Premier Manufacturer of High-Performance PET Preform Molds and Cap Molds

Water Bottle Molds: Producing crystal-clear, high-strength preforms. Carbonated Soft Drink (CSD) Molds: Engineered to withstand internal pressure with superior material distribution. Juice and Edible Oil Bottle Molds: Designed for compatibility with various contents and ensuring product integrity. Custom Closure Molds: For a variety of caps, from simple PCO caps to sports caps and dispensing closures.

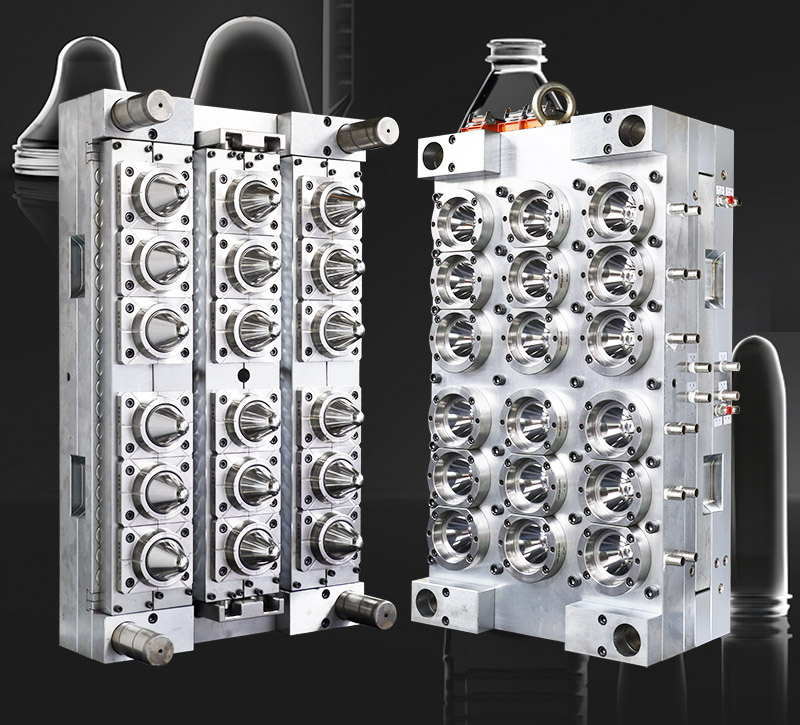

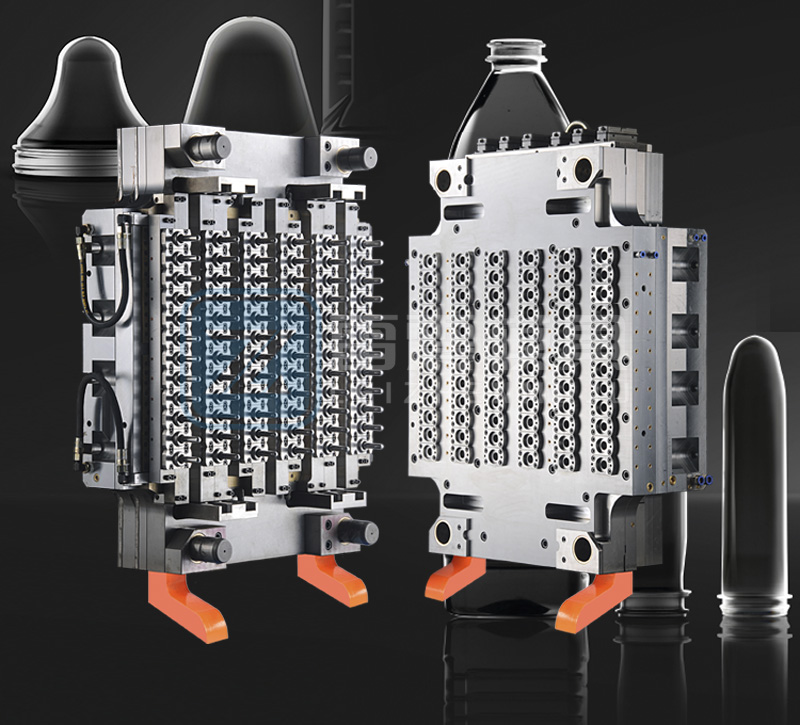

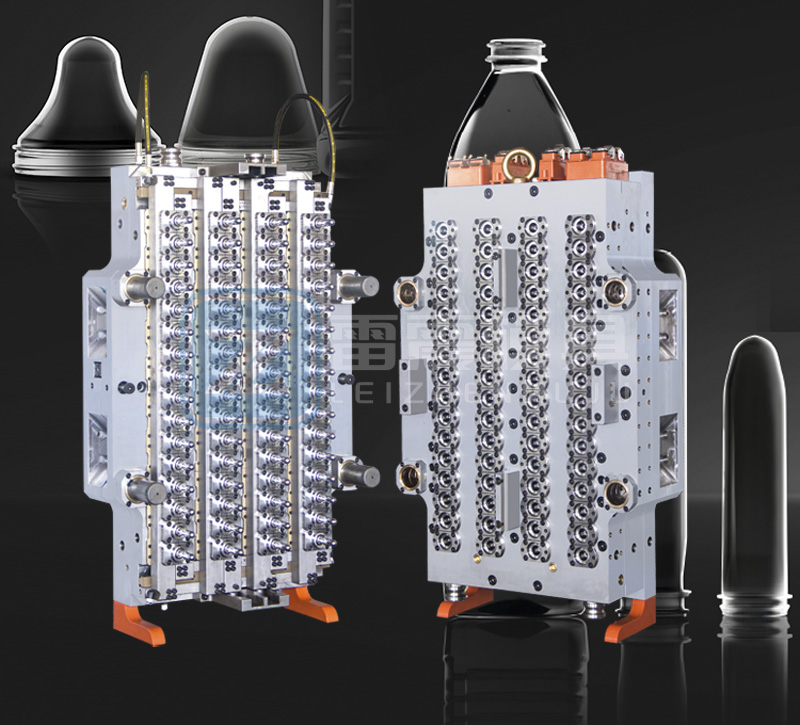

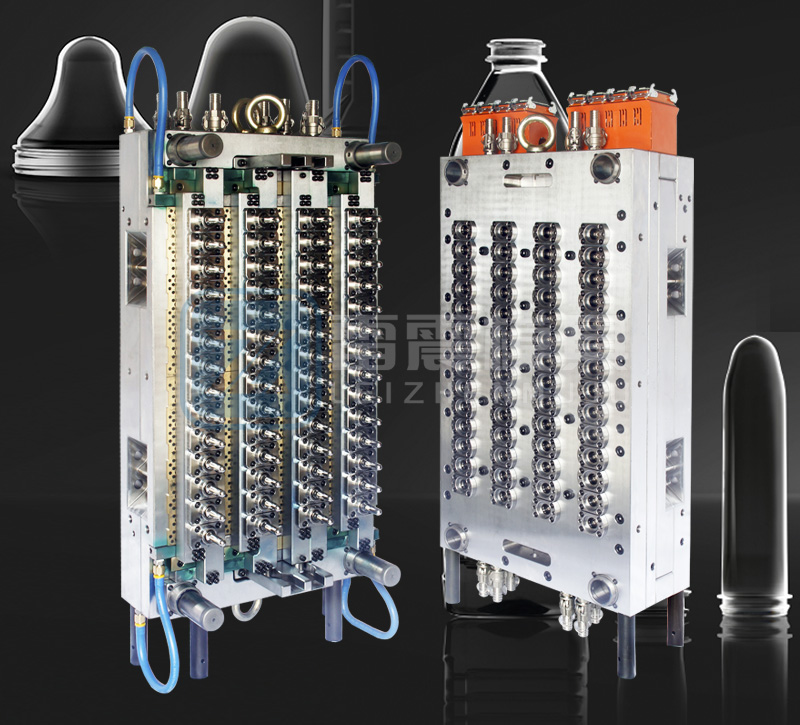

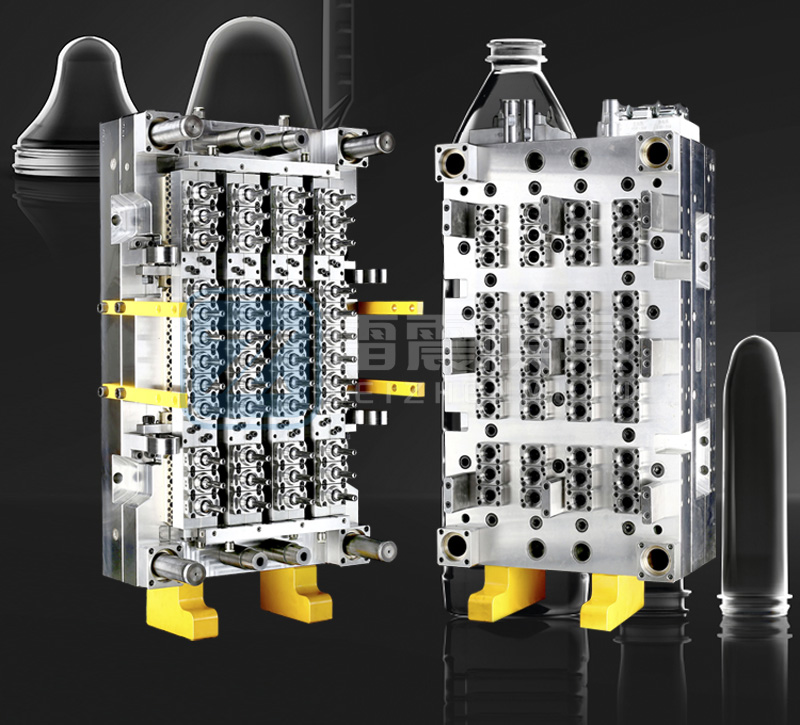

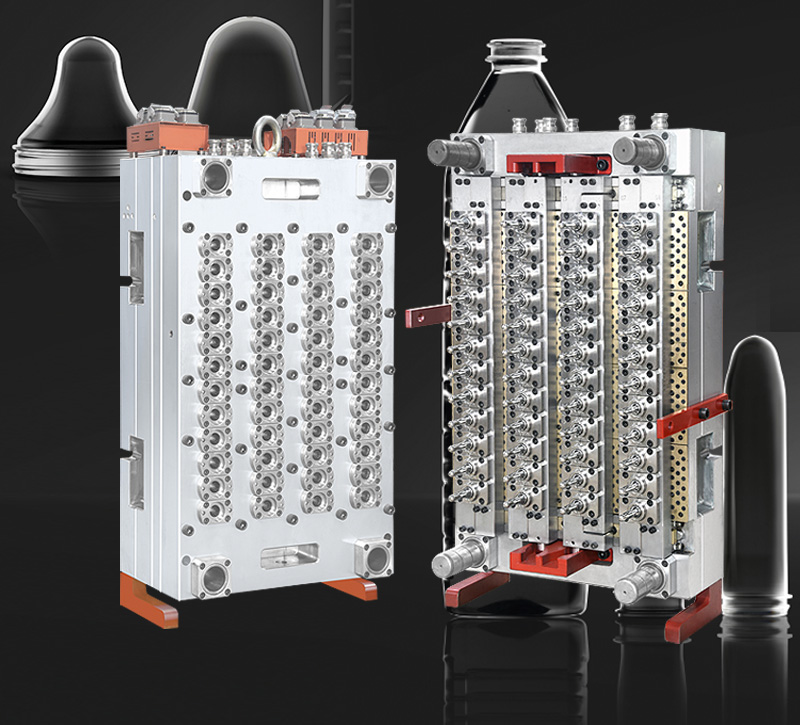

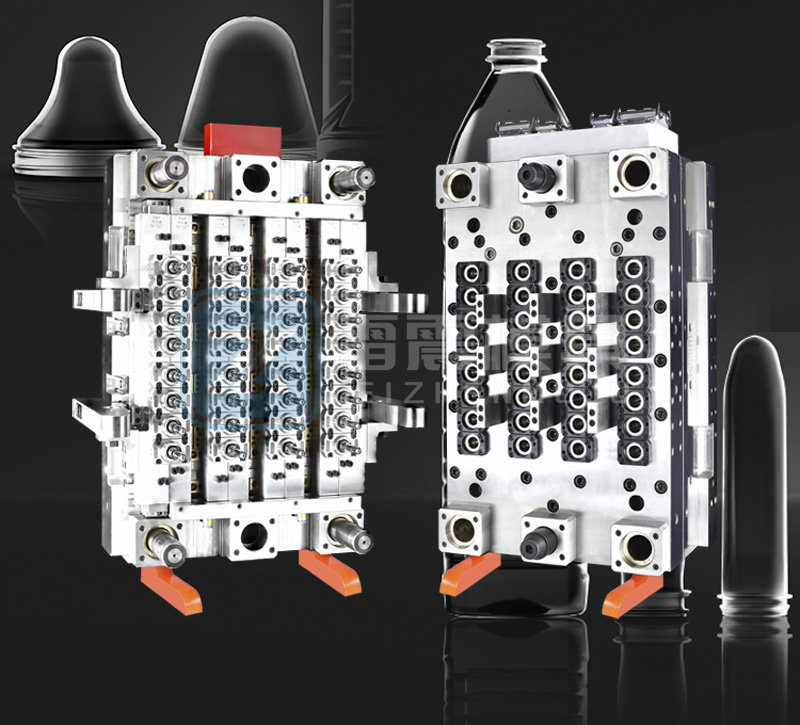

Unmatched Preform Quality and Consistency: The quality of the final bottle starts with the preform. Our PET preform molds are engineered to produce preforms with exceptional consistency in wall thickness, superior internal and surface finish, and optimal stress distribution. This precision is critical for achieving high clarity, excellent barrier properties, and maximum top-load strength in the blown container, directly reducing your rejection rates and material usage. Maximized Productivity with High-Cavitation and Robust Systems: Time is money. Our designs focus on maximizing your output. We specialize in high cavitation molds (e.g., 48-cavity, 72-cavity, and beyond) integrated with world-class hot runner systems. We have extensive experience collaborating with leading hot runner brands like Husky and Mold-Masters, ensuring seamless melt delivery, balanced filling, and minimal pressure drop. This results in shorter cycle times and significantly higher production volumes for your injection molding machines. Exceptional Durability and Long Service Life: Downtime is the enemy of profitability. Leizhen molds are built to last. We construct our molds from premium-grade steels such as SS420, H13, and S136, selected for their exceptional hardness, corrosion resistance, and polishing capabilities. Combined with state-of-the-art heat treatment processes, our molds exhibit extraordinary resistance to wear and abrasion, guaranteeing a long and productive mold lifespan even under the most demanding 24/7 production schedules, thereby lowering your cost-per-unit over time. Optimized for Efficiency: Cooling and Maintenance: Efficiency is engineered into every detail. Our molds feature optimally designed cooling channel layouts that ensure rapid and uniform heat exchange, which is fundamental to achieving fast cycle times. Furthermore, we design our injection molds for ease of maintenance, with standardized components and accessible wear parts, minimizing your maintenance time and costs.

Consultation & Design: We collaborate closely with you to understand your specific needs, performing CAE mold flow analysis (using software like Moldflow) to simulate and optimize the filling, cooling, and warpage of the preform or cap before cutting the first piece of steel. Precision Manufacturing: Our workshop is equipped with advanced CNC machining centers, EDM machines, and deep-hole drilling equipment, operated by our team of skilled technicians. Stringent Testing & Quality Control: Every mold undergoes a comprehensive testing procedure at our facility. We produce sample preforms/caps and provide detailed inspection reports to ensure the mold performs exactly as specified. After-Sales Support: Our relationship doesn't end at delivery. We provide comprehensive technical support, detailed maintenance documentation, and a reliable supply of spare parts to keep your production running smoothly.