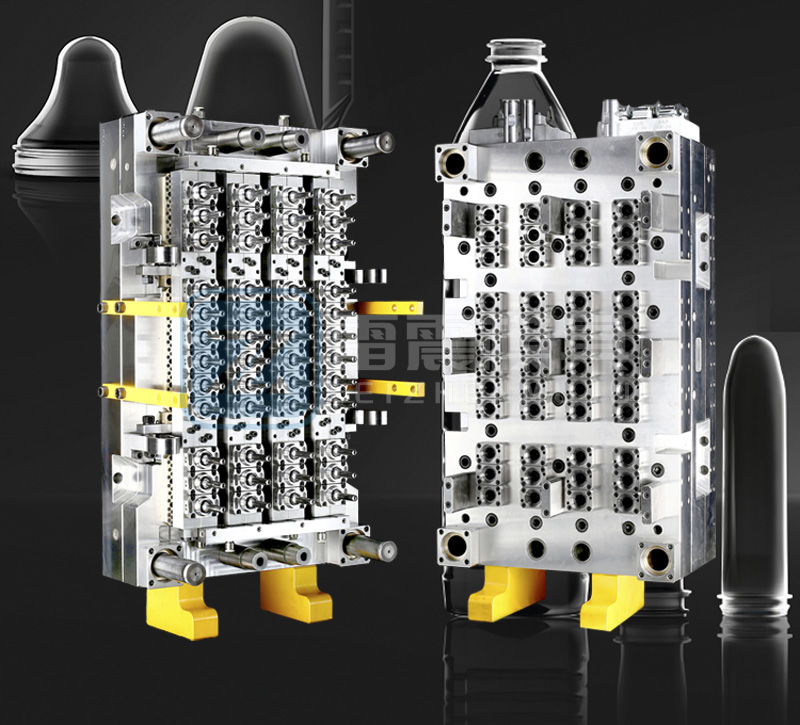

Produce high-quality preforms, use corrosion-resistant steel plates, and optimize preform production. Our molds have a long lifespan. The mold design ensures quick and easy maintenance. Our molds are easy to use and regular maintenance work can be carried out directly on the machine in the shortest possible time. Mold accessories are easy to replace, and different preforms can be produced on the same mold. Rugged mold parts guarantee mold life and minimize maintenance. We can produce PET preform mold, PET tube preform mold, 72-cavity preform mold, 48-cavity preform mold, 32-cavity preform mold, 24-cavity preform mold, 16-cavity preform mold, 12-cavity preform mold, 8 Cavity preform mold, 4-cavity preform mold, 72-cavity tube blank mold, 48-cavity tube blank mold, 32-cavity tube blank mold, 24-cavity tube blank mold, 16-cavity tube blank mold, 12-cavity tube blank mold, 8-cavity tube blank Blank mold, 4-cavity tube blank mold.

1: The number of preform (preform) mold cavities ranges from 1 to 96 cavities

2: The preform (preform) mold adopts CAD software, and the bottle is designed according to the bottle Preform shape ensures the molding quality of the bottle.

3: The preform mold (bottle embryo) mold thread material is made of imported nitrided steel, manufactured according to international standards, with high hardness, each thread is ventilated, and has a long service life without deformation.

4: Preform (bottle embryo) mold core, cavity is made of corrosion-resistant steel, durable.

5: The preform (bottle embryo) mold adopts advanced hot runner design, so that each cavity can be independently temperature controlled, heated, and the temperature is uniform.

6: Free-shear gate preform (preform) mold, saving labor and raw materials.

7: The temperature of the hot runner nozzle is controlled separately. (Advantages of individual control to solve problems in the production process, such as white bottom, drawing).

8: Needle valve self-locking preform (preform) mold: each core, cavity, independent double self-locking, adjustable eccentricity, reduce eccentricity, ensure product concentricity, high precision. The mold has a long service life.

9: Support sample and drawing processing, provide new product development, and provide one-stop service for injection molding processing!