Taizhou Leizhen Molds Co., Ltd. - Your Premier Partner for High-Performance PET Preform Molds and Cap Molds

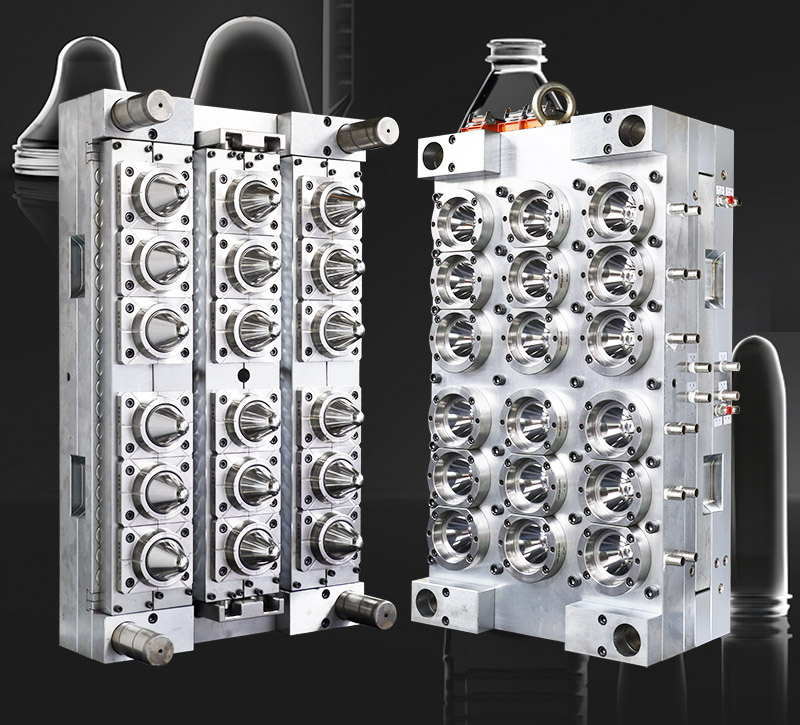

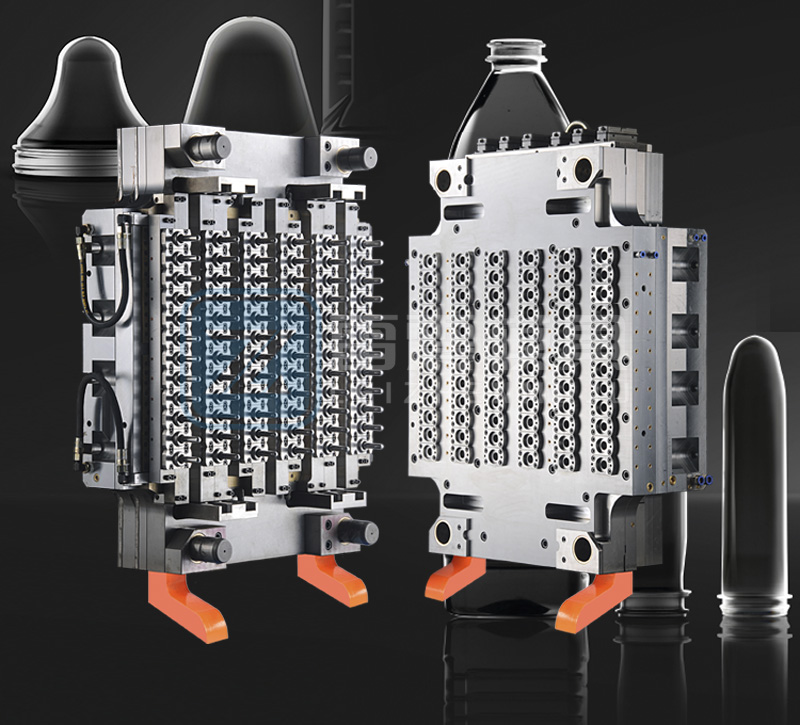

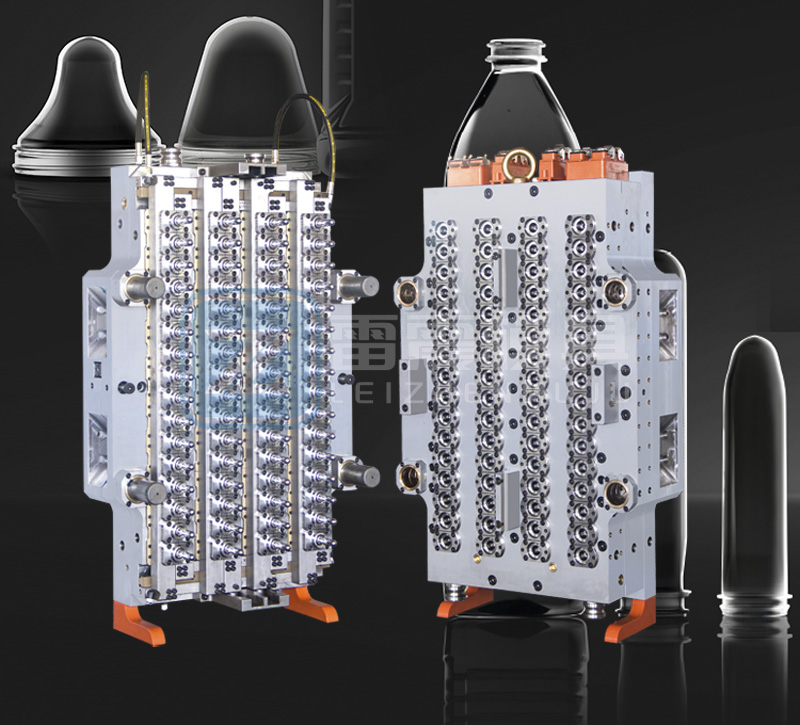

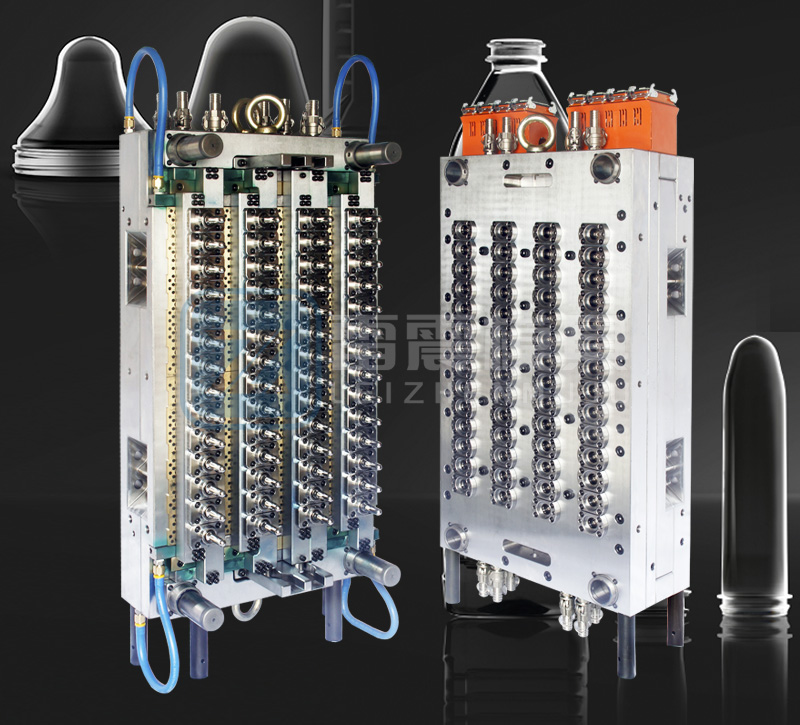

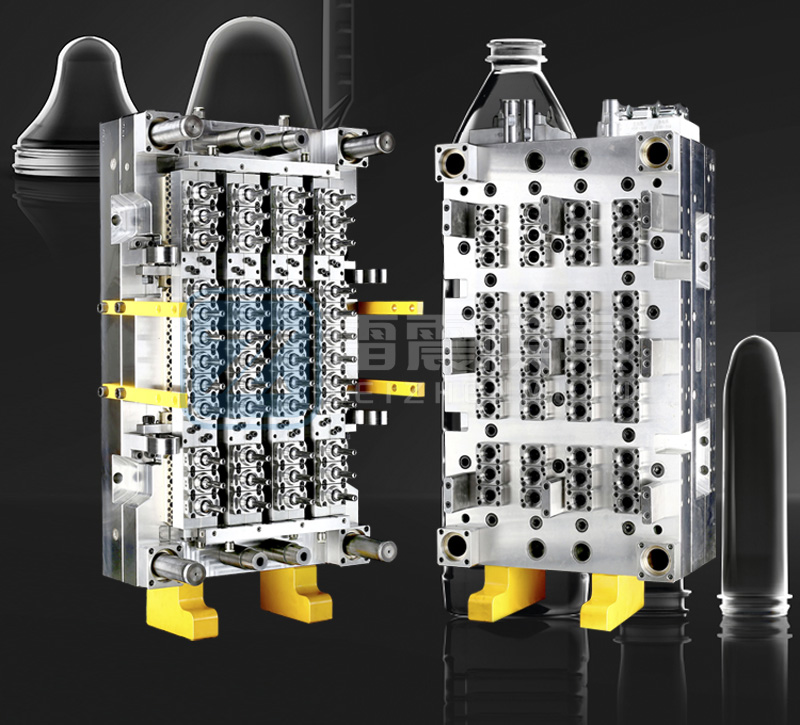

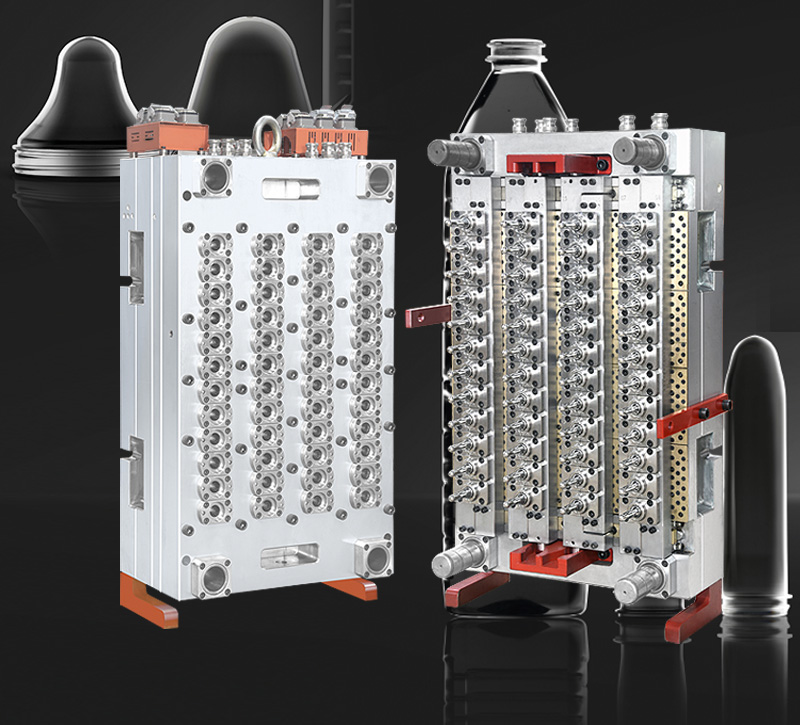

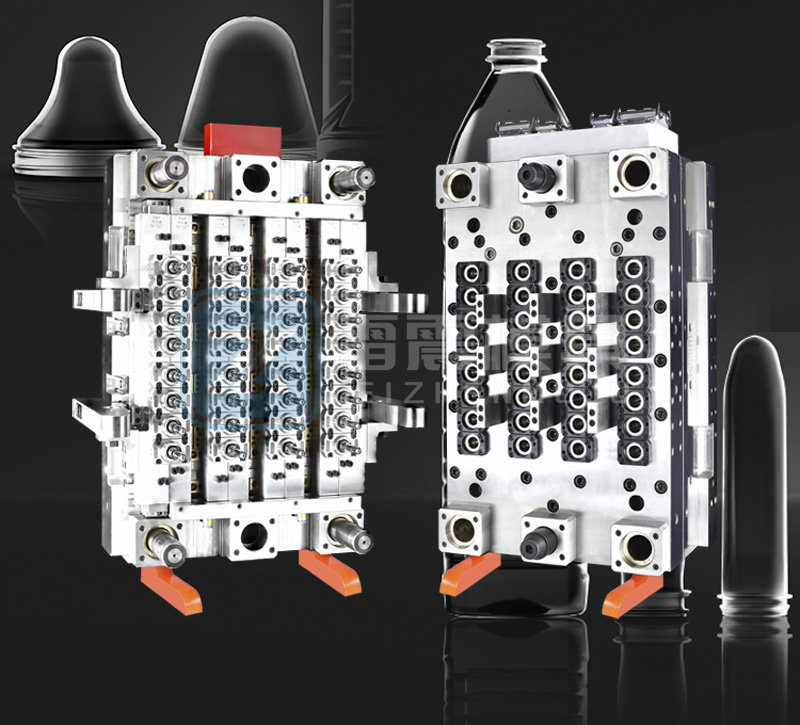

Unmatched Expertise in PET Preform Molds: Our core competency lies in designing and manufacturing high-cavitation injection molds for PET preforms. We understand the critical parameters for achieving excellent material distribution, clarity, and barrier properties in the final preform. Our preform molds are engineered for maximum output and longevity, ensuring your production lines run smoothly 24/7. Whether you need a 48-cavity or a 144-cavity mold, we deliver precision that translates directly to your bottom line. Comprehensive Range of Cap Molds: A perfect bottle deserves a perfect cap. Leizhen Molds produces robust and intricate cap molds for various applications, including water bottles, beverage bottles, cooking oil containers, and pharmaceutical packaging. We specialize in molds for PCO 1881 caps, PCO 1810 caps, and other standard and custom closures. Our focus is on creating molds that produce caps with consistent thread quality, reliable tamper-evident bands, and smooth de-molding. Integrated Solutions: From Mold to Machine Compatibility: We offer more than just a mold; we provide a complete solution. Our team has extensive experience ensuring our injection molds and blow molds work in perfect harmony with leading injection molding machines. This systems-level approach minimizes downtime and optimizes the entire production process for our clients. Quality as Our Foundation: At Leizhen Molds, quality is ingrained in our process. We utilize premium mold steels (such as H13, S136) and advanced machining centers, including CNC, EDM, and wire-cutting machines. Every mold undergoes a rigorous inspection process to guarantee dimensional accuracy, superior surface finish, and flawless functionality. We are committed to delivering durable plastic molds that withstand high-volume production cycles. Customer-Centric Partnership: We view every project as a partnership. From the initial design consultation to after-sales support, our engineering team works closely with you to understand your specific needs and challenges. We provide professional technical advice and custom mold design services to help you achieve your production goals.