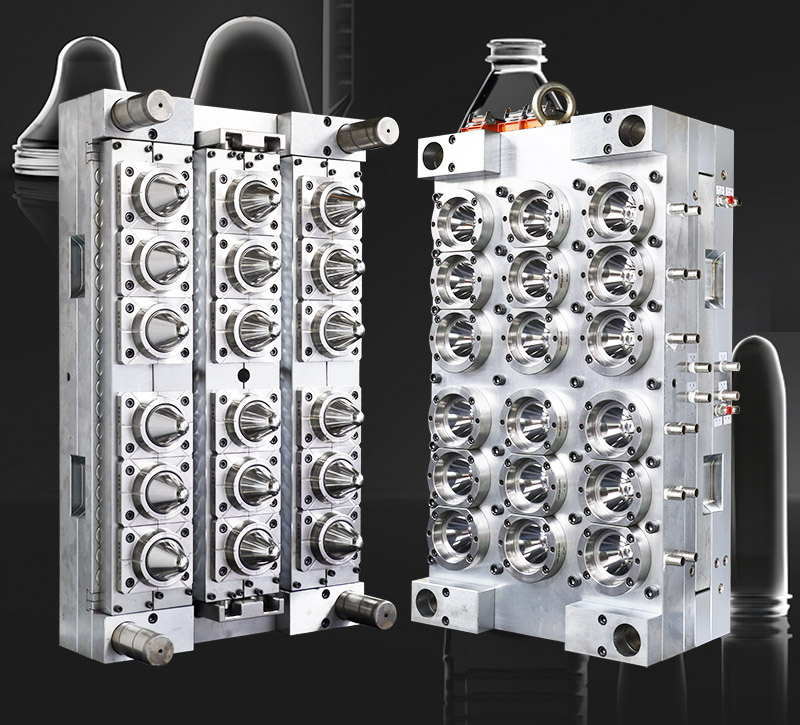

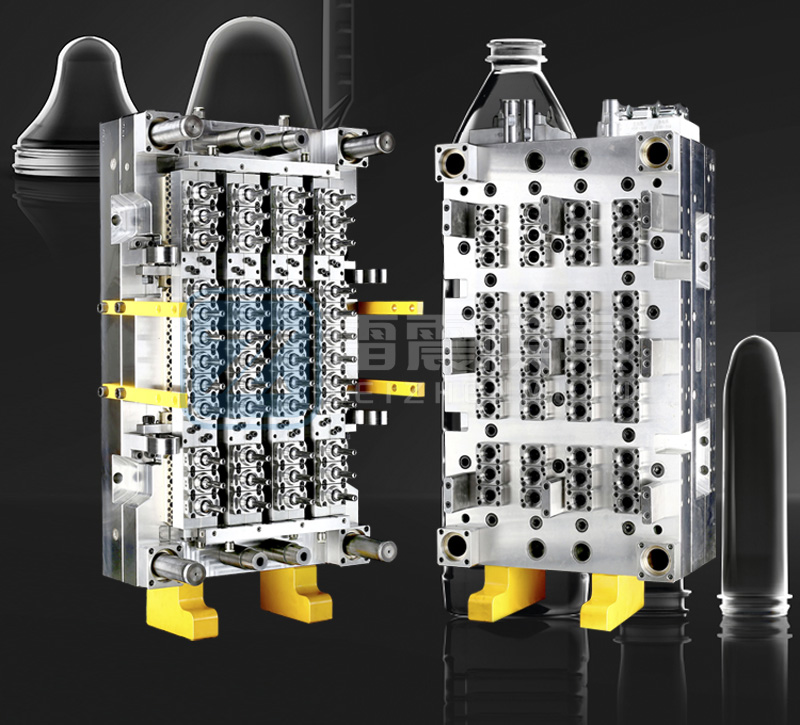

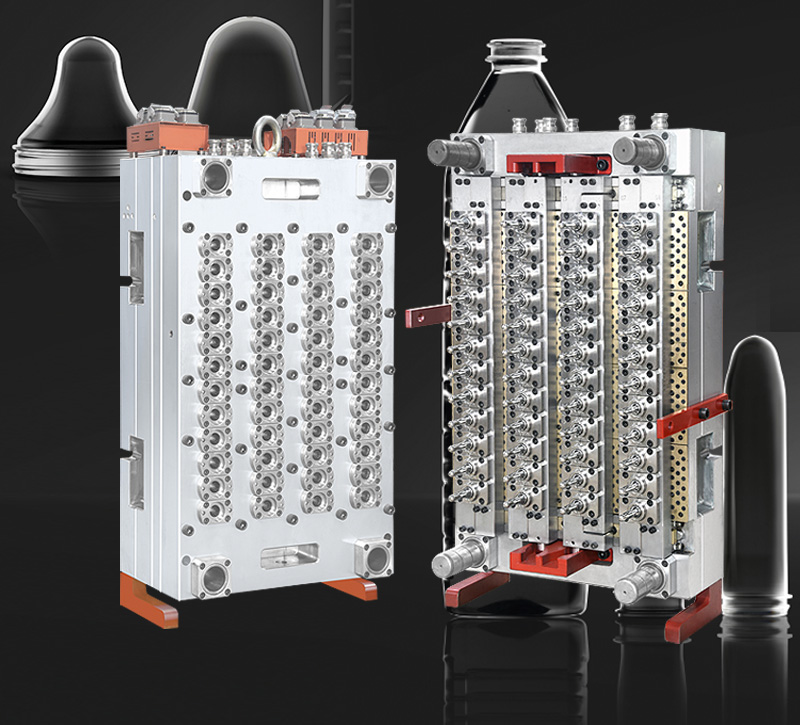

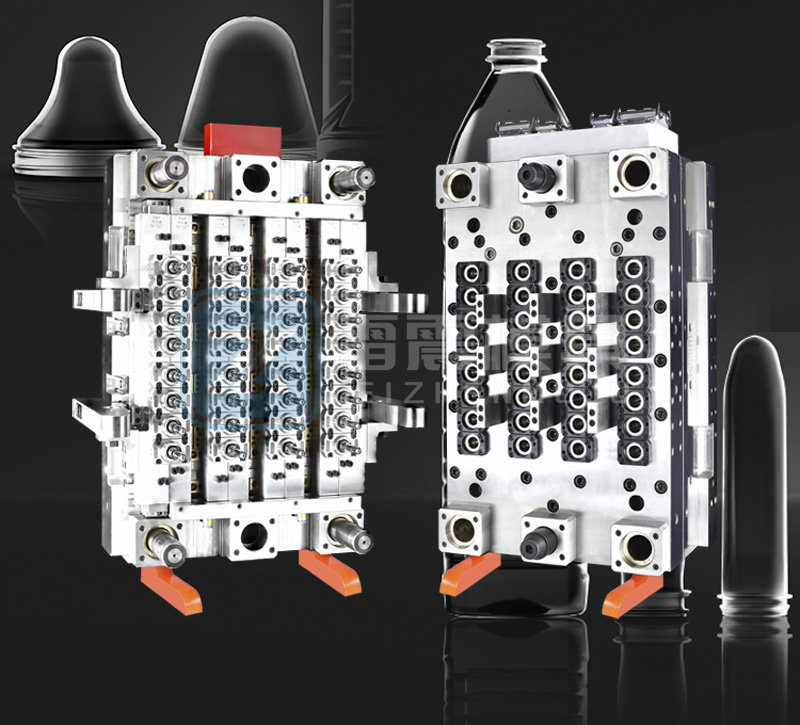

Precision Engineered for Volume: The Leizhen Mold Advantage in 24-Cavity PET Oil Preform Molds

In the competitive world of edible oil packaging, efficiency, speed, and consistency are not just goals—they are necessities. For major producers, the heart of high-output production lies in the mold that creates the PET preform. At Leizhen Mold Company, we have perfected the art and science of manufacturing high-performance 24-cavity PET preform molds specifically designed for the rigorous demands of the cooking oil industry.

The Challenge of High-Cavity Molds for Oil Packaging

Creating a 24-cavity mold is an engineering feat; creating one that runs flawlessly for producing oil preforms presents unique challenges. Oil preforms have specific requirements:

Heavier Weight: They are substantially heavier than water or carbonated soft drink (CSD) preforms.

Stress Resistance: The final bottle must withstand internal pressure from the liquid and external forces during shipping.

Clarity & Integrity: The preform must be free of defects to ensure the final bottle is clear, strong, and safe.

A standard mold often cannot meet these demands at a 24-cavity volume without succumbing to issues like inconsistent cooling, premature wear, and high maintenance downtime.

The Leizhen Method: A Blueprint for Superior Performance

Leizhen Mold Company approaches oil preform mold manufacturing with a unique philosophy that combines advanced engineering with deep industry knowledge. Our method is built on several core pillars:

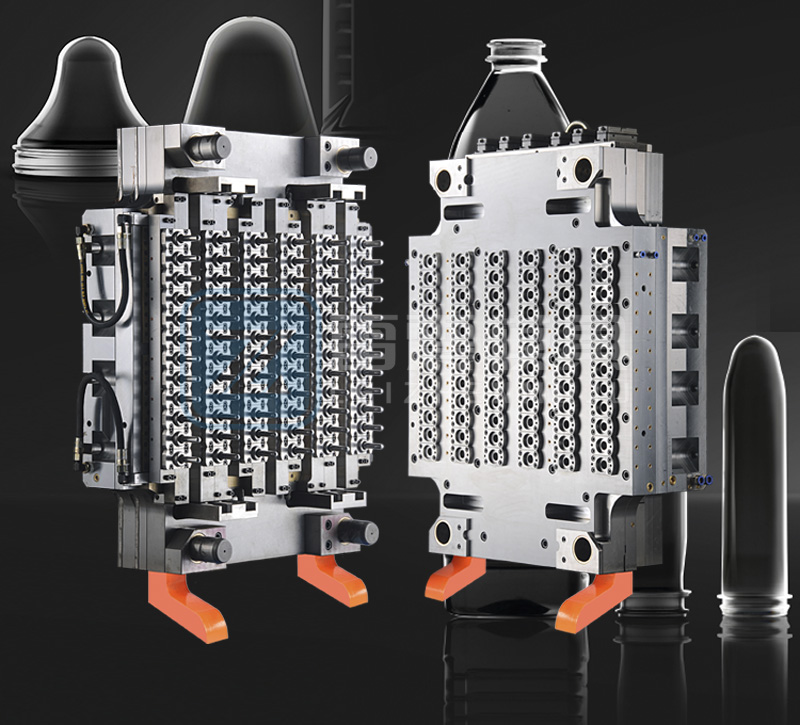

1. Advanced Thermal Management System:

The

key to a successful 24-cavity mold is uniform cooling. We utilize

sophisticated CFD (Computational Fluid Dynamics) software to design a

highly efficient cooling channel layout. This ensures every single

cavity is cooled at the exact same rate, eliminating hot spots and

guaranteeing consistent preform crystallinity, weight, and wall

thickness. This results in faster cycle times and superior bottle

clarity.

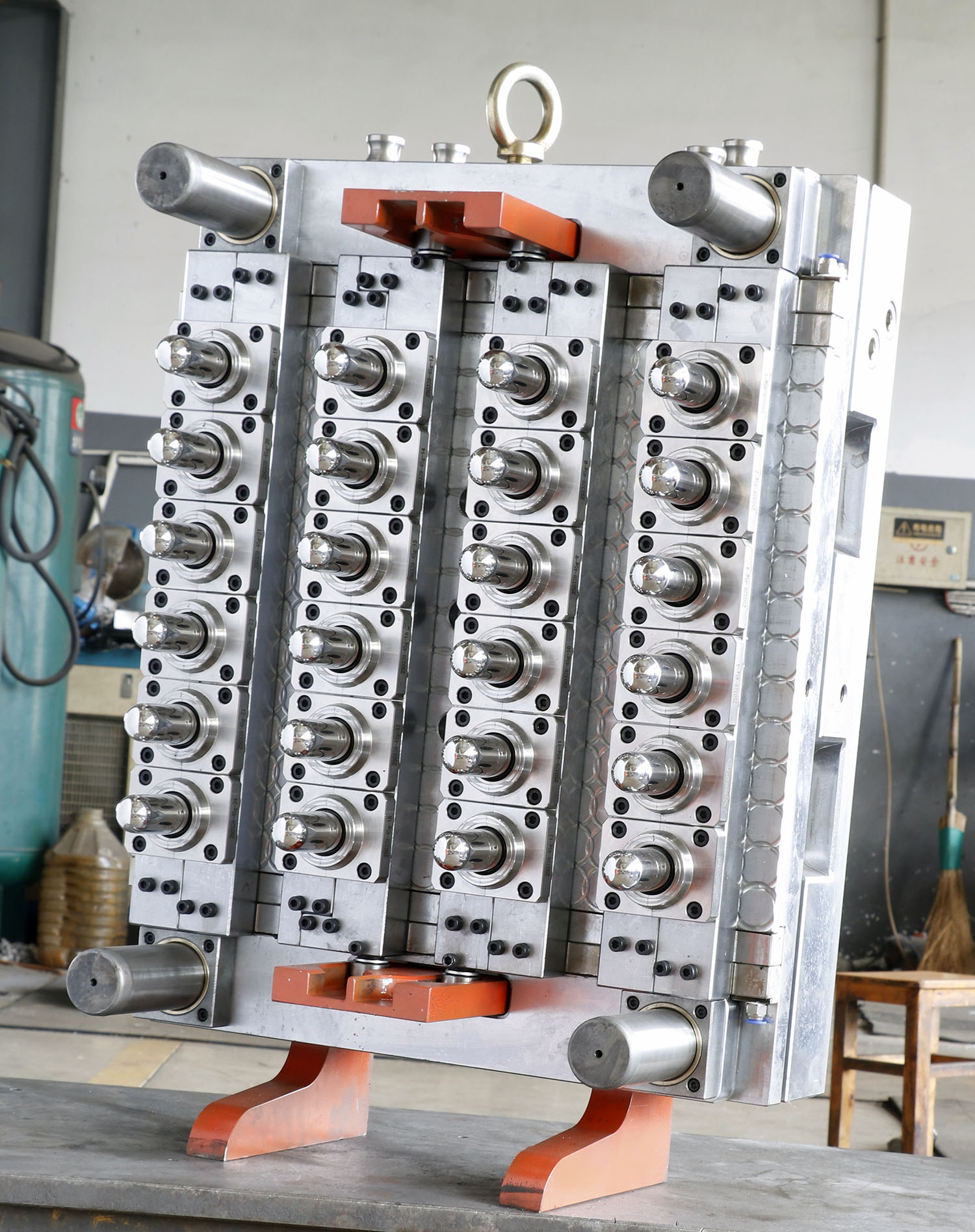

2. Unmatched Structural Rigidity:

To

handle the intense clamping forces and injection pressures required for

24 heavy-weight preforms, we construct our molds from premium,

high-tensile strength steel. Critical components are reinforced to

prevent flexing and deformation over millions of cycles, ensuring

long-term dimensional stability and a significantly extended mold

lifespan.

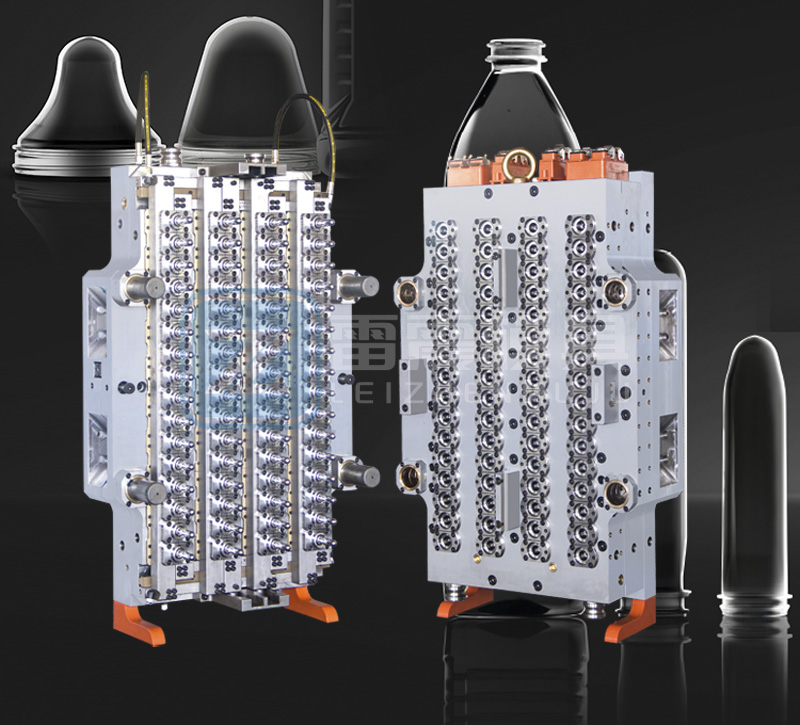

3. Specialized Surface Treatment & Corrosion Resistance:

We

understand that even trace amounts of oil or cleaning agents can affect

mold life. Our molds feature specialized surface treatments and

coatings that provide exceptional hardness and superior corrosion

resistance. This not only protects the mold but also reduces the need

for frequent maintenance and ensures a pristine preform surface finish.

4. Precision Machining for Interchangeability:

Every

component in a Leizhen 24-cavity mold is machined to micron-level

tolerances using state-of-the-art CNC and EDM equipment. This guarantees

perfect alignment and, crucially, complete interchangeability of parts.

When maintenance is required, it is fast and straightforward,

minimizing production stoppages.

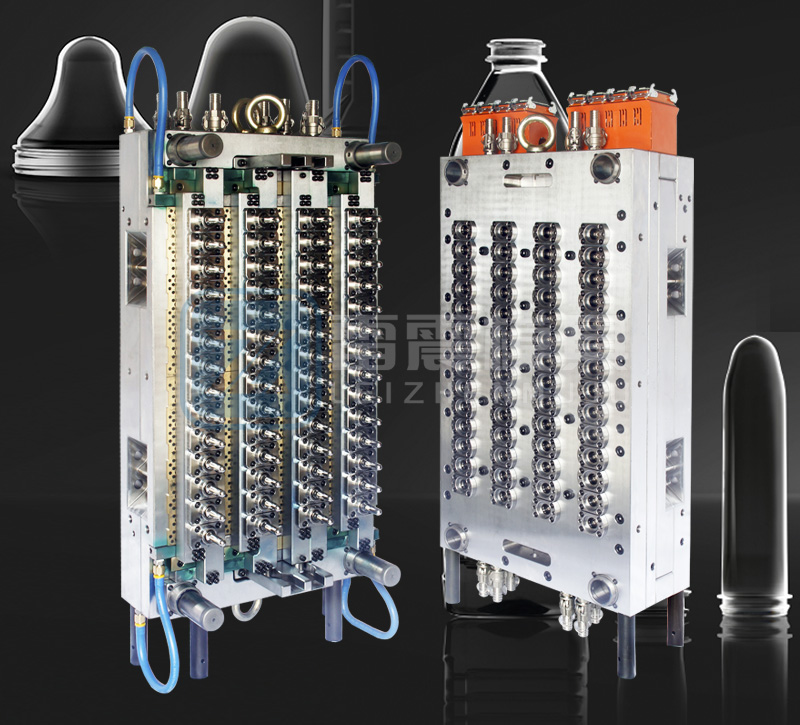

5. Expertise in Oil-Specific Preform Design:

Our

collaboration with leading oil brands gives us unparalleled insight

into preform design for various oil types and bottle shapes. We optimize

the gate design, neck finish, and body contour to ensure your preforms

stretch-blow perfectly into strong, leak-proof, and visually appealing

bottles.

Why Partner with Leizhen Mold for Your Production Needs?

Choosing a Leizhen 24-cavity PET oil preform mold is an investment in your production line's profitability. You benefit from:

Maximum Output: Achieve the highest production volumes with reduced cycle times.

Exceptional Quality: Produce consistent, high-quality preforms batch after batch.

Reduced Downtime: Our robust design and precision engineering mean reliability you can count on.

Lower Cost-Per-Unit: Increased efficiency, speed, and durability translate directly to a lower cost per preform over the mold's lifetime.

At Leizhen Mold Company, we don't just build molds; we build reliable, high-performance production solutions. If your goal is to dominate the edible oil market with uncompromising quality and efficiency, our 24-cavity PET oil preform mold is the engine you need.

Contact us today to discuss your project and discover the Leizhen difference.