With more than 10 years of experience in the manufacture of multi-cavity preform molds, the technology in the field of preform molds is mature. Can meet the requirements of the market and customers.

Leizhen Mold is located in Huangyan, Taizhou, the "Hometown of Molds" in China. Focusing on the design, development, and manufacture of PET tube embryo molds, PET bottle embryo molds, PET molds, bottle cap molds, plastic packaging bottle molds, plastic bottle molds, and plastic molds, it is a manufacturer of automatic bottle embryo moulds. The location of our factory is superior, with the port in the east, National Highway 104 in the west, the airport in the south, and the expressway in the north, with convenient transportation. Our factory has mold engineers with many years of experience, and adopts CAD/CAM/CAE computer systems and precision processing equipment to produce various PET molds (such as: needle valve type, shear-free intersection, independent self-locking, adjustable eccentricity and other new PET molds) , high concentricity, guarantee that all cavities and cores can be interchanged. And the price is reasonable, the delivery is timely, and has been trusted and praised by customers. Our company always adheres to the tenet of "survival by quality, development by service", and is committed to continuous innovation, and serves our customers wholeheartedly

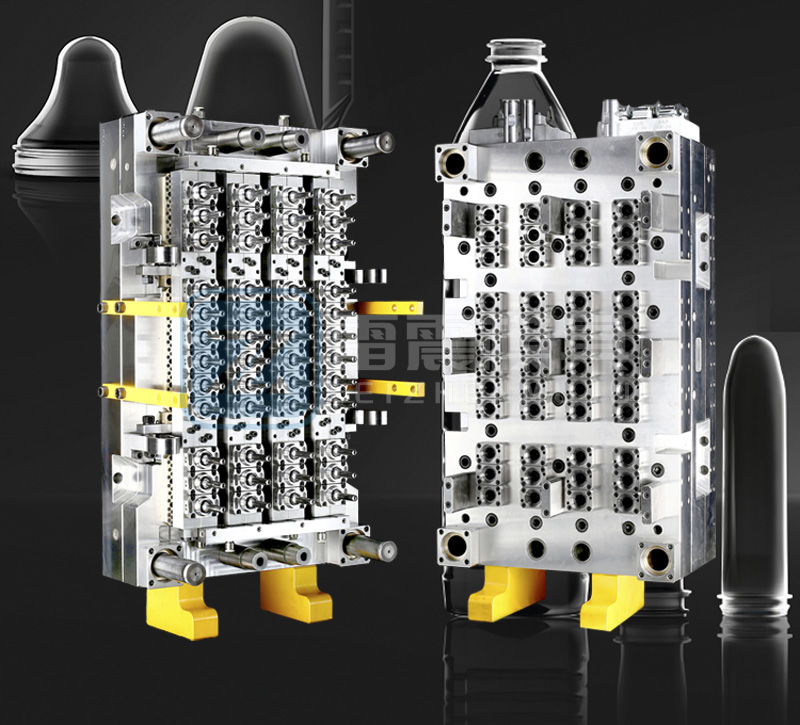

Leizhen Mold Department produces multi-cavity PET preform injection molds every year, ranging from 48 cavities to 72 cavities. After years of experience accumulation and technical precipitation, Leizhen Mold makes PET tube embryo molds with high speed and high blowing rate. High, durable, easy maintenance and many other advantages.