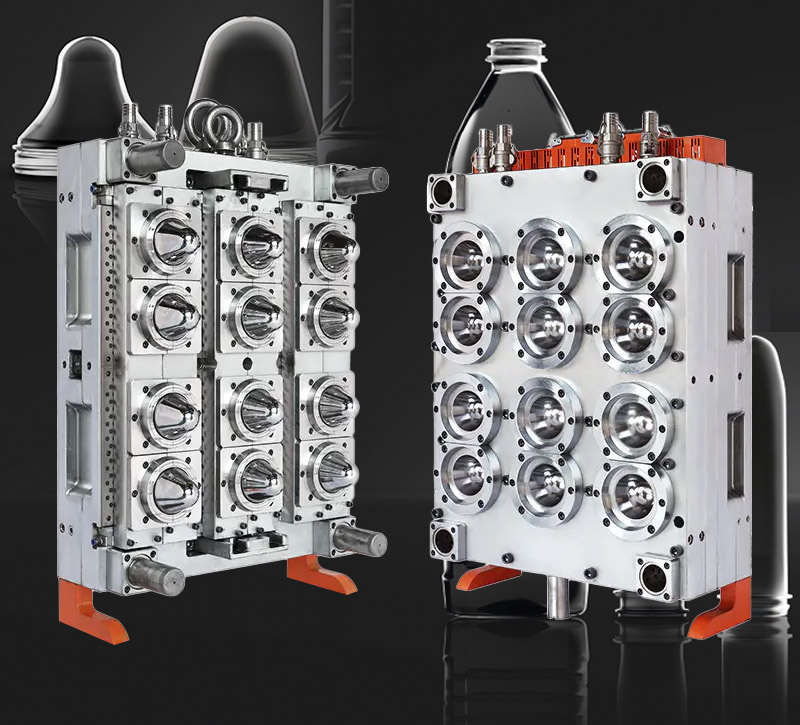

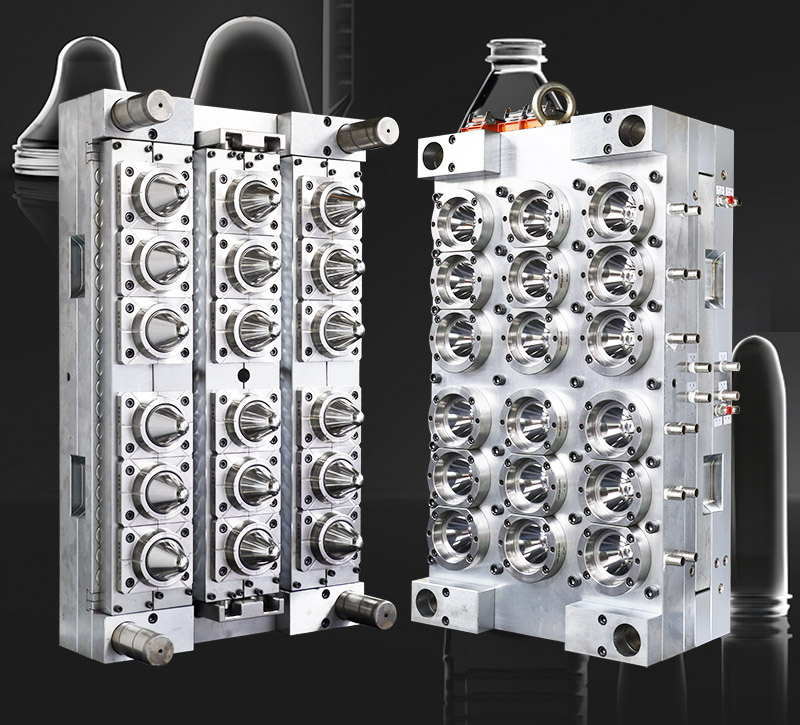

120mm 70g wide mouth preform mould

This mould is used to produce 120mm 70g wide mouth preform.It has self-lock and lock way,The cavity is 12. It adopts high quality material from Jiangxi .And it operates with the temperature controller from Ningbo and the core & cavity from S 136 ,The copper nozzle is made from imported Germany(refined Cu) used in this mould. Heat plate is P 20 and heater strip is also import material from Germany. Insulation mat is Dupont made in America,Clinder cap and valve pin are punch by Japan.

This mould is made of 4Cr13 steel,hardness up to HRC48-49, High temperature resistant, Advantageous price and quality. Professional manufacturer mould manufacturer in China, provide the wide range of plastic molding design and technical service overnight!

This mould is our new mold,with fast and high-quality making.It has a same structure as our mould but with a better inner wall design.120mm preform moulds,high quality,preform weight from 70g.

We are a professional production of mold,Spare Parts and Mould Processing≤≥20 years.We have our own sales team,technical team, provide the best solution for you!

| Lock way | Double self-lock |

| Preform neck | 120mm |

| Preform weight | 70g |

| Core&cavity | S136 |

| Cavity No. | 12 |

| Copper nozzle | Material from Jiangxi |

| Heating plate | P20 |

| Heater strip | Import Germany |

| Sprue Runner | H13 |

| Clinder,clinder cap,piston | AL |

| Valve pin | Punch(from Japan) |

| Insulation mat(cap) | Dupont( from America) |

| Copper plate | Material from Jiangsu |

| Heating ring | Material from Guangdong |

| Reducing elbow | Material from Guangdong |

| Temperature controller | Material from Ningbo,Japan |

| Mould plate | 4Cr13/ P20 |

| Lifetime | At least 2million Shots |

| Hardness | HRC45-HRC48 |

| Slide block | P20 |

| Heat block | P20 |

| Exporter country standard voltage | 380V/3PH/50HZ |

| Packing | 1.Outside package:Standard wooden cases;2.Inner package: Stretch waterproof film & Each Mold painted anti-rust oil. |

| Delivery time | Within 40 working days after prepayment |

| Term of Payment | 30% T/T deposit,70% T/T before delivery after confirmation of testing samples. |

| Guarantee | 1Year after-sale service.If the mould is damaged without artifical damage,Engineers available to service machinery overseas |

| Test parameters and videos will be sent when testing the mould. | |

Premium Wide-Mouth Preform Mold Manufacturer | ISO-Certified Solutions for Global Brands

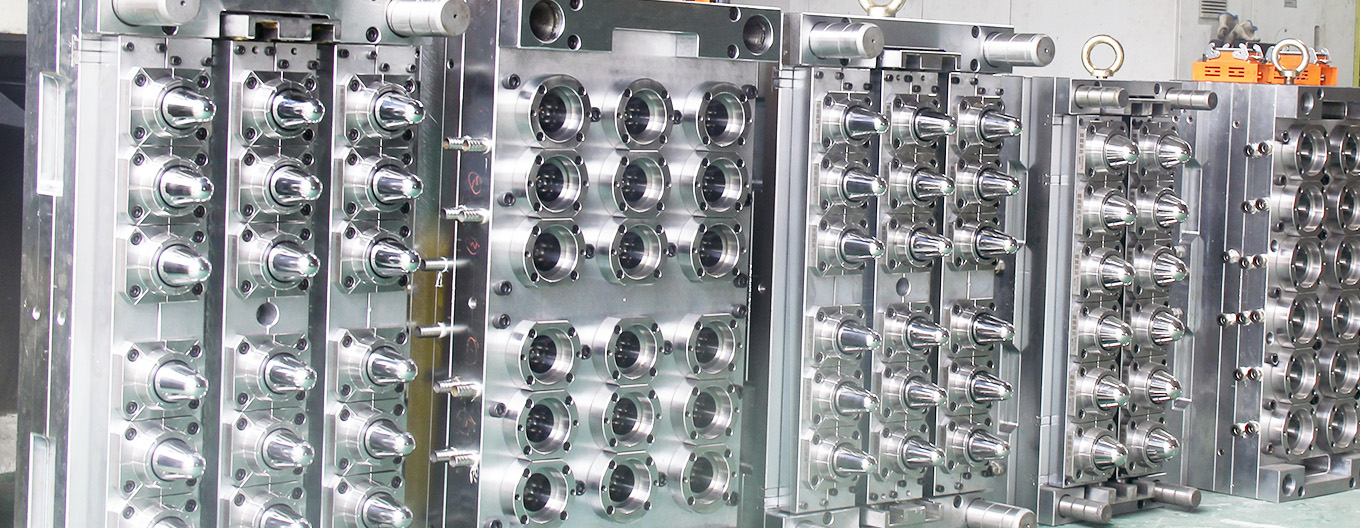

As a specialized wide-mouth preform mold manufacturer, we engineer precision molds for PET jars, bottles, and containers trusted by food, cosmetic, and pharmaceutical industries worldwide. With 20+ years of expertise, our factory delivers cutting-edge solutions tailored to high-speed production and sustainability demands.

Why Choose Us?

✅ Advanced Engineering: Multi-cavity molds (up to 144 cavities) with ±0.01mm tolerance, compatible with hot runner systems for seamless mass production.

✅ Material Excellence: Corrosion-resistant steel (420/718H) ensures 2M+ cycles lifespan, ideal for thick-walled jars and lightweight designs.

✅ Quality Assurance: Rigorous trial runs with FDA/EC1935-compliant PET samples. Full-dimension CMM inspection and leak-proof validation.

✅ Customization: Adaptable to PCO, BPF, or proprietary neck finishes. Support eco-friendly designs with 100% recyclable PET.

✅ Global Service: Fast lead time (30-45 days), technical support, and logistics partnerships across 50+ countries.

Applications: Cosmetic jars, nutraceutical containers, food packaging, and household chemical bottles.

Certifications: ISO 9001, ISO 14001, and REACH compliance.

Request a free sample to experience our precision and efficiency – where innovation meets reliability!

| How to place an order for moulds? | |

| 1.R&D | We support customer R&D. Make the files or improve the design if you needed. |

| 2. Quotation Making | Mould Quotation will be finished in 1 day according to the information we get. |

| 3. Negotiation | The quality, price, material, delivery time, payment item, etc. |

| 4. Mould Design | 1-2days for product 3D/2D drawing design as per customer's design. Then in further make the mould 2D/3D design. |

| 5. Mould | 1. confirm the products and the mold design |

| 2. Mould material prepare | |

| 3. Rough machining(heat treatment on mold base and pre-harden on mold) | |

| 4. CNC/ Vacuum Hardening on mold main spare parts | |

| 5. finishing machining( JDPAINT, DEM.etc) | |

| 6. Dimension inspection | |

| 7. Ejector& runner& cooling & other device processes | |

| 8. Assemble mold | |

| 6. Mould Testing | When moulds are finished, we will test the mould and we will send samples to client. |

| 7. Sample confirmation | If the first sample is not satisfied by the customer when it is come out. We modify the mould until meet the customer’s satisfaction. |

| 8. Delivery | Delivery goods by sea or by air, according to customer’s requirement. |