Precision Engineered Bottle Preform & Cap Molds | Your Trusted Manufacturing Partner

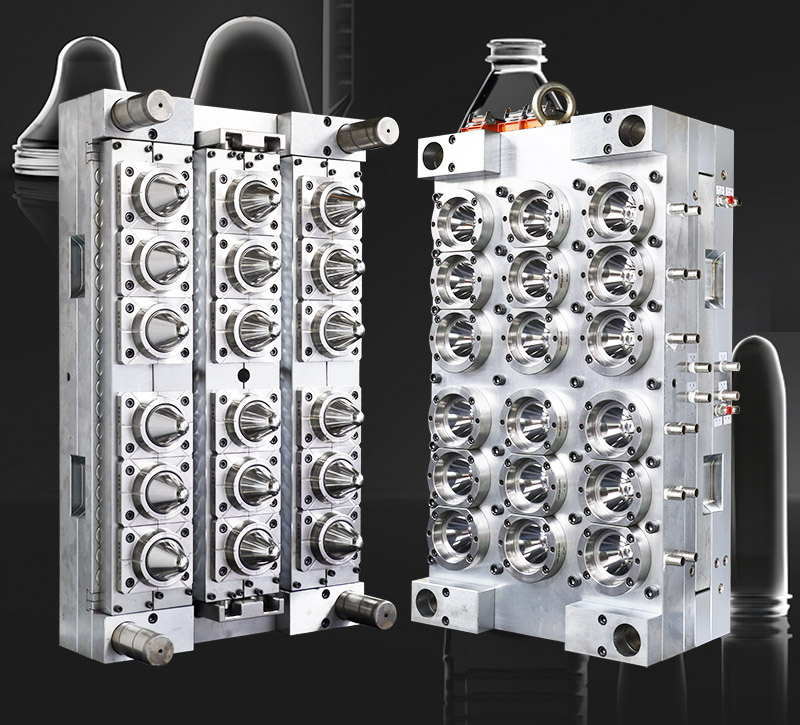

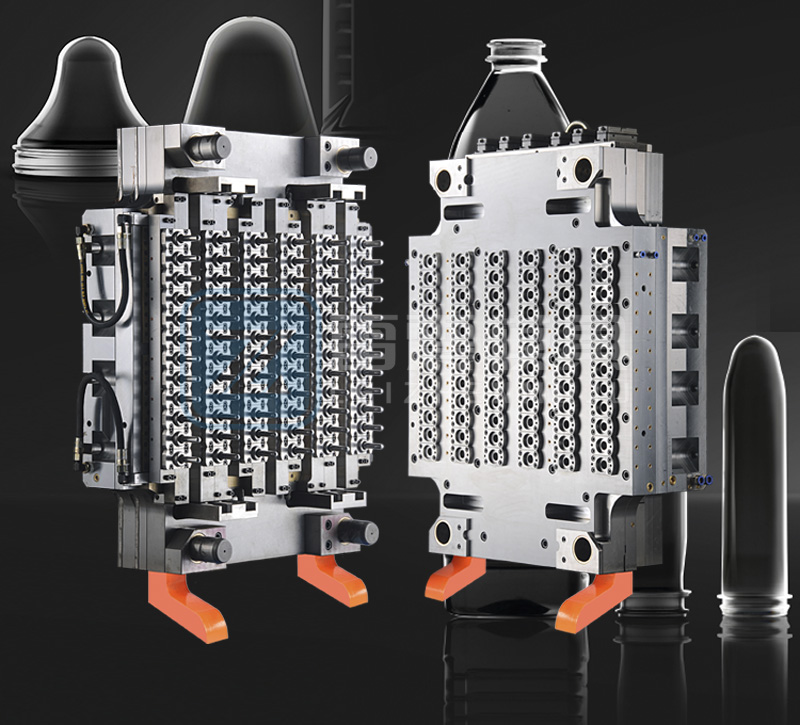

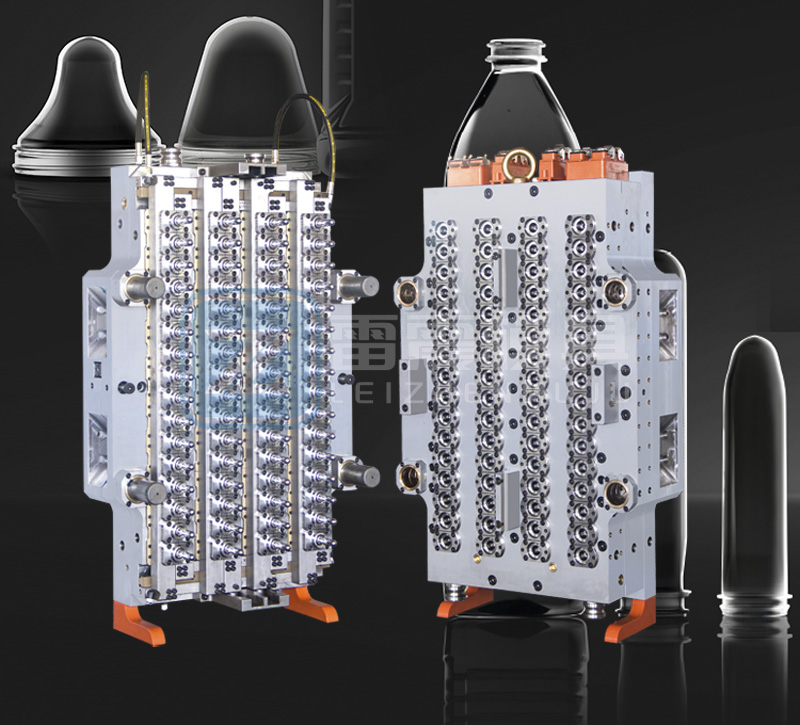

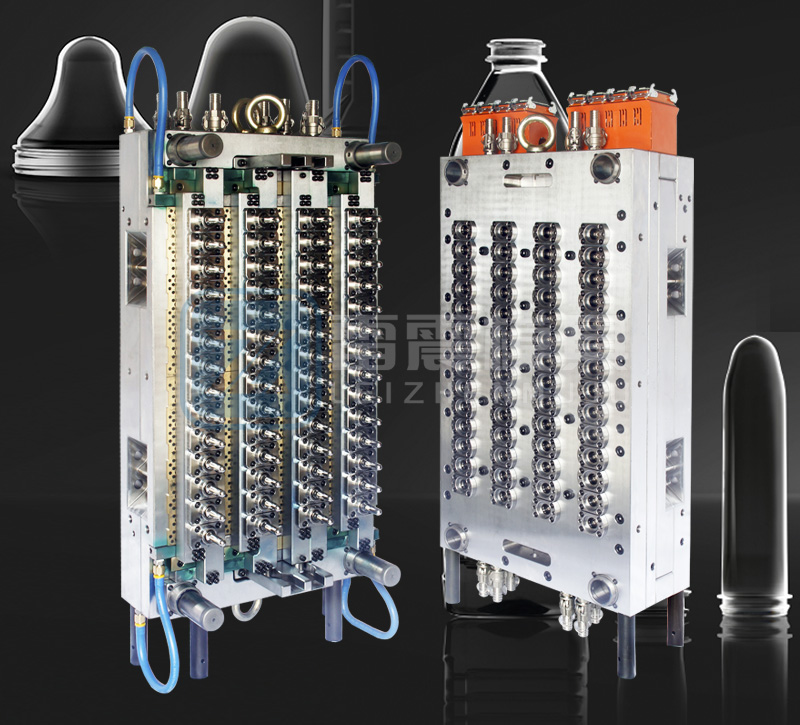

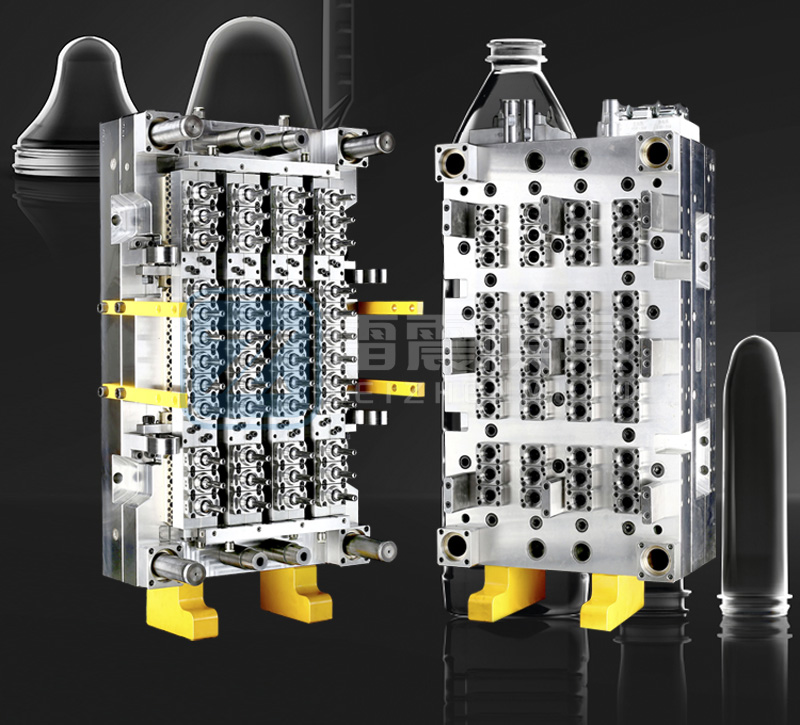

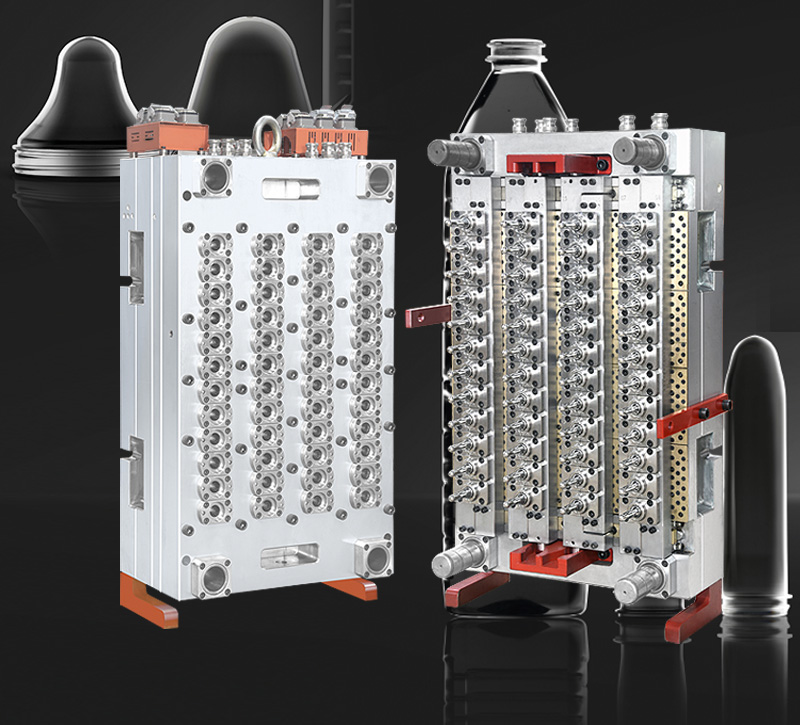

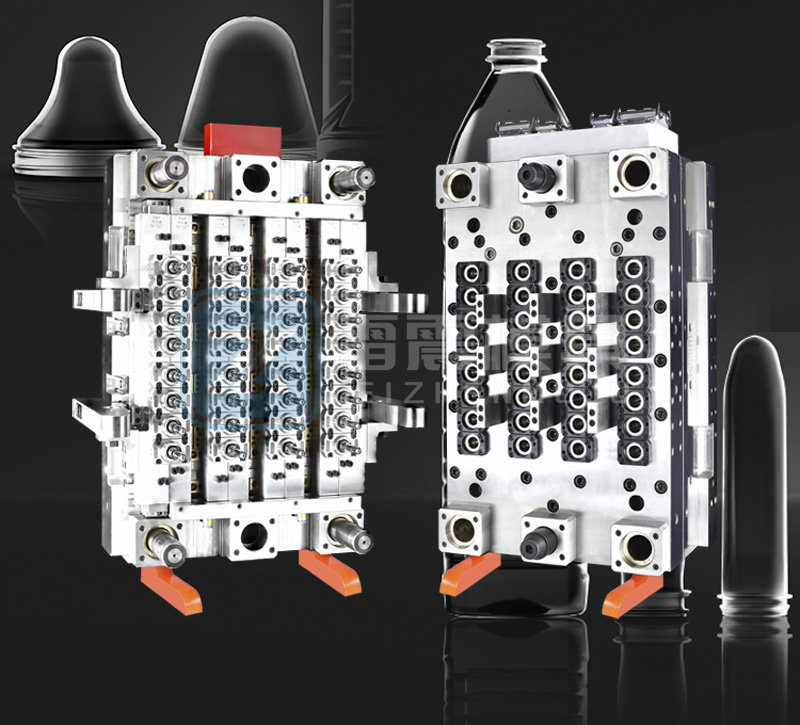

End-to-End Service: From initial concept and CAD design to precision machining, assembly, testing, and after-sales support, we manage your project seamlessly. Advanced Manufacturing: Our workshop is equipped with modern machinery, including 5-axis CNC machines, high-speed CNC, and wire-cutting equipment, guaranteeing tolerances within ±0.005mm. Material Science Expertise: We recommend and use the best grade of stainless steels and alloy steels (e.g., H13, S136) for superior wear resistance, corrosion resistance, and longevity. Customization is Key: We don't believe in one-size-fits-all. Our engineering team works closely with you to develop custom injection molds tailored to your specific preform design, cap design, production volume, and resin type. Focus on Efficiency: Our mold designs prioritize rapid cooling and efficient cycling to maximize your output. Quick-release systems and standardized components simplify maintenance. Global Export Experience: We have a proven track record of delivering molds safely and on time to clients across Europe, North America, South America, and Asia. Our Product Range Includes: Bottle Preform Molds (Single-cavity & Multi-cavity) PET Preform Injection Molds Plastic Cap Molds (for PCO-1810, 1881, 38mm, etc.) Water Bottle Cap Molds Closure Molds for Beverage, Food, Pharmaceutical, and Chemical Industries Injection Stretch Blow Molds (ISBM) Custom Plastic Injection Molds

Partner with Us for Your Next Project Whether you are launching a new product or looking to upgrade your existing production line, a high-quality mold is your most critical investment. Let [Your Company Name] be the force behind your packaging success. Contact us today to discuss your technical requirements and receive a competitive quotation.