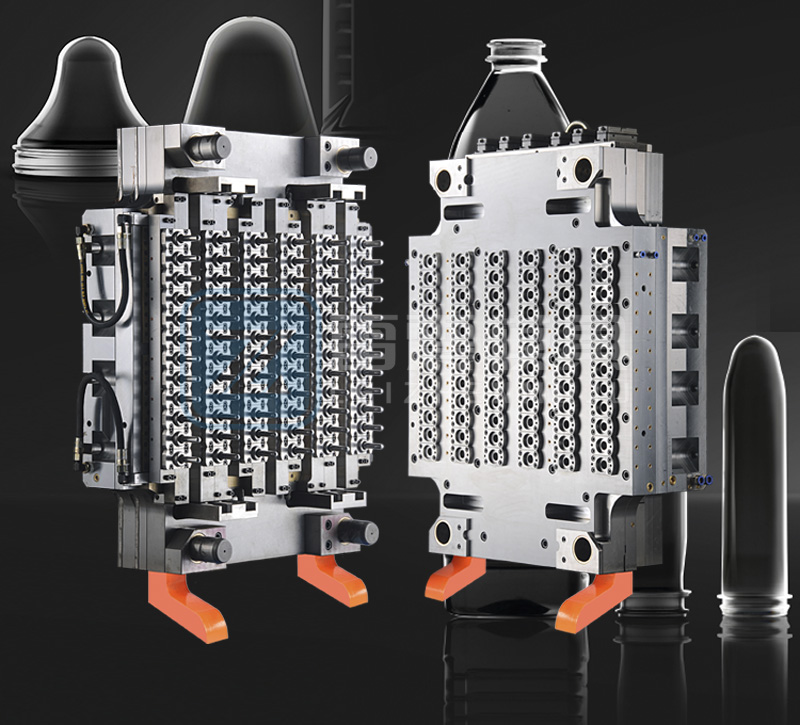

Advanced Hot Runner Systems: These are critical. A good hot runner system provides:

Balanced Filling: Ensures each cavity receives the same amount of material at the same pressure and temperature.

Thermal Uniformity: Prevents "hot spots" or "cold spots" that can cause degradation or incomplete filling.

Minimal Shear: Low-shear designs prevent a drop in IV, maintaining the material's strength.

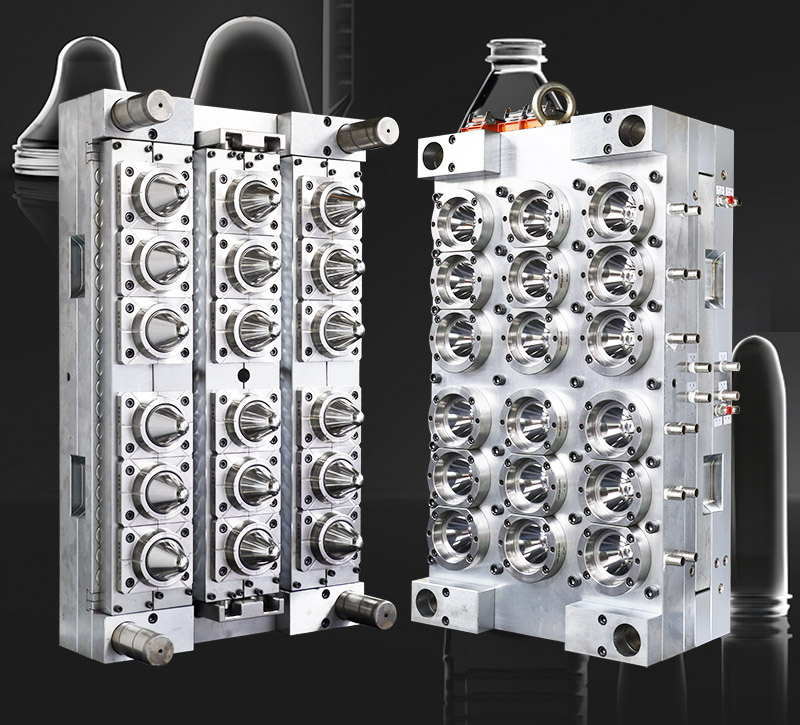

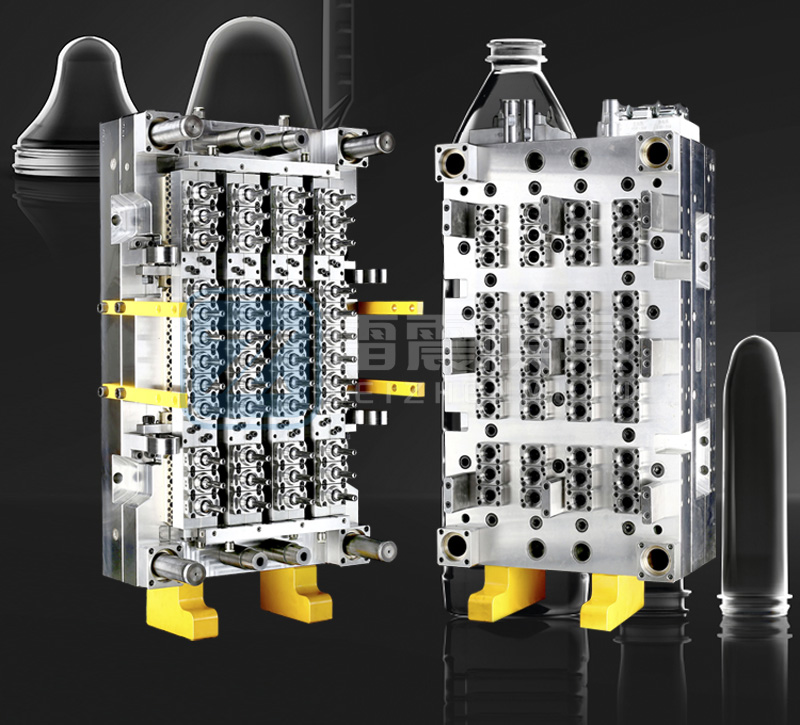

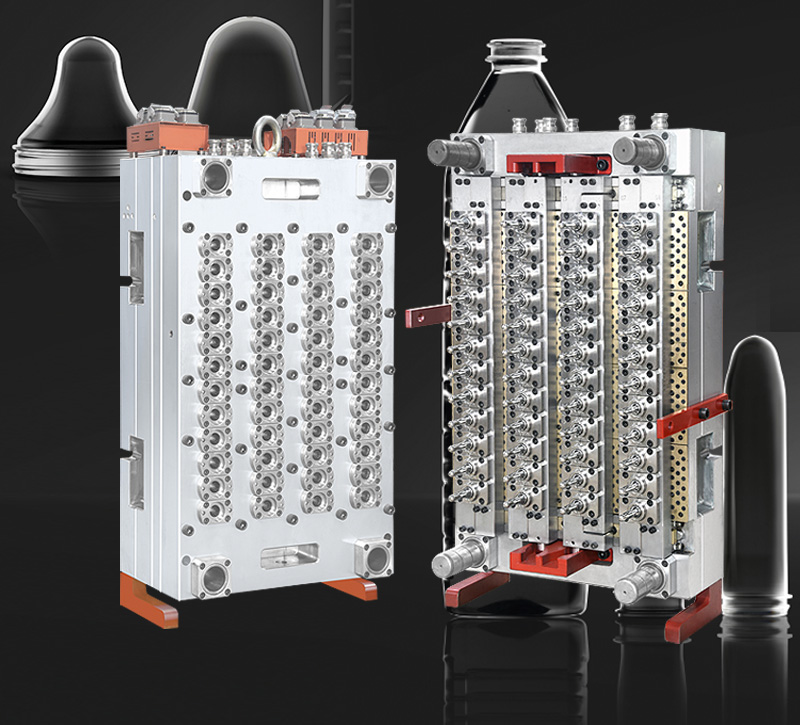

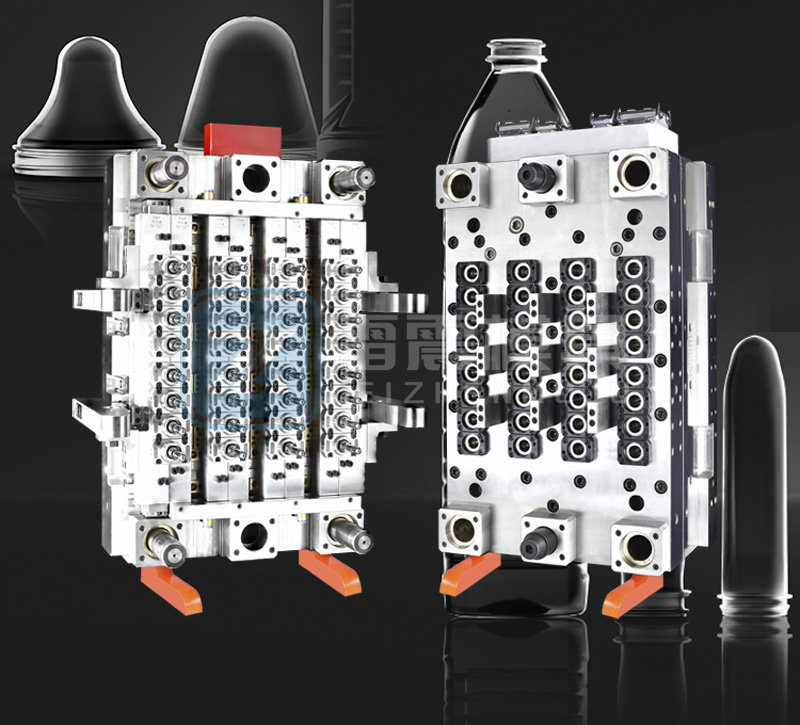

Precision Molds: The mold defines the preform's geometry. Key features include:

High-Quality Mold Steel: Corrosion-resistant and able to maintain a high polish for clarity.

Efficient Cooling Channels: Designed for uniform and rapid heat removal.

Vacuum Venting: Prevents trapped air from causing burn marks or short shots.

Auxiliary Equipment:

Dehumidifying Dryers: Non-negotiable for achieving the required moisture levels.

Chillers: Provide precise temperature control for the mold cooling water.

Automation (Robots): Ensure consistent, gentle handling and maximize uptime.

Critical Parameters for Optimal Preform Quality

Controlling these parameters is the difference between a perfect preform and a defective one.

Melt Temperature: Too high causes degradation and IV drop; too low results in poor flow and high stress.

Mold Temperature: Critical for controlling crystallinity. The neck finish needs to be crystalline for strength (hotter mold area), while the body must remain amorphous and transparent (colder mold area).

Injection Speed and Pressure: Must be optimized to fill the mold completely without causing excessive shear or molecular orientation.

Holding Pressure and Time: Prevents backflow and compensates for material shrinkage as it cools, ensuring dimensional accuracy, especially in the neck finish.

Cooling Time: Directly impacts cycle time. Inefficient cooling is a primary bottleneck.

Troubleshooting Common PET Preform Defects

| Defect | Probable Causes | Solutions |

|---|---|---|

| Hazing / Cloudiness | Moisture in material, IV drop, contamination, improper cooling. | Ensure proper drying, check for resin degradation, clean hopper and barrel, optimize mold temperature. |

| Yellowing | Thermal degradation due to excessive melt temperature or long residence time in the barrel. | Lower melt temperature, reduce cycle time, purge the barrel. |

| Short Shots | Insufficient injection speed/pressure, low melt temp, blocked filter or nozzle. | Increase injection pressure/speed, check melt temp, inspect and clean the hot runner. |

| Splay Marks (Silver Streaks) | Moisture, material degradation, or too high injection speed causing trapped air/gas. | Dry material thoroughly, lower melt temp, reduce injection speed, improve mold venting. |

| Sticky Preforms | Insufficient cooling time, mold temperature too high. | Increase cooling time, check and lower mold temperature. |

Conclusion: Investing in the Right Solution

Manufacturing high-quality PET preforms is a sophisticated process that demands precision engineering, strict process control, and a deep understanding of PET material science. Investing in a robust PET preform molding solution—from the right machine and mold to the essential auxiliary equipment—is not an expense but a strategic move towards achieving superior product quality, high production efficiency, and long-term profitability.

By mastering the parameters and technologies outlined in this guide, you can optimize your manufacturing process and produce preforms that result in perfect, high-clarity, and strong PET bottles every time.